load balance measurement

A load balance and load technology, which is applied in measuring devices, force/torque/work measuring instruments, and testing material strength by applying a stable bending force, which can solve high-precision measurement characteristics, low resolution of non-contact measurement, and mechanical problems. Accurate determination of problems such as no breakthrough progress has been achieved, achieving the effects of improved measurement performance, stable measurement performance, and simple measurement structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

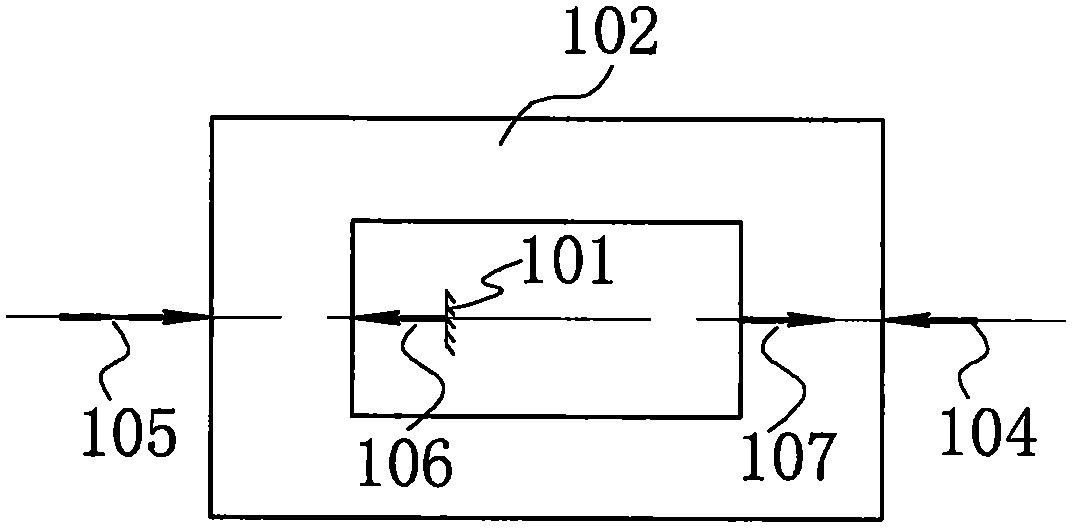

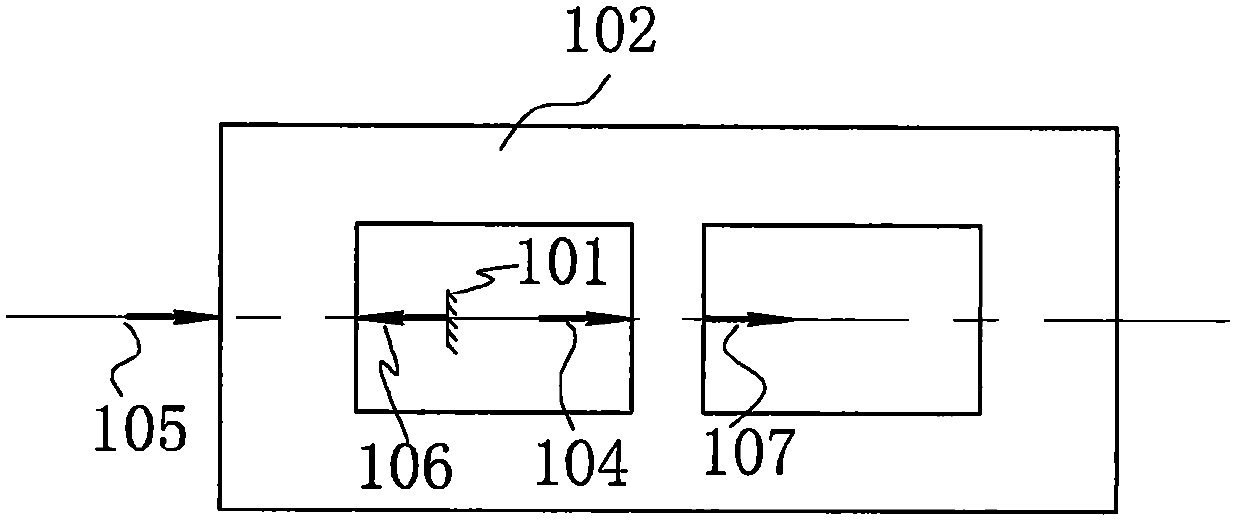

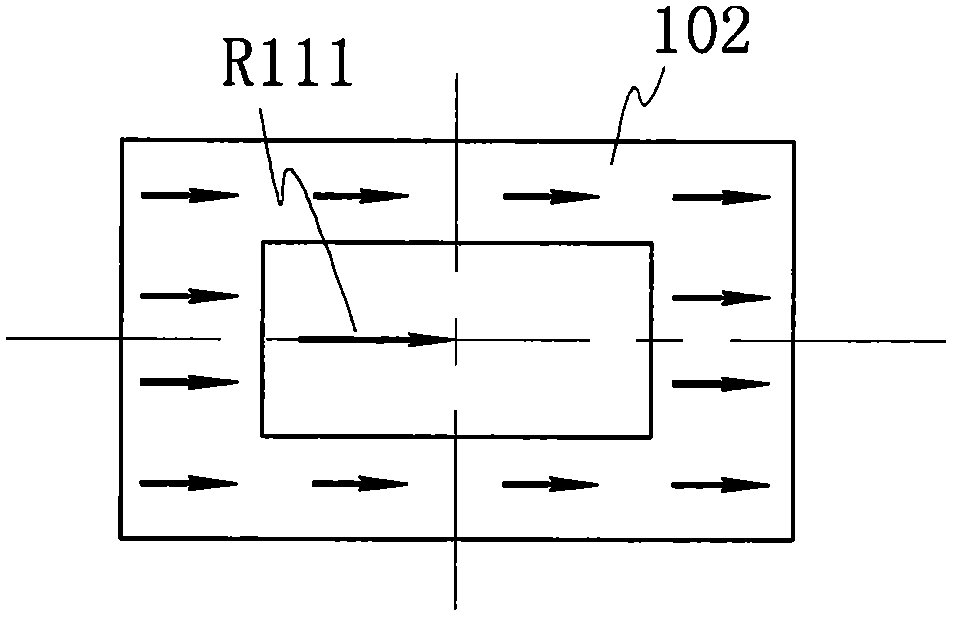

[0057] In order to introduce the technical problems, technical solutions and beneficial effects of the present invention more clearly, the load balance measurement method and several application examples of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

[0058] The rigid load superimposer described in each embodiment of the present invention is a rigid body or non-absolute rigid body that superimposes and transmits the effect of load on it, and it can have various structural forms on the premise of realizing this function. For example, it can be a specific component, or it can be the force-bearing component itself.

[0059] Loads, including single-component or multi-component body loads, line loads, and surface loads. Wherein, the body load includes gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com