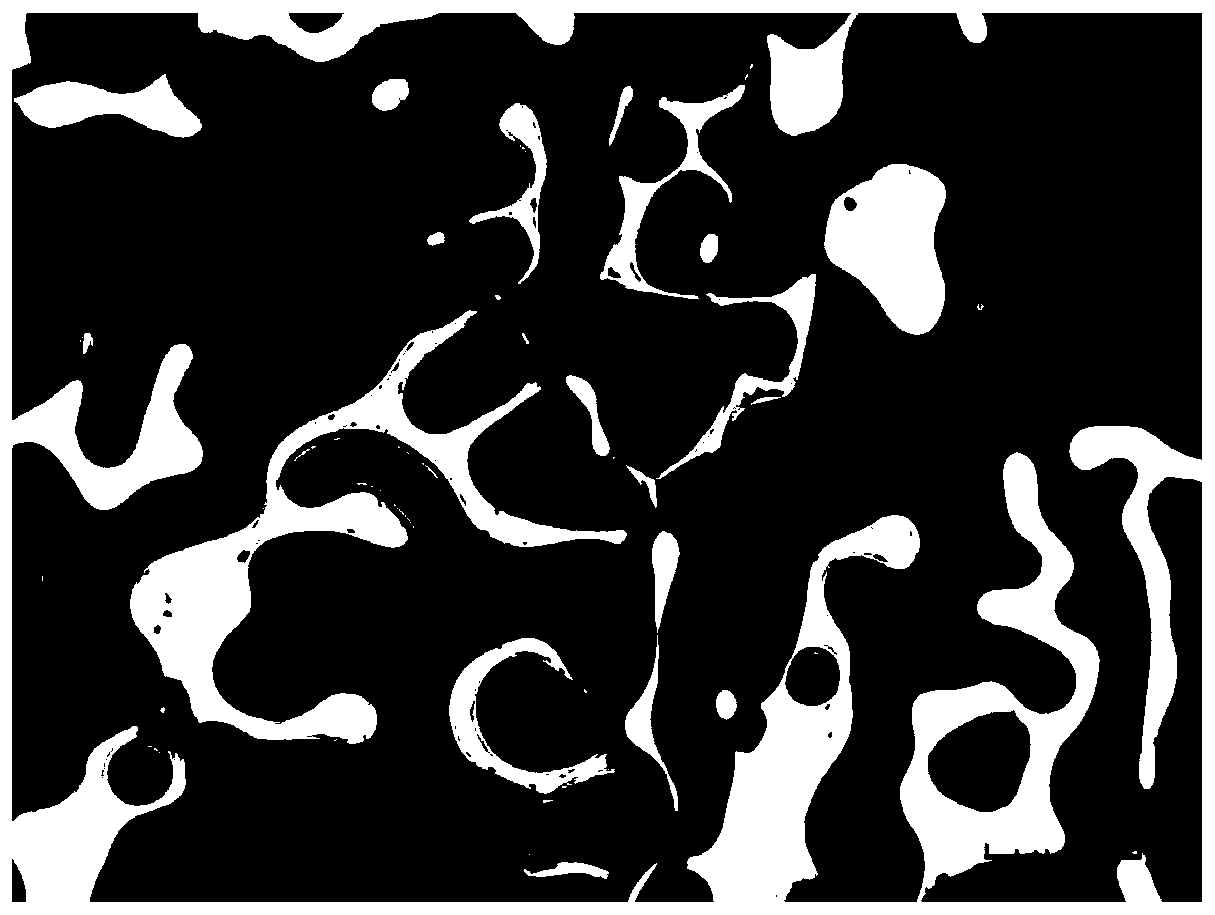

a porous b 4 cCeramic skeleton and its frozen injection molding process

A ceramic skeleton and process technology, applied in the field of porous B4C ceramic skeleton preparation technology, can solve the problems of low material strength, complicated operation, low C content, etc., and achieve reliable mechanical strength and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

