A kind of super-chemical-resistant PC/ABS alloy material and preparation method thereof

A technology of alloy materials and chemicals, which is applied in the field of super chemical-resistant PC/ABS alloy materials and its preparation, can solve the problems of poor chemical resistance, high processing cost, poor resistance to industrial chemicals, etc., and achieve chemical resistance Enhanced properties, improved compatibility, and the effects of meeting chemical resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

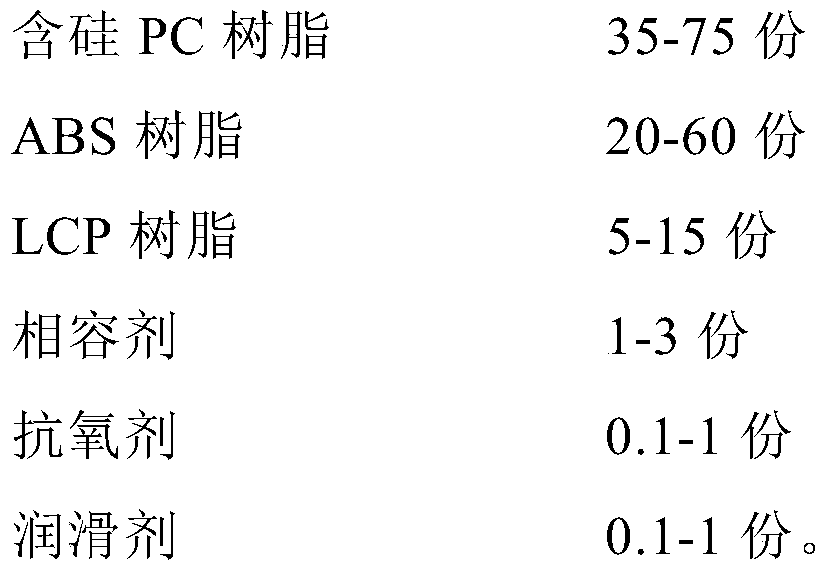

Method used

Image

Examples

Embodiment 2

[0023] In embodiment 2, silicon-containing PC resin is polycarbonate-organic silicon random copolymer, and relative molecular weight is 22000, and silicon content is 6wt%, and ABS resin is acrylonitrile-butadiene-styrene copolymer, butadiene The content is 15 wt%, and the LCP resin is a polyimide type thermotropic liquid crystal polymer material.

Embodiment 3

[0024] In embodiment 3, silicon-containing PC resin is polycarbonate-organic silicon random copolymer, and relative molecular weight is 25000, and silicon content is 8wt%, and ABS resin is acrylonitrile-butadiene-styrene copolymer, butadiene The content is 30 wt%, and the LCP resin is a polyamide type thermotropic liquid crystal polymer material.

Embodiment 4

[0025] In embodiment 4, silicon-containing PC resin is polycarbonate-organic silicon random copolymer, and relative molecular weight is 30000, and silicon content is 10wt%, and ABS resin is acrylonitrile-butadiene-styrene copolymer, butadiene The content is 55 wt%, and the LCP resin is a polyester imide type thermotropic liquid crystal polymer material.

[0026] The specific preparation method is:

[0027] (a) preparing materials according to the formula, adding each raw material into a mixer, stirring for 10-20 minutes, and mixing evenly to obtain a mixture;

[0028] (b) blending and granulating the mixture through a twin-screw extruder, wherein the barrel temperature of the twin-screw extruder is controlled at 200-260° C., and the screw speed is controlled at 300-600 rpm.

