Phosphate-free and sodium-free boiler water treatment agent

A technology for treating chemicals and boiler water, applied in water/sludge/sewage treatment, special treatment targets, descaling and water softening, etc., to reduce boiler blowdown rate, reduce bubble entrainment, and increase PH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Apply the medicament of 10% concentration, and described medicament composition ratio is:

[0042] Polymaleic anhydride 30%;

[0043] Polyepoxysuccinic anhydride 30%;

[0044] Organic ammonia 20%;

[0045] Benzene compound 10%;

[0046] Water 10%.

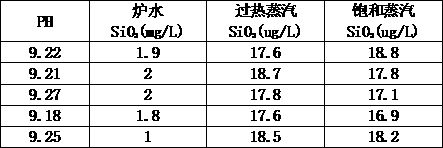

[0047] Carry out 5 experiments, measure SiO in furnace water, superheated steam, saturated steam 2 The content and pH value are respectively:

[0048]

Embodiment 2

[0050] Apply the medicament of 15% concentration, and described medicament composition ratio is:

[0051] Polymaleic anhydride 10%;

[0052] Polyepoxysuccinic anhydride 10%;

[0053] Organic ammonia 30%;

[0054] Benzene compound 30%;

[0055] Water 20%.

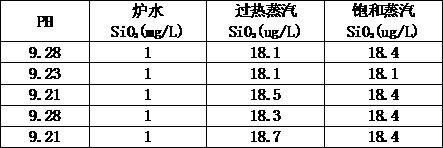

[0056] Carry out 5 experiments, measure SiO in furnace water, superheated steam, saturated steam 2 The content and pH value are respectively:

[0057]

[0058] It can be seen that the data measured in the two examples have played the role of increasing the pH value of condensed water, reducing air bubble entrainment, enhancing steam quality and reducing boiler blowdown rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com