Anchor drilling machine independent rack for machine

A technology for bolting rigs and racks, which is used in the installation of bolts, drilling equipment, earth-moving drilling, etc., can solve the problems of strong shock and vibration, inoperability, damage to the bolting machine, etc., and achieves increased strength and rigidity. Compact structure Effects of design, enhanced stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

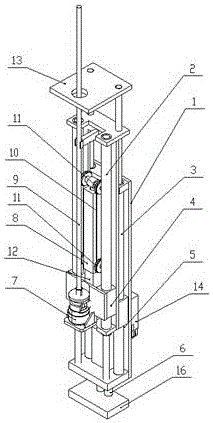

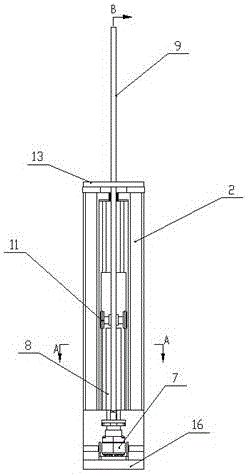

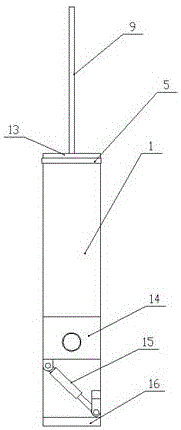

[0037]As shown in the drawings, the technical solution adopted by the present invention includes a drilling rig frame 1, on which a sliding guide rail 5, a first guide post oil cylinder 3, a side swing bracket 14 and a side swing oil cylinder 15 are installed. The second guide post oil cylinder 2, the drilling rig sliding bracket 4 and the drilling rig oil cylinder 12 are installed on the 5, and the bolt drill 7 is installed on the drilling rig sliding bracket 4. The sliding guide rail 5 is composed of a perforated upper cover 5-1, a back plate 5-2, bottom plate 5-3 and perforated slider 5-4, the second guide post oil cylinder 2 is installed between the perforated upper cover plate 5-1 and the bottom plate 5-3, and the piston of the second guide post oil cylinder 2 The rod is fixedly connected to the bottom plate of the drilling rig frame 1, the slide block 5-4 with holes slides on the cylinder block of the first guide column oil cylinder 3, and the upper cover plate 5-1 with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com