Waterborne over-printing gold varnish and preparation technology thereof

A preparation process and technology for varnishing gold, applied in the field of printing ink, can solve the problems of reduced crosslinking density, reduced abrasion resistance of varnished gold oil, poor compatibility, etc., to improve compatibility and avoid easy yellowing , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Add the following components in parts by mass, 30 parts of modified water-based acrylic resin emulsion, 30 parts of modified water-based polyurethane resin emulsion, 1 part of neutralizer A and deionized water into a high-speed mixer, and stir at 1000r / min for 10min ;

[0044] (2) Add 10 parts of methyl etherified amino resin emulsion, 1 part of wear-resistant additive A, 1 part of hardening additive, and 0.5 parts of defoamer A into step (1), and stir at 800 r / min for 15 min;

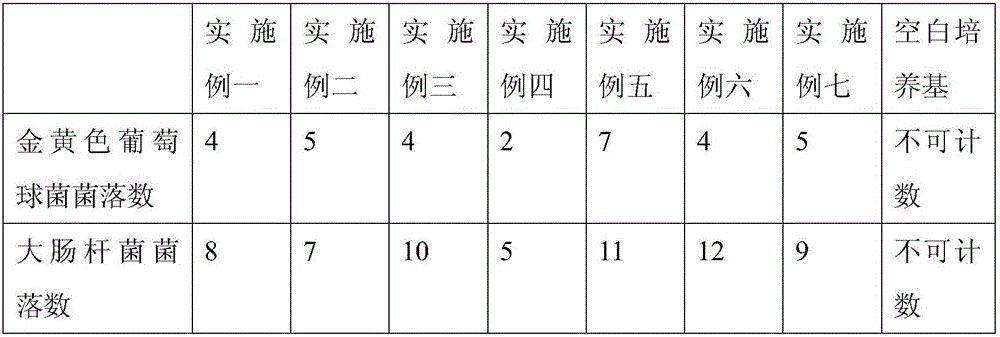

[0045] (3) Add 0.5 parts of fungicide A to step (2), and continue to stir for 2 minutes;

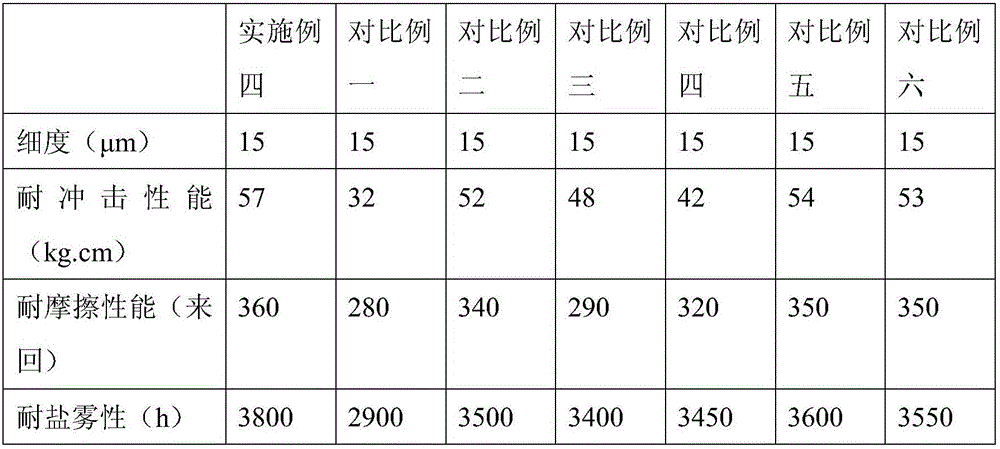

[0046] (4) After the stirring is completed, grind to a fineness of less than 15 μm by a sand mill to obtain the water-based overprint gold oil.

[0047] (4) After the stirring is completed, grind to a fineness of less than 15 μm by a sand mill to obtain the water-based overprint gold oil.

Embodiment 2

[0049] (1) Add the following components in parts by mass, add 35 parts of modified water-based acrylic resin emulsion, 35 parts of modified water-based polyurethane resin emulsion, 2 parts of neutralizer B and deionized water into the high-speed mixer, and stir at 900r / min 12min;

[0050] (2) Add 12 parts of methyl etherified amino resin emulsion, 3 parts of anti-wear additive B, 2 parts of hardening additive, and 0.3 parts of defoamer B into step (1), and stir at 1400 r / min for 20 min;

[0051] (3) Add 0.2 parts of fungicide B to step (2), and continue to stir for 3 minutes;

[0052] (4) After the stirring is completed, grind to a fineness of less than 15 μm by a sand mill to obtain the water-based overprint gold oil.

Embodiment 3

[0054] (1) Add the following components in parts by mass, add 40 parts of modified water-based acrylic resin emulsion, 40 parts of modified water-based polyurethane resin emulsion, 5 parts of neutralizer C and deionized water into a high-speed mixer, and stir at 800r / min 15min;

[0055] (2) Add 15 parts of methyl etherified amino resin emulsion, C5 parts of wear-resistant additive, C4 parts of hardening additive, and C3 parts of defoamer into step (1), and stir at 1250 r / min for 13 min;

[0056] (3) Add 0.3 parts of bactericide C to step (2), and continue to stir for 2.5 minutes;

[0057] (4) After the stirring is completed, grind to a fineness of less than 15 μm by a sand mill to obtain the water-based overprint gold oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com