Preparation method and application of corrosion-resistant and fog-resistant copper-based super-hydrophobic surface with nest-shaped structure

A super-hydrophobic surface, fog bird technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., to achieve broad application prospects, strong super-hydrophobic performance, and anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

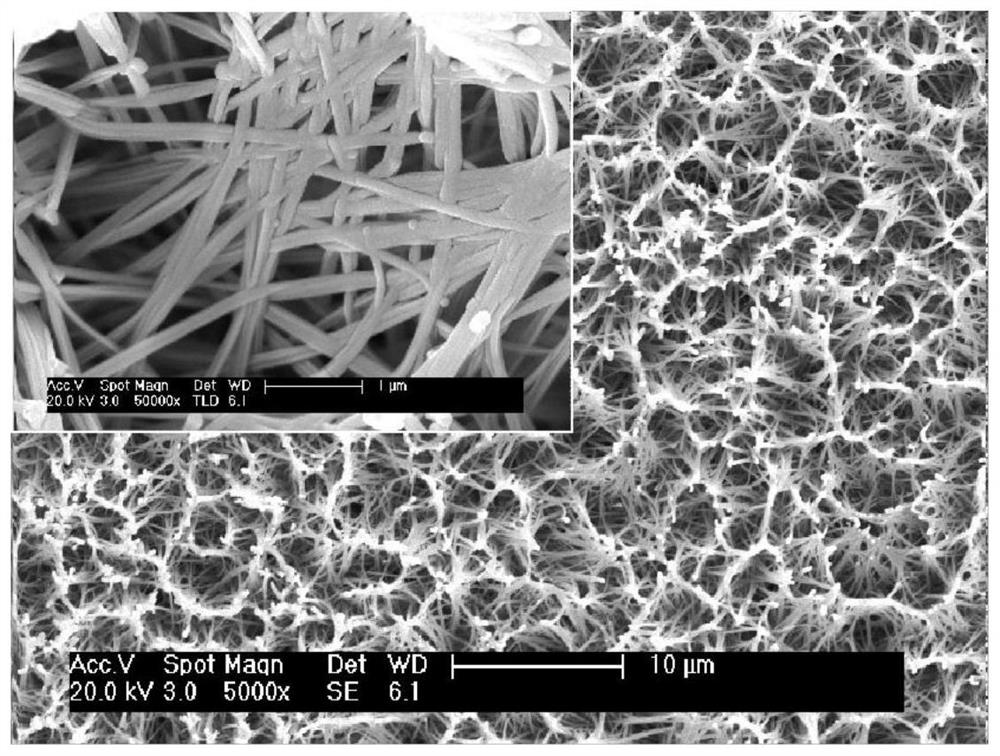

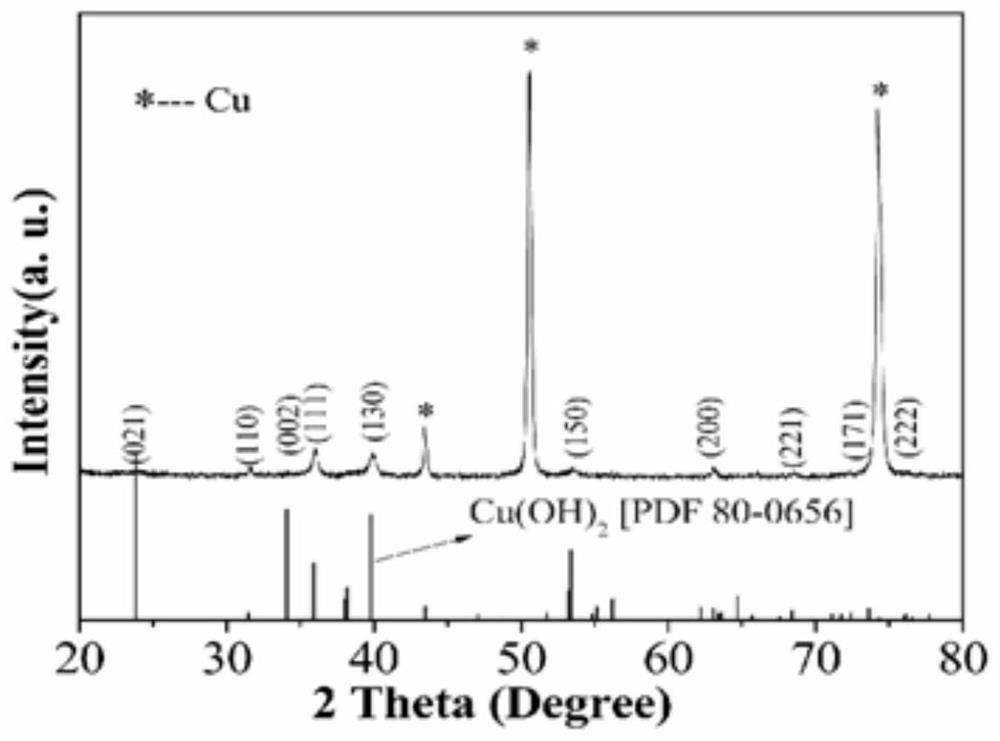

[0042] A method for preparing a corrosion-resistant and anti-fog bird's nest structure copper-based super-hydrophobic surface, comprising the following specific steps:

[0043] S1. Prepare very dilute ammonia solution: use deionized water as a single solvent to prepare 100 mL of 0.005 mol / L dilute ammonia solution;

