Preparation method of anti-atomization micrometer and nanometer composite structure copper-based super-hydrophobic surface

A micro-nano composite structure, super-hydrophobic surface technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of complex processing procedures, failure of super-hydrophobic properties, poor stability, etc., to achieve a wide range of applications Prospects, excellent macroscopic hydrophobicity, effect of protecting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] 1. Experimental technical plan

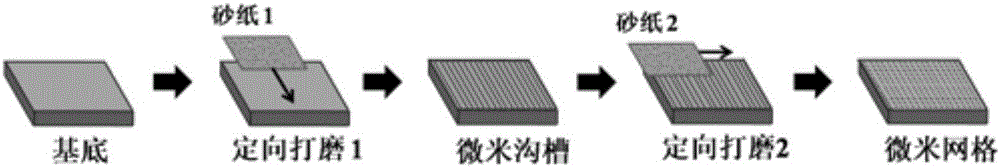

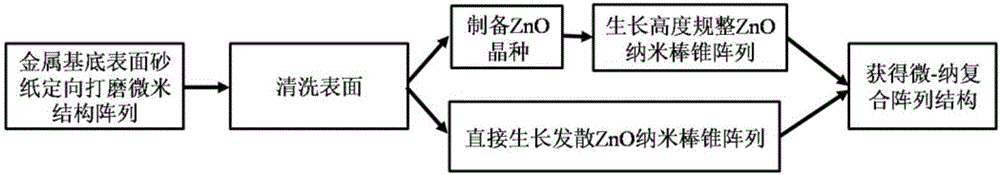

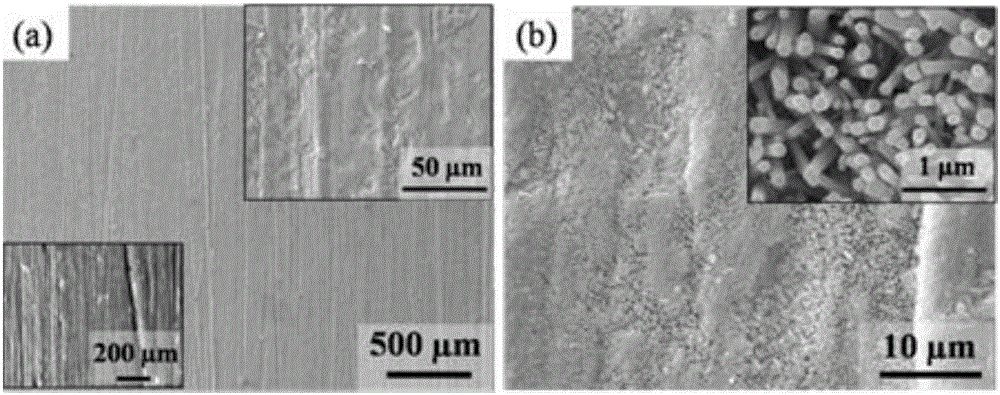

[0042] A method for preparing an anti-fog micro-nano composite structure copper-based super-hydrophobic surface, using copper foil as the base, first using water-grinding paper to press figure 1 Directional grinding of metal copper substrates in the manner shown, constructs regular micron grooves or micron mesh rough structures on the substrate surface; subsequently, according to figure 2 The shown process prepares a regular ZnO nanorod cone array structure on the copper surface with a micron-scale rough structure, thereby constructing a micro-nano hierarchical composite structure on the surface of the copper substrate; finally, heptadecafluorodecyltrimethoxysilane (FAS -17) Perform high-temperature vacuum fluorination on the copper substrate with the micro-nano composite structure to obtain the anti-fog micro-nano composite structure copper-based super-hydrophobic surface. Proceed as follows:

[0043] (1) Construction of the micron a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com