Hot-melt pressure-sensitive adhesive for backing adhesive bag and preparation method thereof

A hot-melt pressure-sensitive adhesive and plastic bag technology, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of affecting product appearance, low bonding strength, and adhesive bag loss. Achieve low toxicity, high peel strength, softness and good electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of above-mentioned hot-melt pressure-sensitive adhesive is, and it comprises the steps:

[0023] a. Weigh each component of the raw material according to the formula, put dioctyl terephthalate, antioxidant 1010 and DLTP into the reaction kettle, stir and heat;

[0024] b. When the heating temperature reaches 145±5°C, slowly add SIS, stir for 5 minutes after adding, then add 1 / 3 of the total amount of C5 petroleum resin; continue to stir and heat to 165±5°C, keep the temperature at 25 rpm Stir for 150±10 minutes under the condition of 10 minutes; keep the temperature range of 165±5°C because if the temperature is too low, it will lead to incomplete melting and SIS agglomeration, and if the temperature is too high, it will cause unsaturated double bonds in SIS. Thermal oxidation will occur and degrade, reducing the cohesive strength of the adhesive.

[0025] c. Under the condition of temperature control and stirring, add the remaining 2 / 3 amount of...

Embodiment

[0029] Selection of raw materials: The base resin SIS is 3433N SIS (tri-block copolymer of styrene-isoprene-styrene) produced by ZEON CORPORRION in Japan, and its SI content is 56%. The grade of tackifier C5 petroleum resin is 3200 from Ningbo Jinhai Chenguang. Antioxidant 1010 and antioxidant DLTP are selected from Nanjing Jingtianwei Chemical Co., Ltd.

[0030] The following are the formulas of several groups of raw materials (in kg):

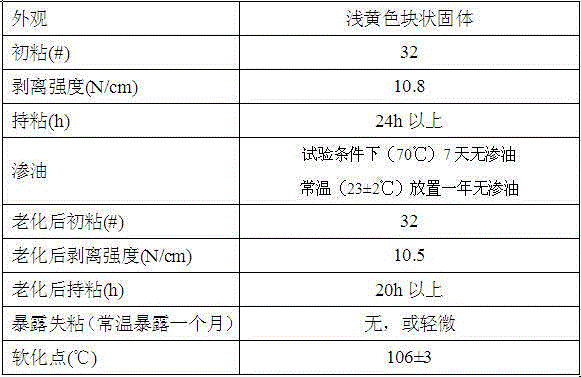

[0031] Table 1 List of five formulations of hot-melt pressure-sensitive adhesives

[0032]

[0033] The preparation method of hot melt pressure sensitive adhesive is as follows:

[0034] a. Weigh each component according to the ratio of Example 3, take dioctyl terephthalate, antioxidant 1010, and DLTP into the reaction kettle, stir and heat; b. When the heating temperature reaches 145°C, slowly add Styrene-isoprene-styrene tri-block copolymer, after stirring for 5 minutes, add 17kg of modified aliphatic C5 petroleum resin; continue to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com