Multifunctional splitting snap-chilling heat exchanger

A quenching heat exchanger, multi-functional technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of increasing equipment cost, reducing equipment utilization, and not being able to simultaneously crack liquid phase raw materials and Gas raw materials and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

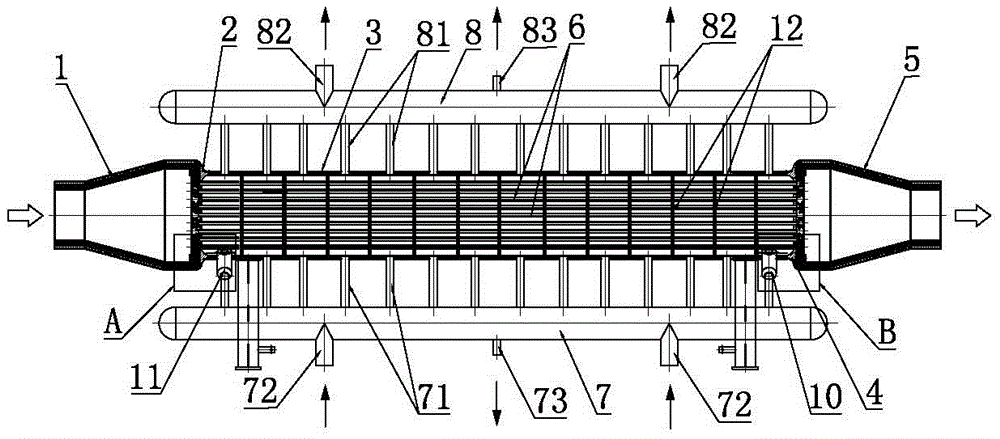

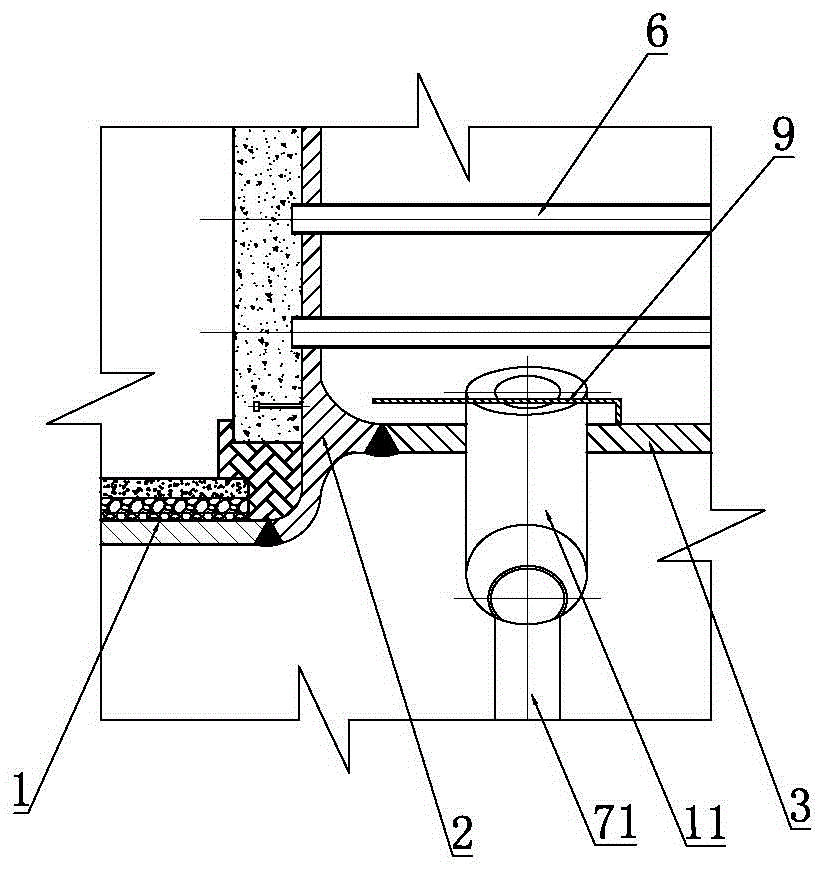

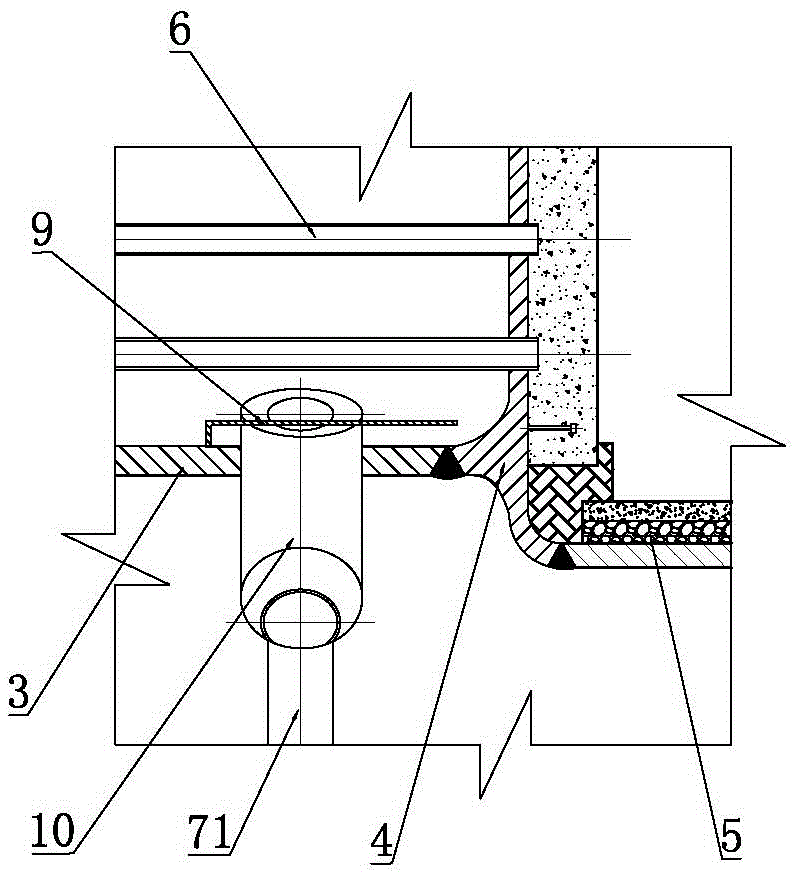

[0036] A kind of multifunctional pyrolysis quenching heat exchanger of the present embodiment, as figure 1 As shown, its structure includes the inlet tube box 1, the inlet flexible tube plate 2, the shell 3, the outlet flexible tube plate 4 and the outlet tube box 5 connected in sequence, and the shell 3 is built with the inlet tube box 1 and the outlet tube The heat exchange tube 6 of case 5, the cracking raw material enters from the inlet tube box 1 and exchanges heat with the cooling medium in the heat exchange tube 6 and the housing 3, and then flows out through the outlet tube box 5 (such as figure 1 indicated by the middle arrow), where the cracking raw materials include high-temperature liquid-phase raw materials or high-temperature gas raw materials.

[0037] Such as figure 1 As shown, the quench heat exchanger also includes a downcomer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com