A kind of compound kiln changing glaze glaze material, compound kiln changing glaze Jun porcelain and preparation method thereof

A technology for kiln-changing glaze and glaze, which is applied in the fields of composite kiln-changing glaze glaze, composite kiln-changing glaze Jun porcelain and its preparation, which can solve the problem that the composite kiln-changing glaze cannot be applied well, and the artistic ornamental and commercial value of Jun porcelain cannot be improved. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

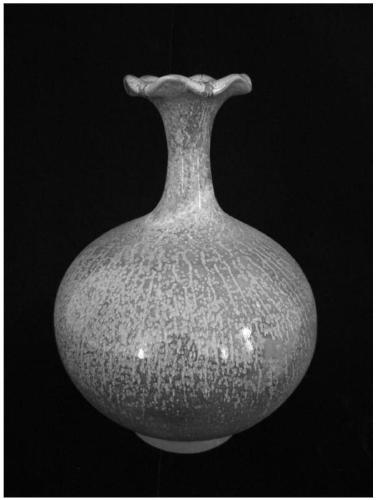

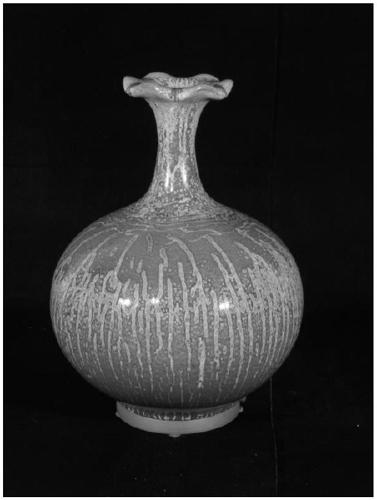

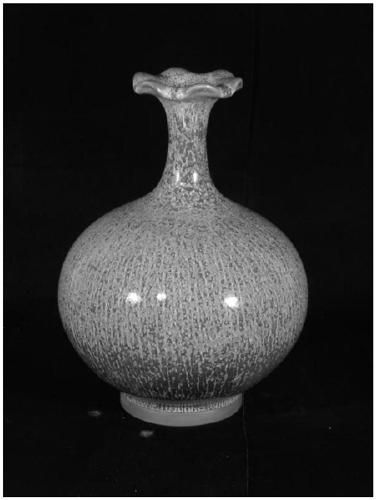

Image

Examples

preparation example Construction

[0052] The present invention also provides a preparation method of composite kiln-changed glazed Jun porcelain, comprising the following steps:

[0053] a) Mix the underglaze glaze material described in the above technical scheme with water, perform the first ball milling and the first sieving in sequence to obtain the underglaze slurry; the sieve hole size of the first sieving is 300 mesh, and the first The sieved balance shall not exceed 0.5%;

[0054] b) Mix the surface glaze glaze material described in the above technical scheme with water, carry out the second ball milling and the second sieving in sequence to obtain the surface glaze slurry; the sieve hole size of the second sieving is 180 mesh, and the second The sieved balance shall not exceed 0.5%;

[0055] c) Mix the transparent glaze material described in the above technical scheme with water, and perform the third ball milling and the third sieving in order to obtain the transparent glaze slurry; the sieve size of...

Embodiment 1

[0090] (1) The formula of composite kiln variable glaze is as follows:

[0091] Bottom glaze: 45 parts by weight of potassium feldspar, 12 parts by weight of sandstone, 12 parts by weight of copper ore, 3 parts by weight of copper oxide, 13 parts by weight of calcite, 3 parts by weight of kaolin, 5 parts by weight of zinc oxide, 2 parts by weight of tin oxide Parts by weight, 1 part by weight of chromium oxide, 1 part by weight of talc, 3 parts by weight of bovine bone meal;

[0092] Surface glaze: 20 parts by weight of potassium feldspar, 25 parts by weight of Yushan feldspar, 17 parts by weight of sandstone, 26 parts by weight of calcite, 1.5 parts by weight of copper oxide, 3 parts by weight of kaolin, 5 parts by weight of zinc oxide, and 1.5 parts by weight of tin oxide Parts by weight, 1 part by weight of talc;

[0093] Transparent glaze: 45 parts by weight of potassium feldspar, 12 parts by weight of sandstone, 32 parts by weight of calcite, 3 parts by weight of kaolin,...

Embodiment 2

[0109] (1) The formula of composite kiln variable glaze is as follows:

[0110] Bottom glaze: 48 parts by weight of potassium feldspar, 10 parts by weight of sandstone, 10 parts by weight of copper ore, 2 parts by weight of copper oxide, 17 parts by weight of calcite, 4 parts by weight of kaolin, 4 parts by weight of zinc oxide, 1 part by weight of tin oxide Parts by weight, 1 part by weight of chromium oxide, 1 part by weight of talc, 2 parts by weight of bovine bone meal;

[0111] Surface glaze: 18 parts by weight of potassium feldspar, 27 parts by weight of Yushan feldspar, 15 parts by weight of sandstone, 27 parts by weight of calcite, 2 parts by weight of copper oxide, 2 parts by weight of kaolin, 6 parts by weight of zinc oxide, 2 parts by weight of tin oxide Parts by weight, 1 part by weight of talc;

[0112] Transparent glaze: 40 parts by weight of potassium feldspar, 14 parts by weight of sandstone, 34 parts by weight of calcite, 5 parts by weight of kaolin, 3 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com