Dewar structure with functions of detection and safety protection

A Dewar structure and safety protection technology, which is applied to the outer wall of the container structure, the method of container discharge, and the details of ship construction, can solve the problems of increased pressure of the Dewar container, potential safety hazards, and icing at the opening, and achieve Reduced cost of use, improved safety, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

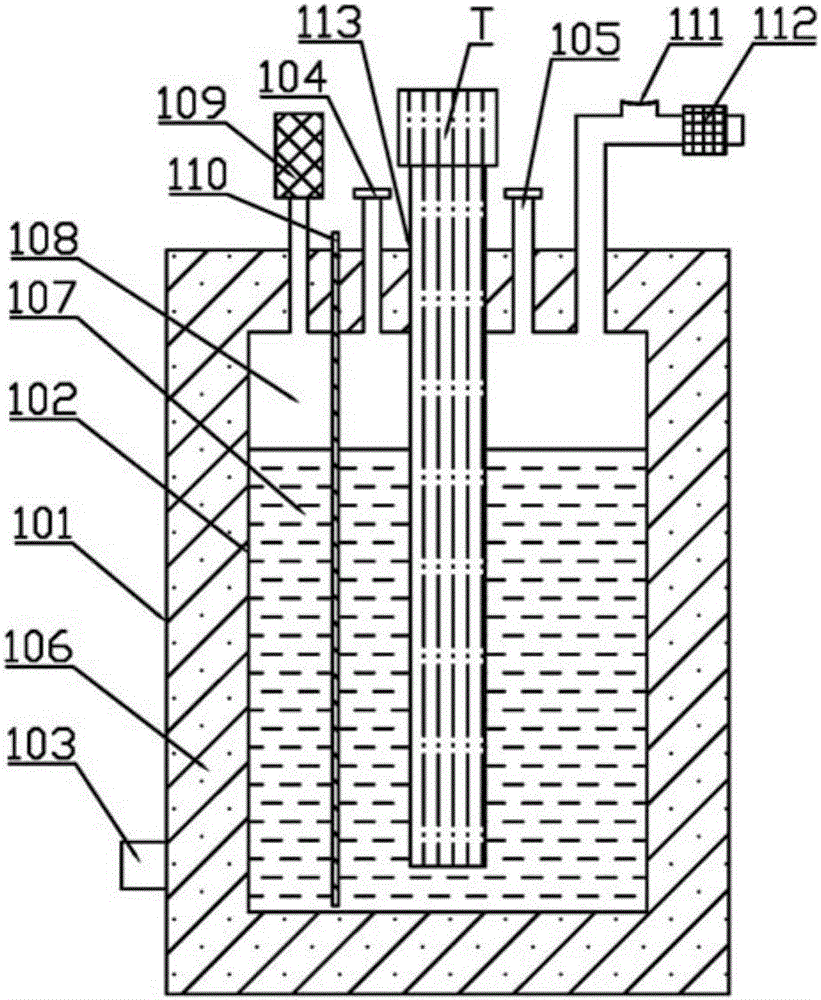

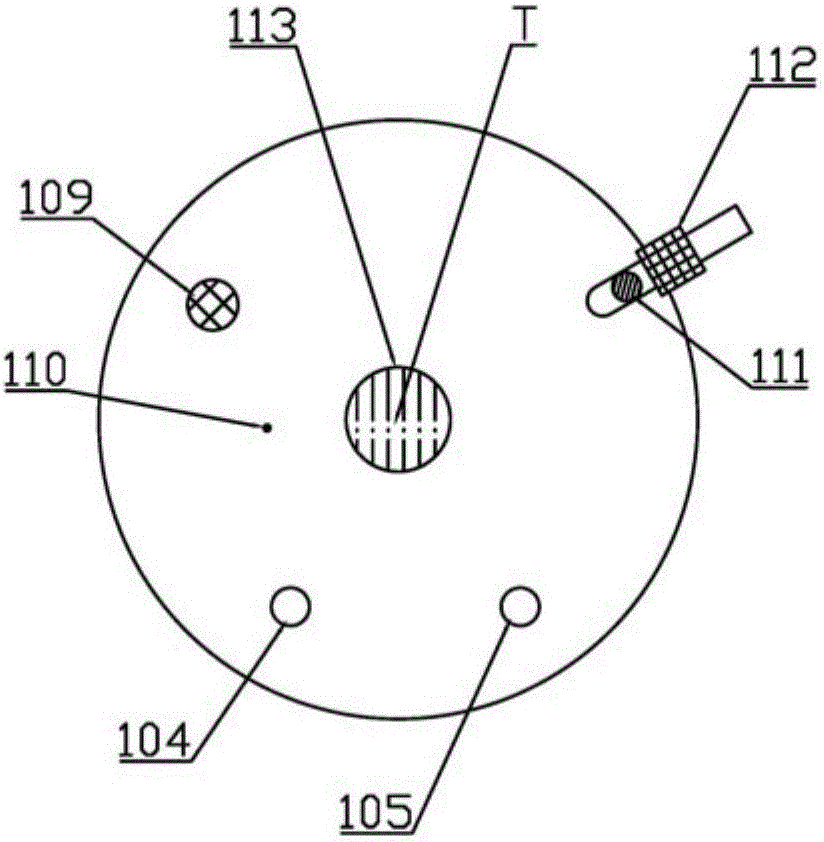

[0025] like figure 1 , figure 2 As shown, the Dewar structure with detection and safety protection of the present invention mainly includes a Dewar tank body composed of a Dewar outer cylinder 101 and a Dewar inner cylinder 102, a pressure sensor 109 and a liquid level gauge 110. A state detection system, a pressure relief system composed of a burst disc 111 and a pressure relief valve 112, and a cold trap adapter interface 113 reserved on the Dewar tank body, and the Dewar tank body is connected to the cold trap T through the cold trap adapter interface 113 . The present invention detects the state of the Dewar tank body in real time through the state detection system, and the excess pressure is discharged in time through the pressure relief system to ensure the normal and safe use of the cold trap T. specifically:

