Method and device for conducting impact crushing on brittle fine granular layers through pneumatic dielectric spheres

A technology of impact pulverization and medium ball, which is applied in the field of medium ball impact pulverization of fine particle material layer, which can solve the problems of large difference, difficult to guarantee the thickness of material layer, and limited particle size of particle crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

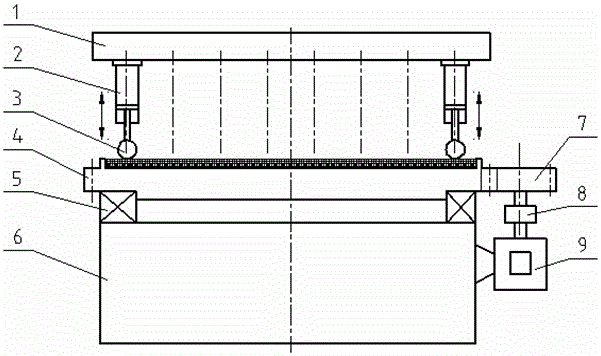

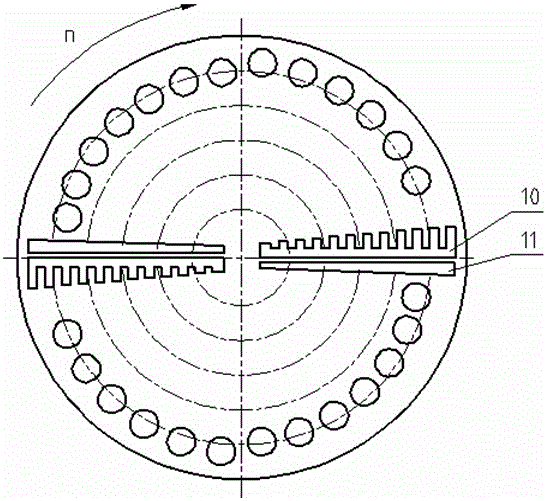

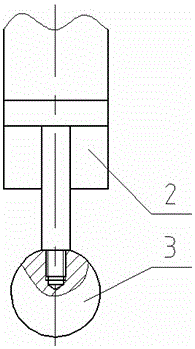

[0021] Such as Figure 1 to Figure 5 As shown, the device for crushing the brittle fine particle layer by pneumatic medium ball impact includes a high-frequency reciprocating cylinder impact system (including air source, pressure control valve, speed control valve, upper support seat 1, reciprocating cylinder 2, medium ball 3, ), material table rotary system (including rotary material table 4, slewing bearing 5, lower support 6, pinion 7, coupling 8, motor 9), material layer loosening and negative pressure screening system (comb type loose plate 10 and negative pressure screening mechanism), feeding and material layer arrangement system (including hopper and material layer laying mechanism 11).

[0022] During implementation, determine the material layer thickness, medium ball diameter and impact stress according to the particle size and impact strength of the particles; set the negative pressure value of the negative pressure screening system according to the particle size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com