Blasting method and device of axial progressive secondary high-efficiency blasting device

A secondary blasting and progressive technology, applied in the field of blasting, to achieve the effect of increasing utilization rate, reducing blasting vibration, and reducing the unit consumption of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

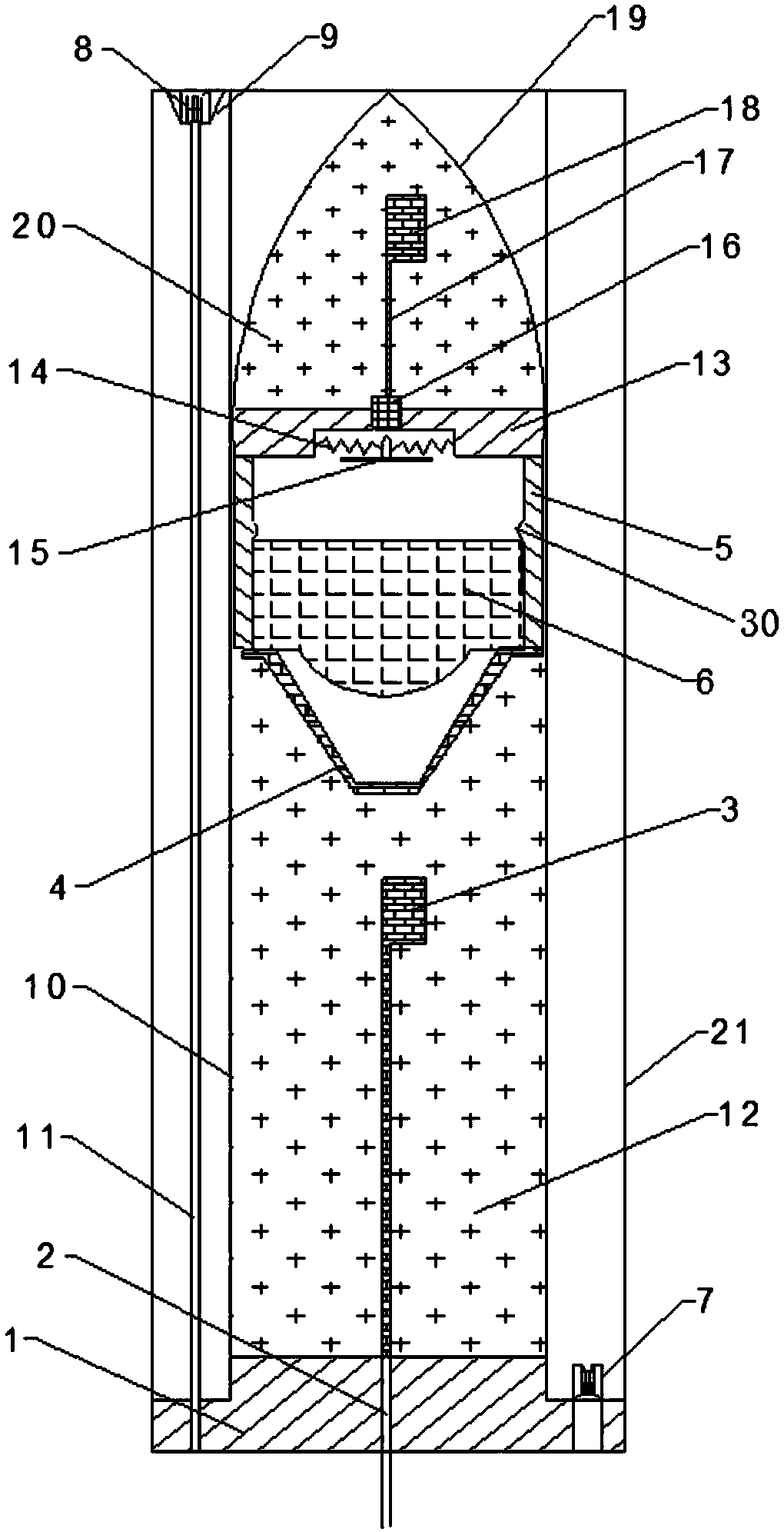

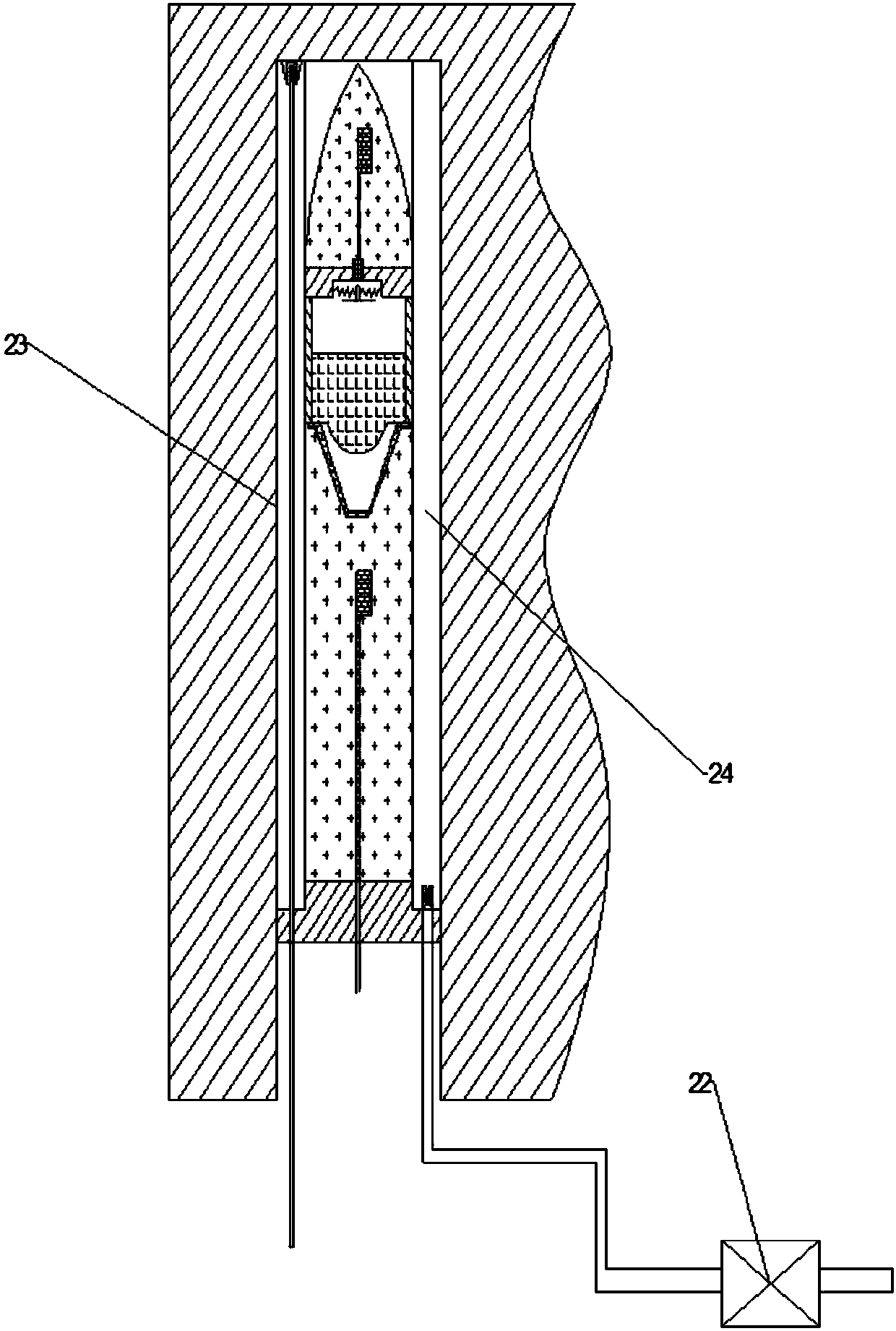

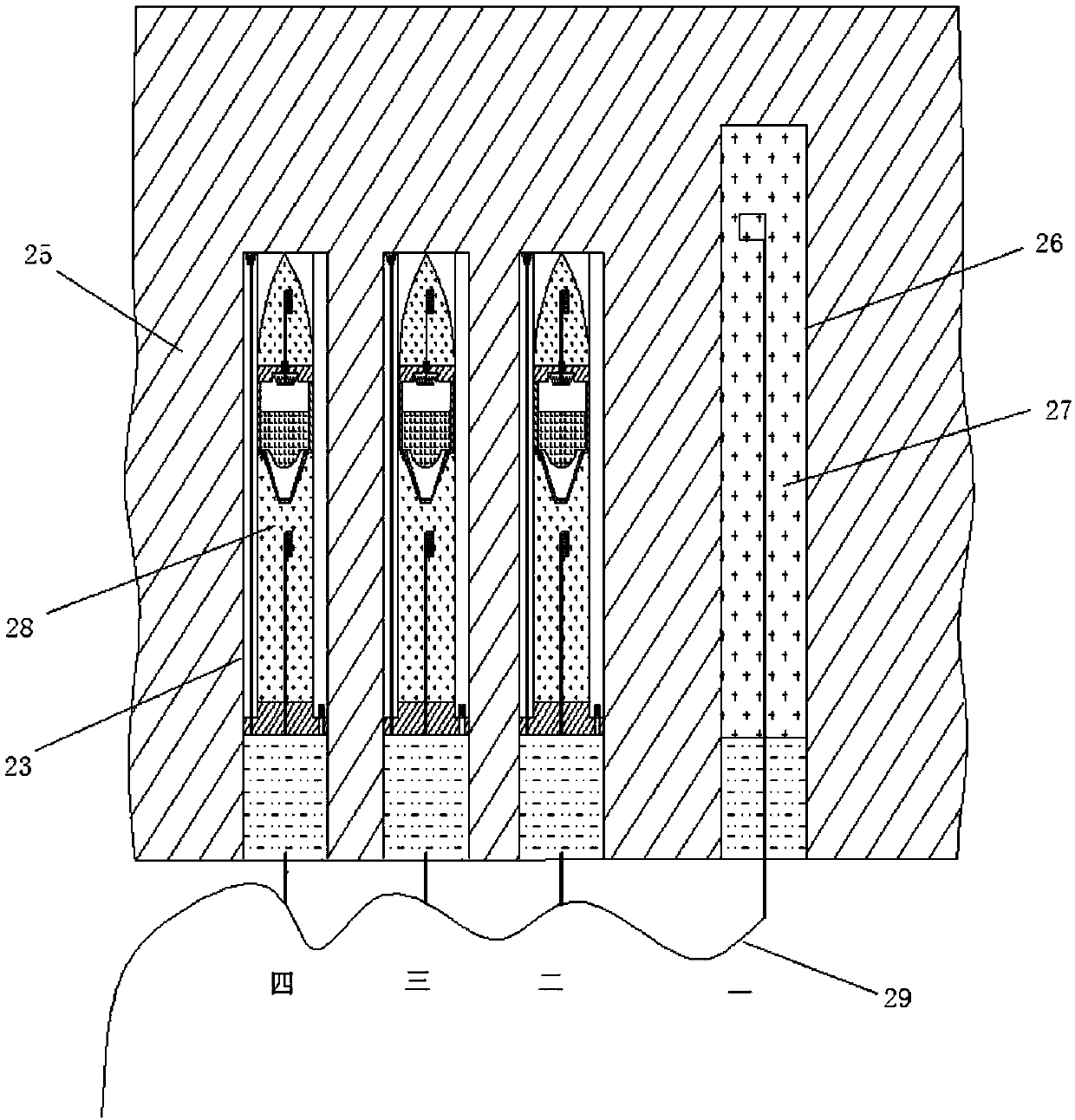

[0017] Embodiment of the present invention: a blasting method of an axial progressive secondary high-efficiency blasting device. The method is to install the blasting cylinder in the auxiliary blast hole and isolate the auxiliary blast hole from the outside air, and set The first-level blasting main body and the second-level blasting main body, the first-level blasting main body conducts an initial explosion, causing cracks in the rock mass, rock loosening, etc., and the first-level blasting main body produces a huge energy-gathering shock wave and pushes the second-level blasting main body to drill deeper In the rock body, under the effect of the time-delayed explosive located in the main body of the secondary blasting, a secondary progressive blasting with a slight delay is produced.

[0018] The specific method to realize the isolation in the auxiliary blast hole after installing the blasting cylinder is that the blasting cylinder is made of plastic material, and its two sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com