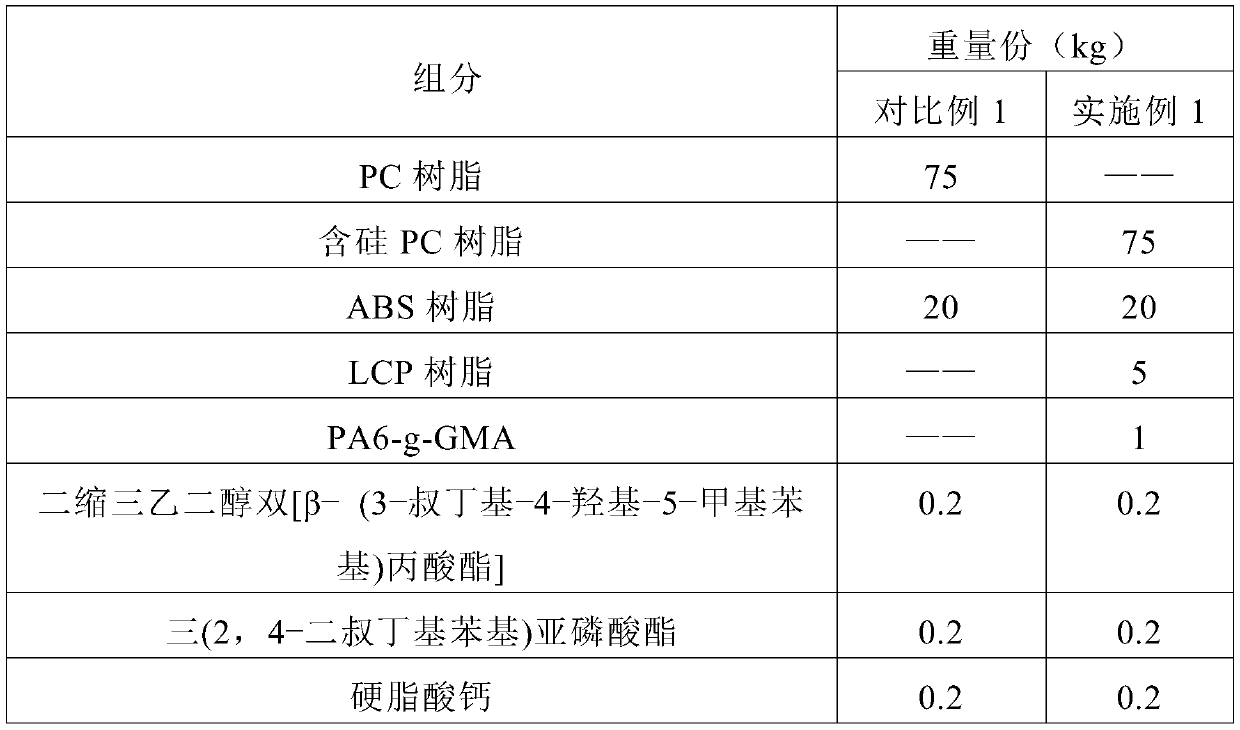

[0029] Table 1 comparative example 1 and embodiment 1 formula

[0030]

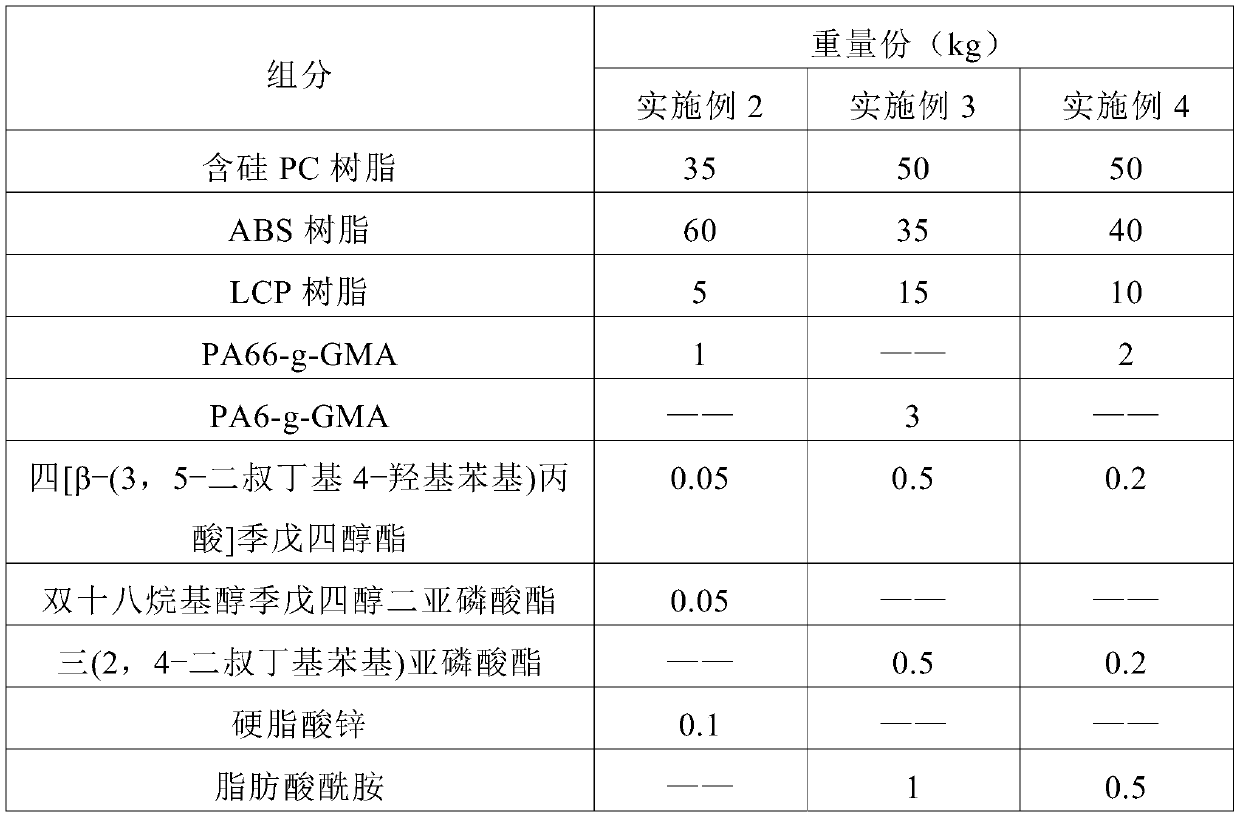

[0031] Table 2 Embodiment 2-4 formula

[0032]

[0033] The PC / ABS alloy material prepared in Comparative Example 1 and Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com