Textile finishing method

A technology for fabric finishing and fabric finishing agent, applied in dyeing, fiber treatment, textile and papermaking, etc., can solve the problems of large water consumption and energy consumption, and achieve the effect of saving consumption, poor fluidity and improving water retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and advantages of the present invention more obvious and comprehensible, specific implementations of the present invention will be described in detail below. The reagents and raw materials used in Examples and Comparative Examples are commercially available.

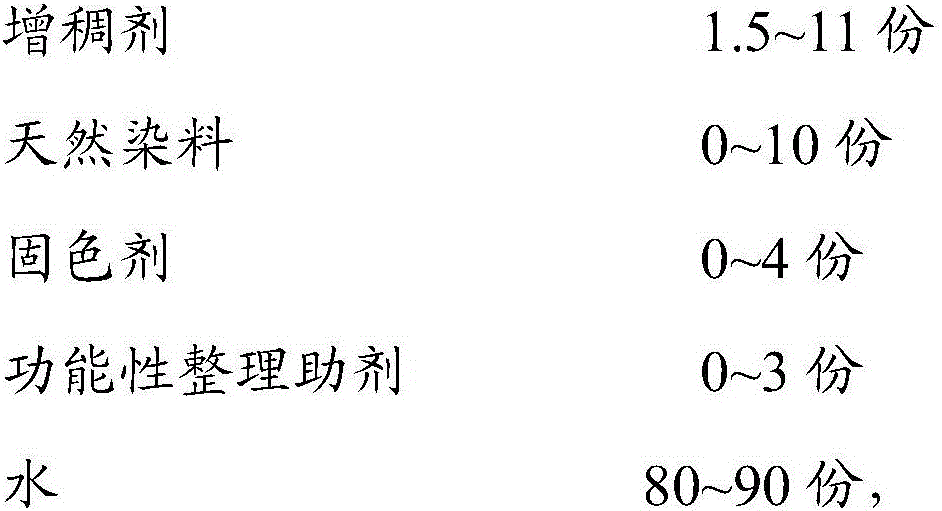

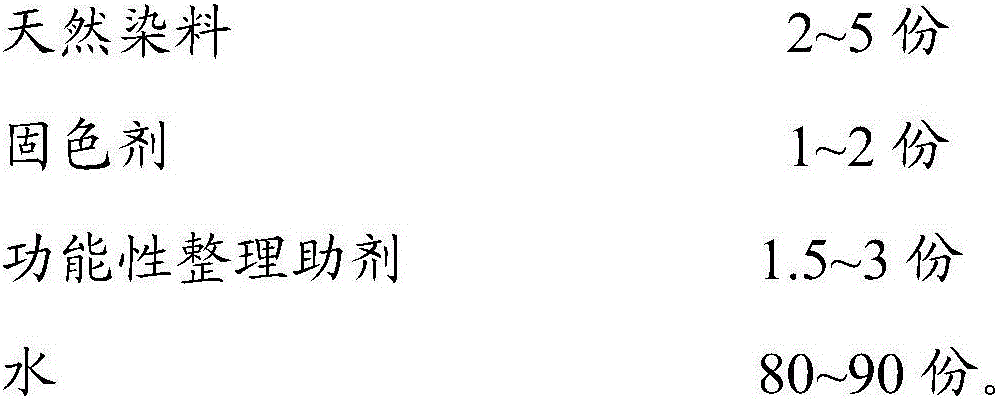

[0032] Embodiment one to embodiment four, the parts by weight of each component of the environment-friendly fabric finishing agent of comparative example one to comparative example six are shown in Table 1:

[0033] Table I

[0034]

[0035]

[0036] A method for fabric finishing, which is used for real silk, wool, cotton, hemp, regenerated cellulose fiber fabrics and blended interwoven fabrics, the specific steps are:

[0037] Fabric dipping—steaming—washing—drying—finished product.

[0038] Fabric dipping: the fabric is dipped in the environment-friendly fabric finishing agent described in Example 1 to Example 4, Comparative Example 1 to Comparative Example 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com