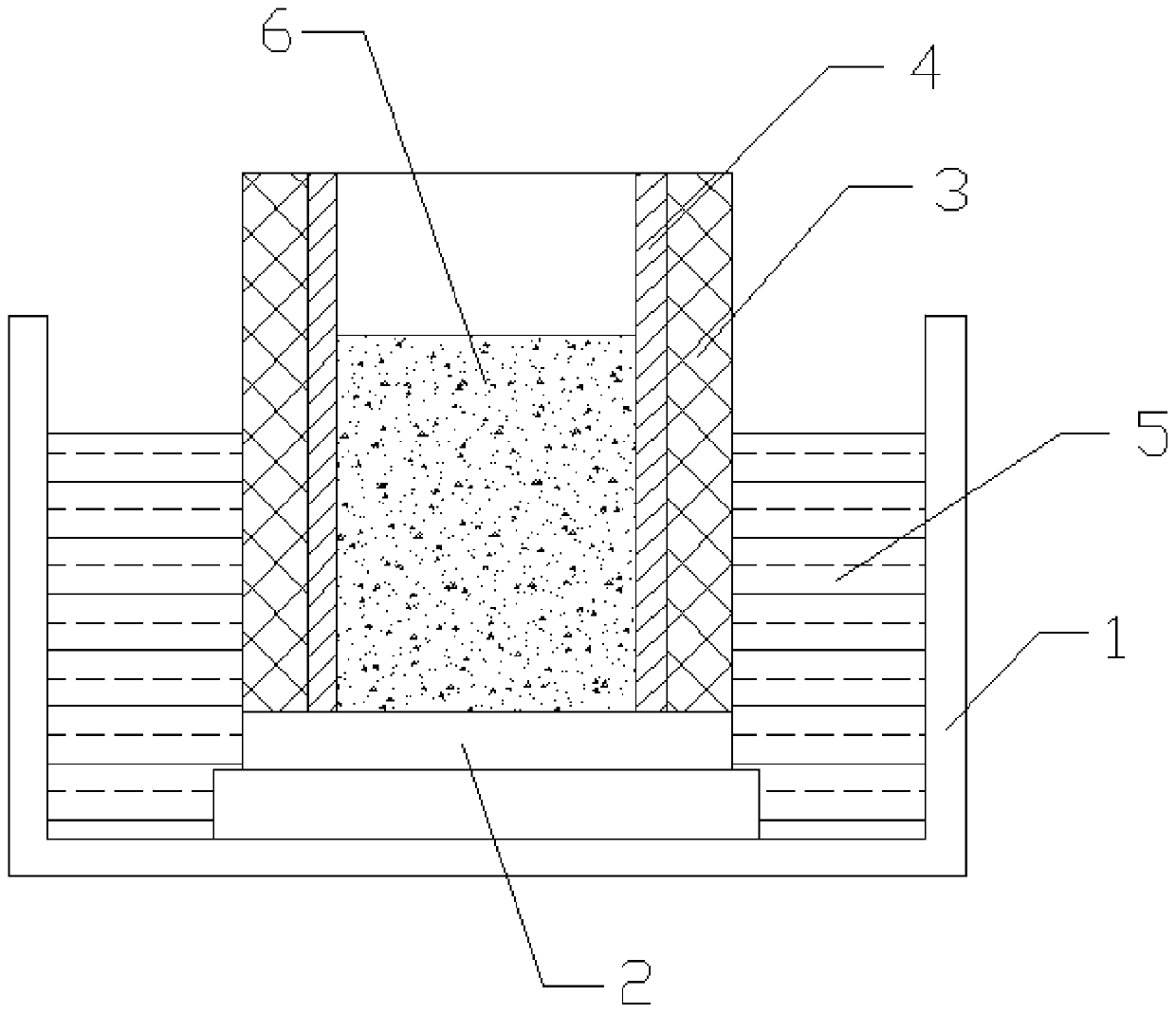

[0021] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

[0022] reference sign

[0023] Freezing container 1, metal bottom plate 2, thermal insulation foam 3, polytetrafluoroethylene mold 4, freezing aid 5, ceramic slurry 6.

