Multi-section ammonia-process desulfurization and dust removal absorption tower for flue gas of carbon furnace and coke oven

A technology of ammonia desulfurization and absorption tower, which is applied in the field of ammonia desulfurization and dust removal absorption tower, can solve the problems of ammonium sulfate escape, reduce processing efficiency, and high energy consumption of ammonium sulfate, and achieve the effect of solving ammonium sulfate escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention are described in detail as follows:

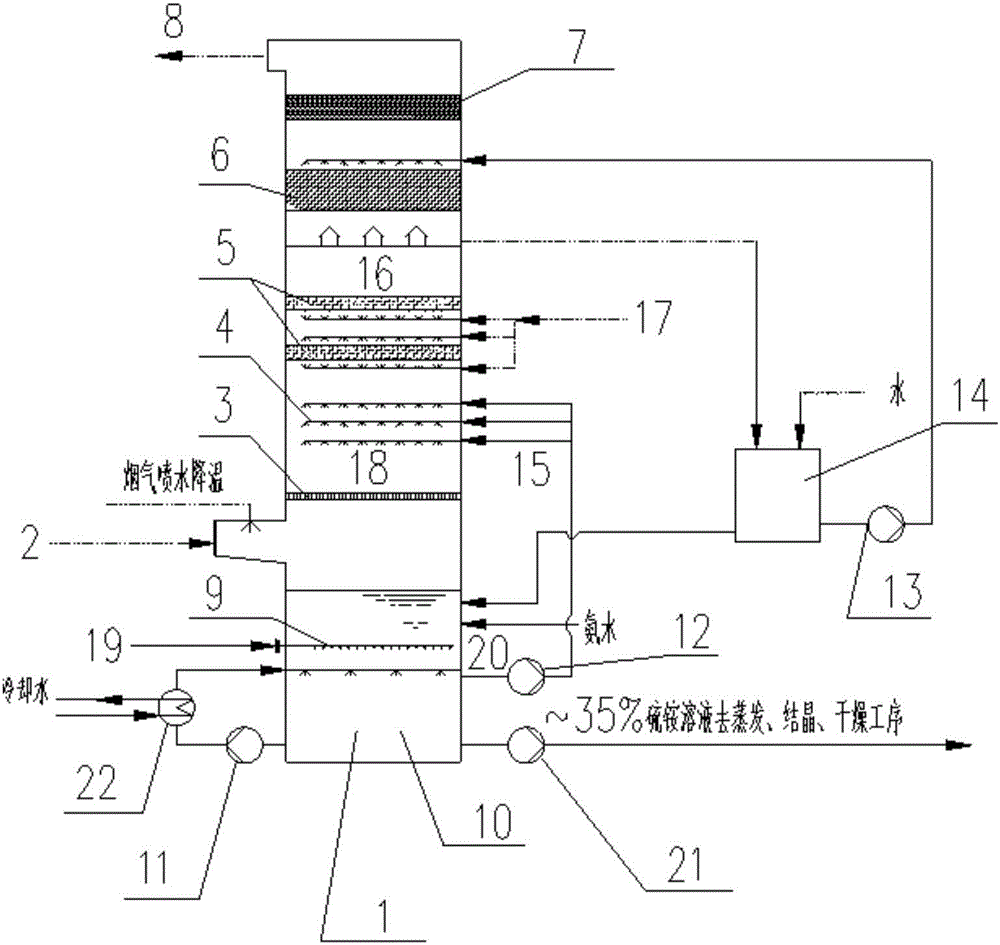

[0032] In this example, see figure 1 , a carbon furnace, coke oven flue gas multi-stage ammonia desulfurization and dust removal absorption tower, composed of the bottom of the absorption tower 1, the middle tower body and the tower top, the lower part of the middle tower body of the absorption tower 1 is provided with a flue gas inlet 2, A water spray cooling device is provided at the flue gas inlet 2, and a flue gas outlet 8 is arranged on the top of the absorption tower 1, and the net flue gas that reaches the emission standard after desulfurization and purification treatment of the absorption tower 1 is discharged from the flue gas outlet 8, and then An oxidation pool 10 is set at the bottom of the absorption tower 1, and the internal desulfurization and purification treatment system of the absorption tower 1 adopts a countercurrent spraying and packed absorption tower structure, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com