Laser-electric arc composite welding real-time regulation and control system and regulation and control method thereof

A hybrid welding and real-time control technology, applied in the field of material engineering, can solve problems such as lack of fusion, burn-through, and incomplete penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

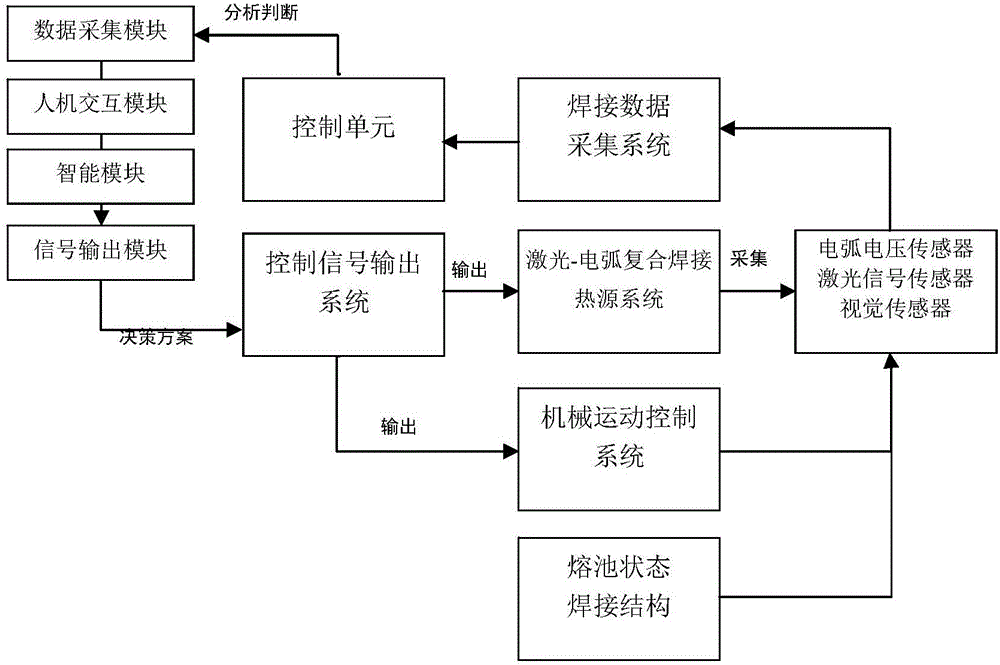

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

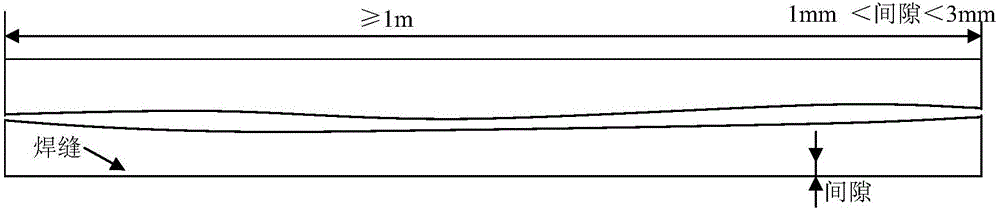

[0034] Example 1: Irregular straight line structure welding

[0035] like figure 2 Shown is an irregular long straight weld that approximates a straight line. In a large number of actual engineering structures, with the increase of the actual structure length, the straight weld shows obvious irregularities in the welding manufacturing process, and because the specimen is larger In actual engineering manufacturing, the method similar to robot trial teaching has significantly affected the welding efficiency. To address the above problems, use the visual sensor of the welding process of the present invention to initially obtain the macroscopic structure of the actual test piece, collect the structural shape of the test piece to be welded in the real-time welding process, and determine a reasonable welding path according to the actual gap between the plate groups. Due to the large gaps in the plates, the single use of weld seam tracking cannot effectively solve the problem of la...

example 2

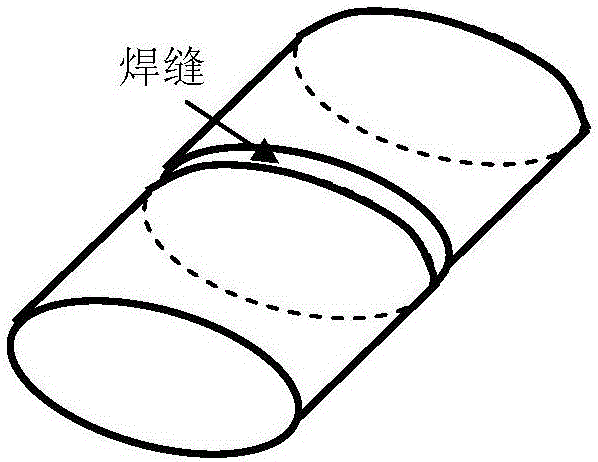

[0040] Example 2: Welding of complex space structures

[0041] like image 3 Shown is a complex elliptical space surface structure, which is basically manufactured by segmented welding in the traditional welding manufacturing process. Discontinuous welds affect the efficiency and quality of welding manufacturing to a certain extent. However, in order to realize the continuous welding of this structure, the test piece itself needs to cooperate with the movement. The welding process is the combination of the rotating movement of the test piece and the curved movement of the welding torch. Since the actual components are not completely symmetrical, the During the manufacturing process, the linear speed of the welding torch will also change with the movement of the test piece, and the coordinated control between the welding curve and the speed must be realized during actual welding. Not only that, in actual welding, the angle between the laser-arc hybrid welding torch and the tes...

example 3

[0045] Example 3: Penetration welding of T-shaped structural parts

[0046] Titanium alloy T-shaped structure (such as Figure 4 (shown) that is, the penetration welding of the wall plate and rib structure is mainly arc welding at first. During the welding process, the single arc welding current is very large, and the welded structural parts are obviously deformed under the condition of large heat input. have a significant impact. The present invention can change the energy state of the heat source formed between the laser and the arc by adjusting the angle between the laser and the electric arc and changing the angle α between the laser and the electric arc, thereby significantly improving the overall penetration of the heat source. Aiming at the problems of poor welding penetration energy, slow speed and large deformation in the arc welding process, the present invention focuses on the regulation of the following aspects:

[0047] ①The welding heat source, according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com