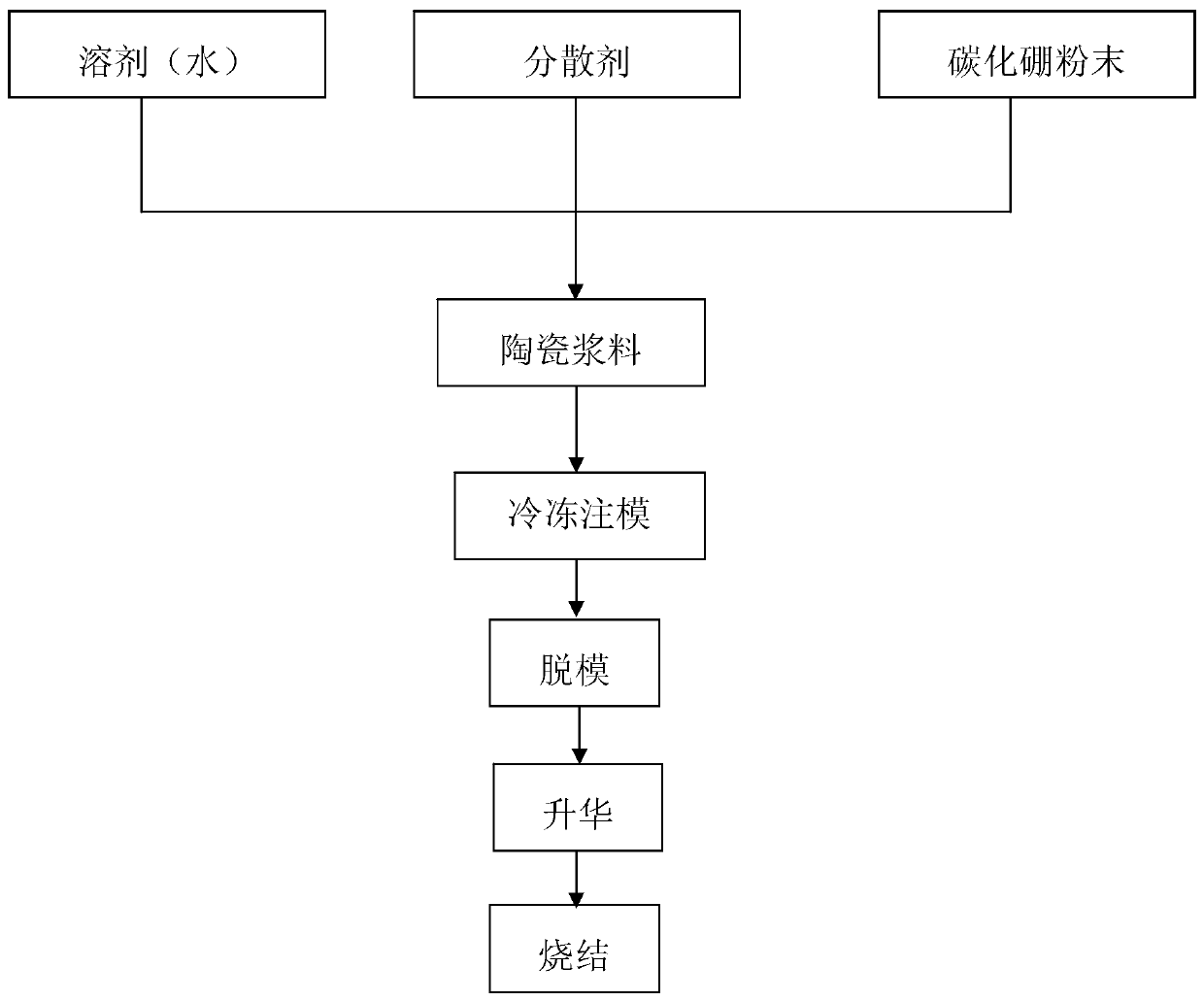

[0024] The invention relates to a method for preparing neutron absorbing material B 4 Porous B of C / Al 4 C The frozen injection molding process of the ceramic skeleton, in this process: water is used as a solvent, B 4 For C powder, choose powders with four different particle sizes of 5μm, 10μm, 20μm, and 40μm to mix. 4 The molar percentage of C powder is 8:4:2:1, polyvinyl alcohol is used as a dispersant, liquid nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com