Broad bean coat removing device

A technology of guide plate and counter-wheel, which is applied in the fields of application, food processing, food science, etc., can solve problems such as the inability to peel soybeans, and achieve the effect of easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

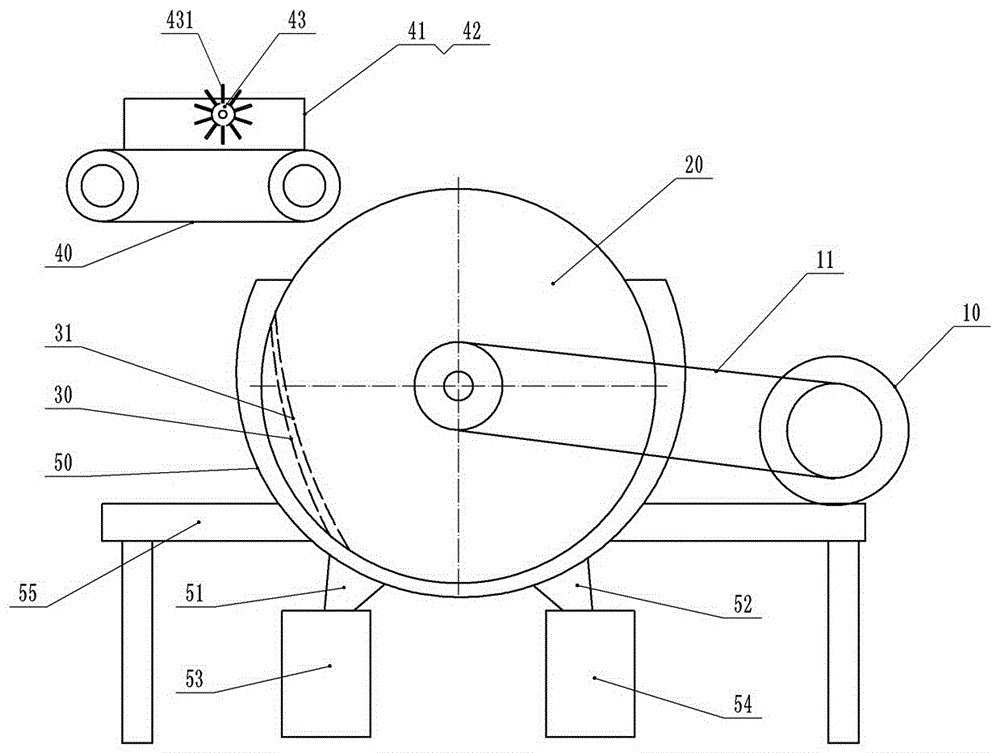

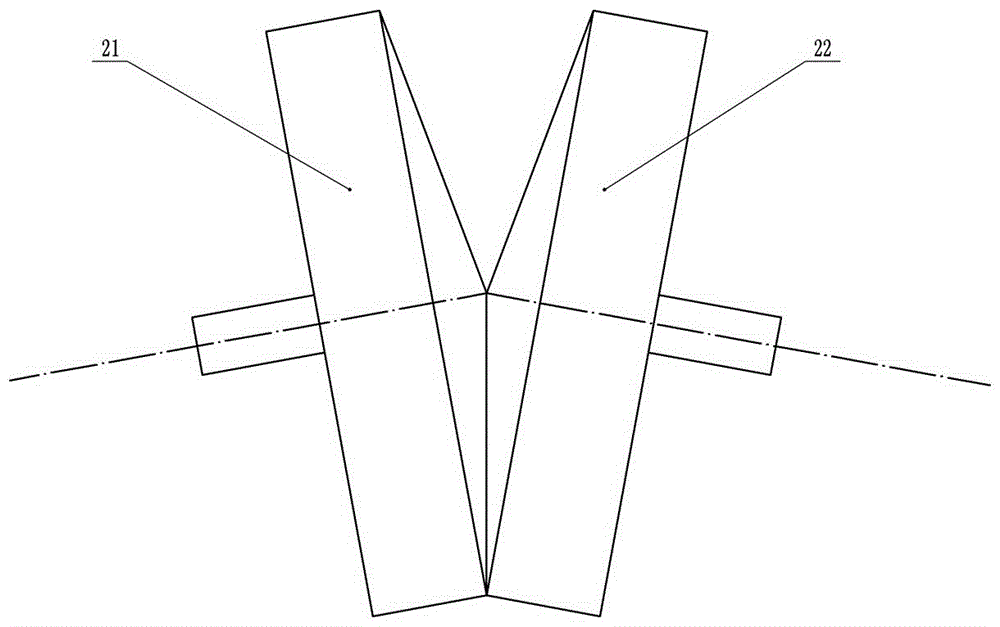

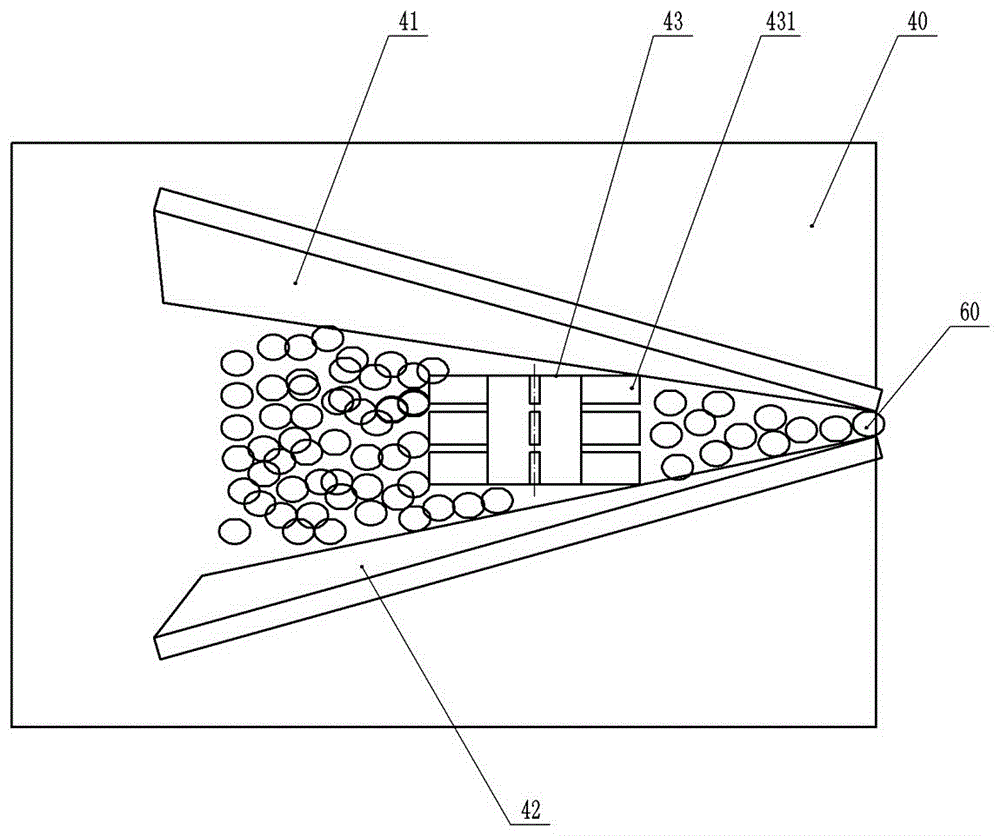

[0019] The reference signs in the accompanying drawings of the description include: motor 10, power transmission part 11, extrusion pair wheel 20, front extrusion wheel 21, rear extrusion wheel 22, processing groove 30, processing cutter head 31, conveyor belt 40, first Guide plate 41, the second guide plate 42, roller 43, blade 431, casing 50, bean outlet 51, bean shell outlet 52, bean collection groove 53, collection shell groove 54, frame 55, soybean 60.

[0020] Such as figure 1 As shown, the soybean peeling device includes a frame 55, a casing 50, a motor 10, a power transmission part 11, a processing tank 30, a processing cutter head 31, an extrusion pair wheel 20, and a soybean transmission mechanism, and the motor passes through the power transmission part 11. Connect with extruding pair wheel 20, extrude pair wheel 20 one side is provided with processing groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com