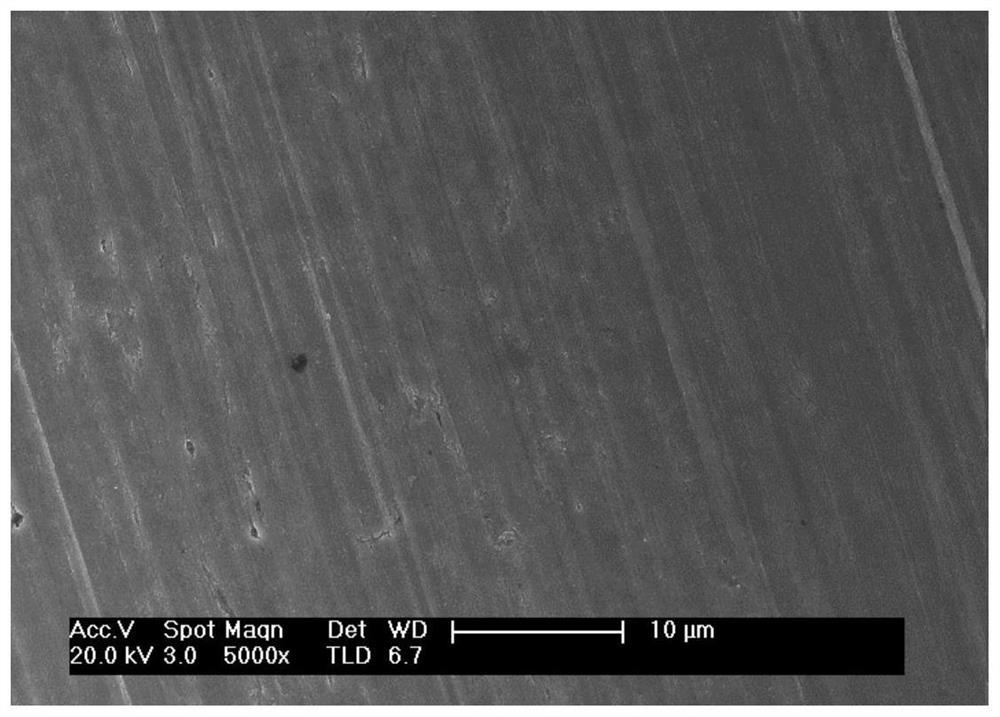

[0044] S2. Copper pretreatment: The 28.46mm×26.63mm×0.24mm copper substrate is ultrasonically cleaned with acetone, absolute ethanol and deionized water for 8 minutes to remove dust and oil on the surface; then use 0.08mol / L hydrochloric acid The solution is corroded for 45 seconds to remove the oxide layer on the surface of the copper; then rinse with tap water and deionized water in sequence to remove the residual hydrochloric acid on the surface of the copper;

[0045] S3, rinsing treatment: the red copper after the above pretreatment is rinsed with absolute ethanol and air-dried to form a protective layer on the surface of the red copper to avoid re-oxidation;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com