Method for extracting germanium and removing chlorine in zinc sulfate solution

A zinc sulfate solution and zinc sulfate technology, applied in the direction of improving process efficiency, etc., can solve the problems of low removal efficiency, complicated process, high cost, etc., and achieve the effect of simple process method, high extraction rate, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

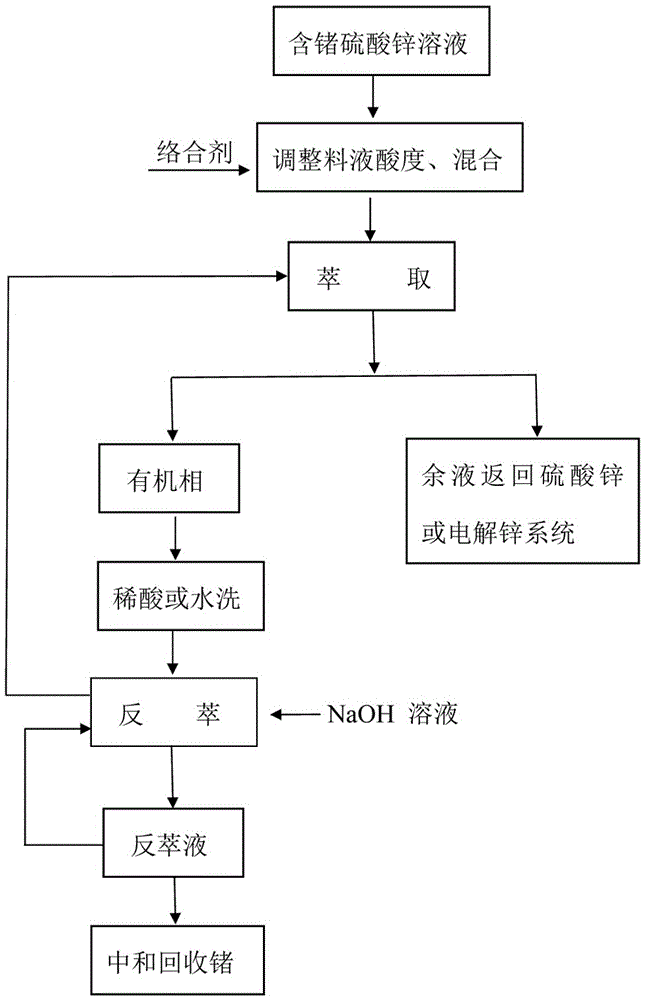

Image

Examples

preparation example Construction

[0038] 2) Preparation of mixed extractant: Mix N235, 2-octanol and sulfonated kerosene evenly to prepare a mixed extractant. The volume of N235 in the mixed extractant is 5-40%, and the volume of 2-octanol is 3~10%, the balance is sulfonated kerosene;

[0039] 3) Extraction: Add the mixed extractant prepared in step (2) to the mixed solution obtained in step (1), mix thoroughly, extract, and separate to obtain the organic phase and residual liquid. The amount of the mixed extractant added is 0.3 to 3 times the volume of the solution, and the remaining liquid is returned to the zinc sulfate or electrolytic zinc system;

[0040] 4) Water washing and stripping: wash the organic phase obtained in step (3) with dilute acid or water, and then use a stripping agent for stripping to obtain a stripping liquid, and then neutralize and precipitate the stripping liquid to recover germanium.

[0041] The germanium-containing zinc sulfate solution described in step (1) is the germanium-con...

Embodiment 1

[0056] The method of the present invention is implemented in Yunnan Yesheng Environmental Resources Technology Co., Ltd., and the results are as follows:

[0057] Raw materials: feed liquid 30m³, containing sulfuric acid [H + 】17.86g / l, 【Cl - 】819mg / l, 【Ge 4+ 】223.83mg / l.

[0058] process:

[0059] 1) Complexation: Add complexing agent tartaric acid to the germanium-containing zinc sulfate solution (feed liquid), the addition amount is 10 times the content of germanium, and then mix it well to control the acidity of the solution at 10~100g / l to obtain a mixed solution ;

[0060] 2) Preparation of mixed extractant: Mix N235, 2-octanol and sulfonated kerosene evenly to prepare a mixed extractant. In the mixed extractant, the volume of N235 is 5%, and the volume of 2-octanol is 10%. , the balance being sulfonated kerosene;

[0061] 3) Extraction: Add the mixed extractant prepared in step (2) to the mixed solution obtained in step (1), mix thoroughly, perform four-stage coun...

Embodiment 2

[0065] The method of the present invention is implemented in Yunnan Yesheng Environmental Resources Technology Co., Ltd., and the results are as follows:

[0066] Raw materials: 200 cubic meters of feed liquid, containing sulfuric acid [H + 】15.25g / l, 【Cl - 】2460mg / l, 【Ge 4+ 】104.59mg / l.

[0067] process:

[0068] 1) Complexation: Add complexing agent tartaric acid to the germanium-containing zinc sulfate solution (feed liquid), the addition amount is 8 times the content of germanium, and then fully mix it to control the acidity of the solution at 10~100g / l to obtain a mixed solution ;

[0069] 2) Preparation of mixed extractant: Mix N235, 2-octanol, modifier and sulfonated kerosene evenly to prepare a mixed extractant. The volume of N235 in the mixed extractant is 30%, and the volume of 2-octanol Parts by volume are 8%, the modifying agent of 2% by volume, and the balance is sulfonated kerosene; the modified agent is ethyl octanol;

[0070] 3) Extraction: Add the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com