[0026] The Dewar tank body includes a Dewar outer cylinder 101 and a Dewar inner cylinder 102, and a heat insulating layer 106 is arranged in the interlayer ...

Embodiment 2

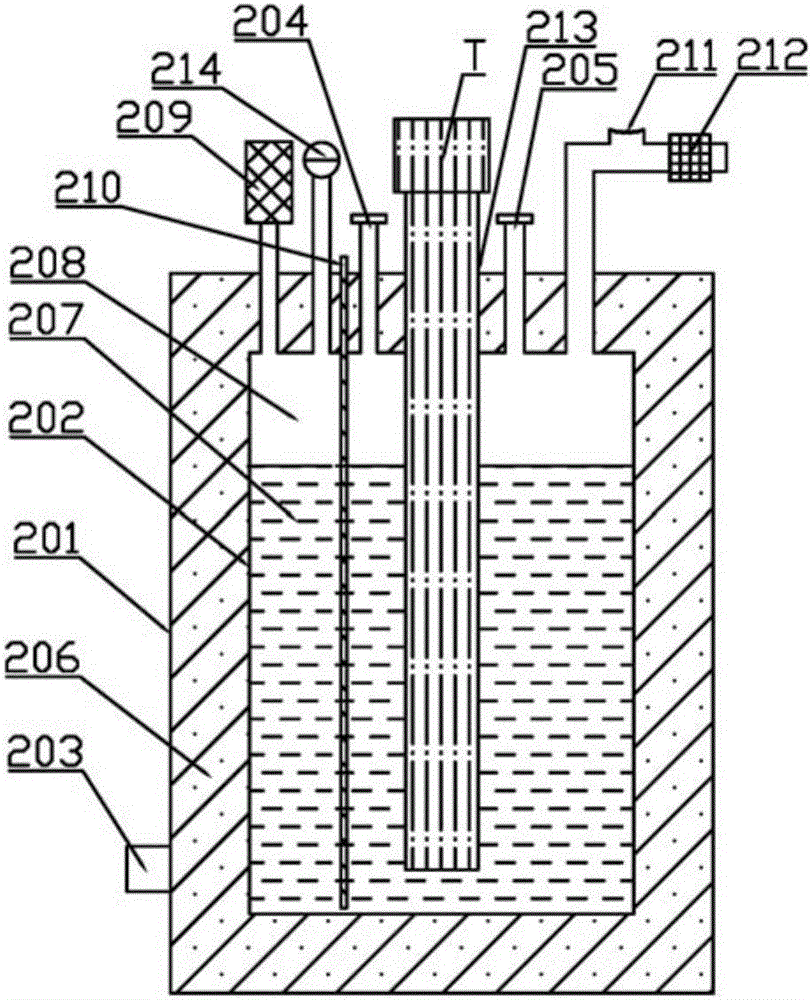

[0035] like image 3 As shown, the Dewar structure with detection and safety protection of the present invention mainly includes a Dewar tank body composed of a Dewar outer cylinder 201 and a Dewar inner cylinder 202, a pressure sensor 209, a liquid level gauge 210 and a pressure sensor 209. A state detection system composed of an indicator gauge 214, a pressure relief system composed of a burst disc 211 and a pressure relief valve 212, and a cold trap adapter interface 213 reserved on the Dewar tank body, and the Dewar tank body passes through the cold trap adapter interface 213 Connect with cold trap T. specifically:

[0036] The Dewar tank body includes a Dewar outer cylinder 201 and a Dewar inner cylinder 202, and an insulating layer 206 is arranged in the interlayer between the Dewar outer cylinder 201 and the Dewar inner cylinder 202, and the Dewar outer cylinder 201 The interlayer between the Dewar inner cylinder 202 is evacuated through the vacuum outlet 203 to the h...

Embodiment 3

[0042] Such as Figure 4 As shown, the Dewar structure with detection and safety protection of the present invention mainly includes a Dewar tank body composed of a Dewar outer cylinder 301 and a Dewar inner cylinder 302, a pressure sensor 309 and a liquid level gauge 310. The state detection system, the pressure relief system composed of the burst disc 311, the mechanical pressure relief valve 314 and the pressure relief valve 312, and the cold trap adapter interface 213 reserved on the Dewar tank body, the Dewar tank body is adapted through the cold trap The interface 213 is connected with the cold trap T. specifically:

[0043] The Dewar tank body includes a Dewar outer cylinder 301 and a Dewar inner cylinder 302, and an insulating layer 306 is provided in the interlayer between the Dewar outer cylinder 301 and the Dewar inner cylinder 302, and the Dewar outer cylinder 301 The interlayer between the Dewar inner cylinder 302 is vacuumed through the vacuum port 303 to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com