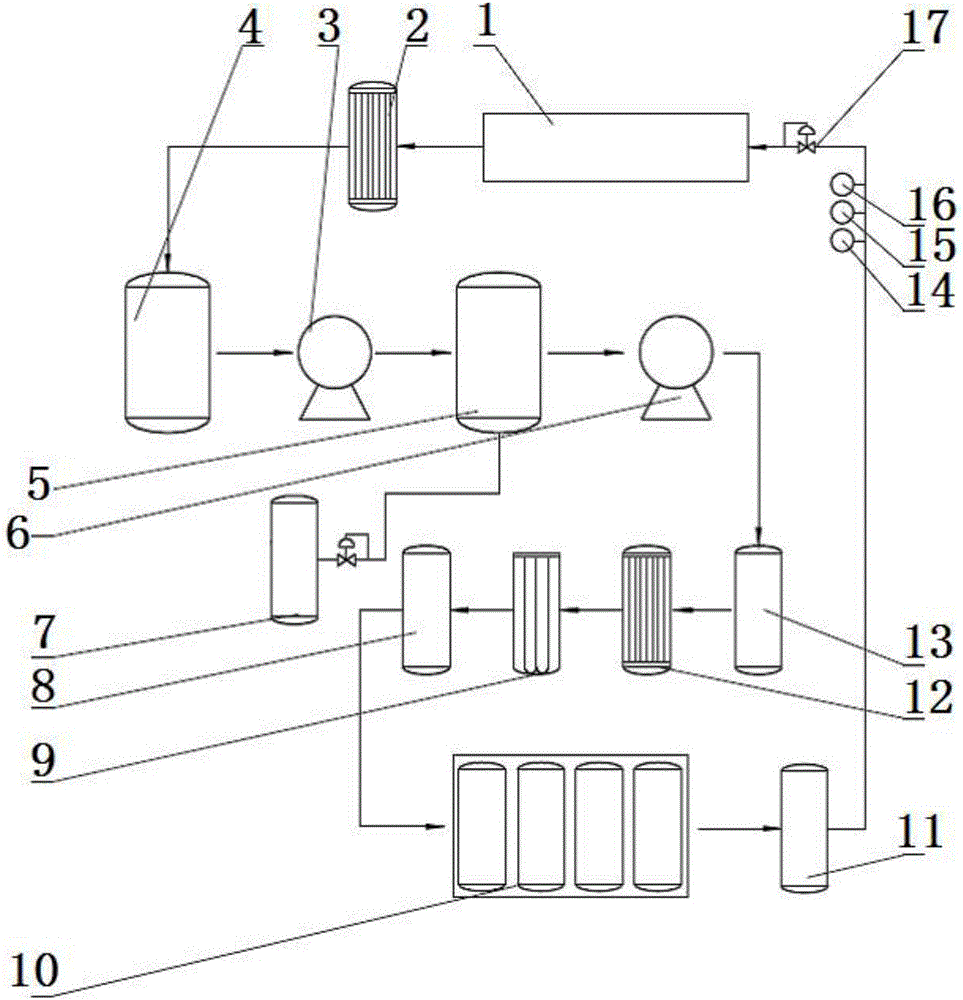

Process for recovering and purifying annealing furnace exhaust gas and device thereof

A tail gas recovery and annealing furnace technology, which is applied to the improvement of process efficiency, furnaces, manufacturing tools, etc., can solve the problems that the tail gas cannot meet the protection gas requirements and the impurity removal effect is poor, so as to improve the impurity removal effect, good dust removal effect, The effect of reducing the difficulty of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a process for recovering and purifying annealing furnace tail gas, including the following steps:

[0045] (1) Condensate the tail gas of the annealing furnace at 10°C, so that the emulsion and rolling oil are condensed into large particles, and the water vapor is condensed into liquid water for removal. At the same time, the emulsion, rolling oil and liquid water will also Wrap and remove part of the dust in the exhaust gas to collect the first exhaust gas;

[0046] (2) Carry out the first filtration treatment to the first tail gas, ensure that the filtration accuracy is 30 μm, remove the larger dust, and further remove the emulsion and rolling oil, and collect the second tail gas;

[0047] (3) Nitrogen is added to the second tail gas to obtain the third tail gas, and the gauge pressure of the third tail gas is guaranteed to be 1Kpa. On the one hand, it plays the role of buffering and stabilizing the pressure, so that the process pressure is stab...

Embodiment 2

[0053] This embodiment provides a process for recovering and purifying annealing furnace tail gas, including the following steps:

[0054] (1) Condensate the tail gas of the annealing furnace at 3°C, so that the emulsion and rolling oil are condensed into large particles, and the water vapor is condensed into liquid water for removal. At the same time, the emulsion, rolling oil and liquid water will also Wrap and remove part of the dust in the exhaust gas to collect the first exhaust gas;

[0055] (2) Carry out the first filtration treatment to the first tail gas, ensure that the filtration accuracy is 10 μm, remove the larger dust, and further remove the emulsion and rolling oil, and collect the second tail gas;

[0056] (3) Nitrogen is added to the second tail gas to obtain the third tail gas, and the gauge pressure of the third tail gas is guaranteed to be 2Kpa. On the one hand, it plays the role of buffering and stabilizing the pressure, so that the process pressure is sta...

Embodiment 3

[0062] This embodiment provides a process for recovering and purifying annealing furnace tail gas, including the following steps:

[0063] (1) Condensate the tail gas of the annealing furnace at 16°C, so that the emulsion and rolling oil are condensed into large particles, and the water vapor is condensed into liquid water for removal. At the same time, the emulsion, rolling oil and liquid water will also Wrap and remove part of the dust in the exhaust gas to collect the first exhaust gas;

[0064] (2) Carry out the first filtration treatment to the first tail gas, ensure that the filtration accuracy is 50 μm, remove the larger dust, and further remove the emulsion and rolling oil, and collect the second tail gas;

[0065] (3) Nitrogen is added to the second tail gas to obtain the third tail gas, and the gauge pressure of the third tail gas is guaranteed to be 0.5Kpa. On the one hand, it plays the role of buffering and stabilizing the pressure, so that the process pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com