Engine particulate purification regeneration control system

A regenerative control and engine technology, applied in the direction of engine components, combustion engines, machines/engines, etc., to achieve the effect of narrowing the filter bandwidth, overcoming the problem of insufficient reliability, and prolonging the life of the filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific drawings.

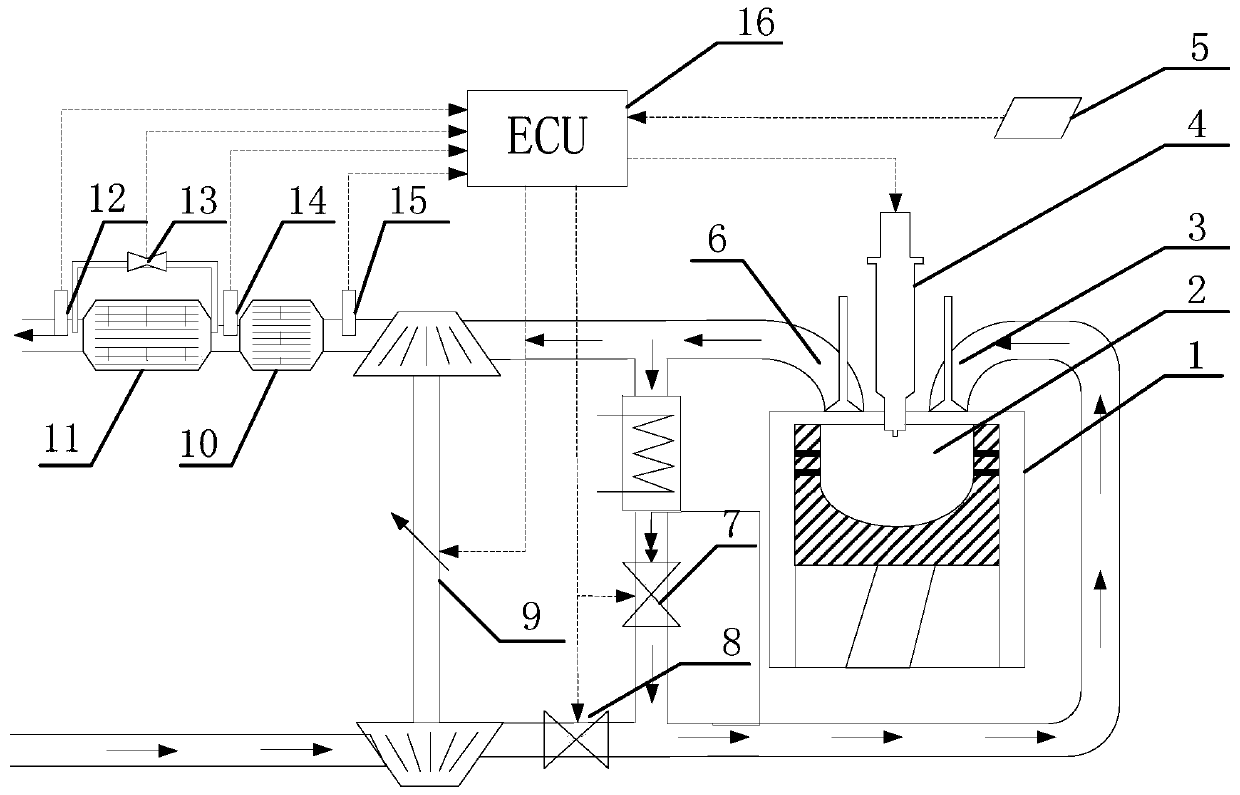

[0034] Such as figure 1 Shown is the post-treatment layout of a diesel engine equipped with a particle supplementary collection system. The diesel engine 1 is equipped with a throttle valve 8, a variable cross-section supercharger 9, and an exhaust gas recirculation system with cooling in the intake system. An EGR valve 7 is installed in the exhaust gas recirculation system, and an oxidation catalyst 10 and a particulate filter 11 are arranged in the exhaust gas post-treatment system; after the electronic controller 16 collects the position information of the accelerator pedal 5, it calculates the position of each cylinder according to the driver's request. The amount of air introduced into the combustion chamber 2 and the amount of fuel injected. The fresh air is supercharged by the variable cross-section supercharger 9, mixed with part of the exhaust gas flowing through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com