Microalgae flotation efficiency predicting device and method based on microalgae surface characteristics

A technology for predicting device and surface characteristics, applied in the field of microalgae flotation efficiency prediction device based on microalgae surface characteristics, can solve the problem of inability to accurately and reliably predict microalgae flotation efficiency, and inability to obtain flotation efficiency microalgae surface free energy etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

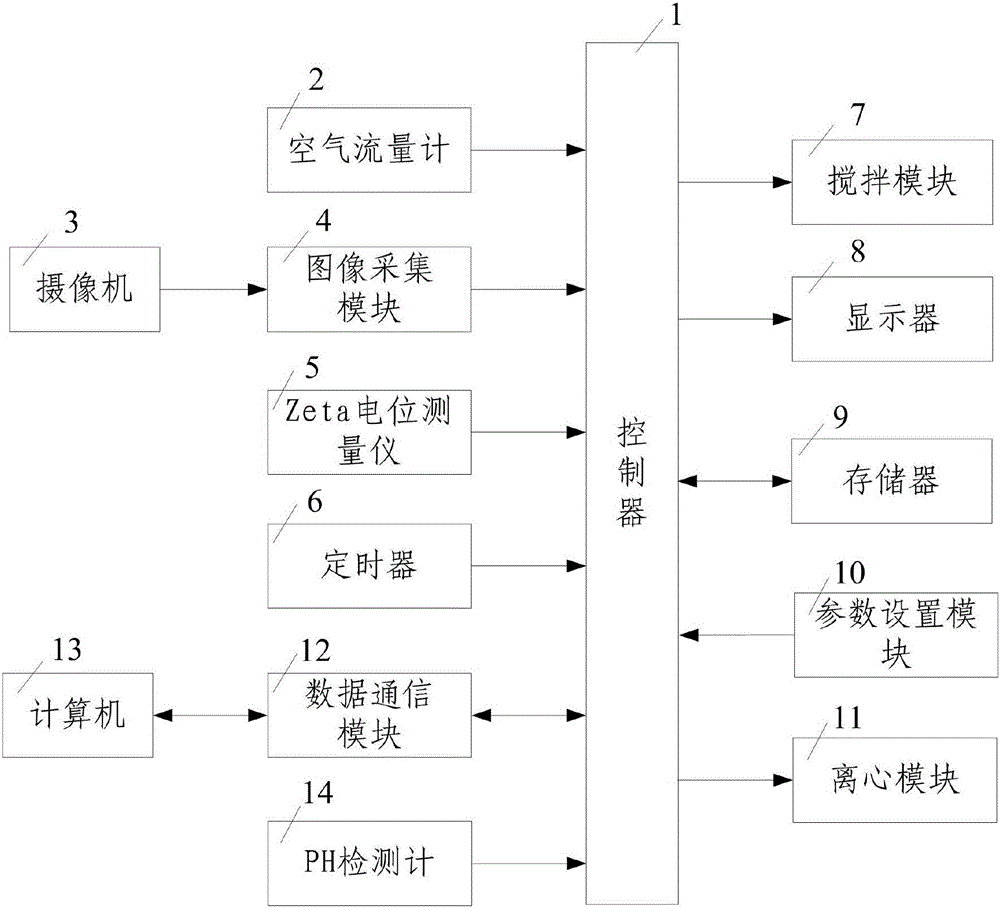

[0060] This embodiment includes a controller 1, a contact angle detection module and a Zeta potential measuring instrument 5 that detects the Zeta potential of microalgae, and a data processing device connected to the controller 1, the input terminal of the controller 1 is connected with air Flowmeter 2, PH detector 14 and timer 6, the output terminal of described controller 1 is connected with stirring module 7, centrifugal module 11 and display 8, and described contact angle detection module comprises camera 3 and is connected with camera 3 output terminals The connected image acquisition module 4, the image acquisition module 4 is connected with the controller 1.

[0061] In this embodiment, a memory 9 and a parameter setting module 10 are also included, and both the memory 9 and the parameter setting module 10 are connected to the controller 1 .

[0062] In this embodiment, by setting the parameter setting module 10, the aeration flow rate, stirring time, centrifugation ti...

Embodiment 2

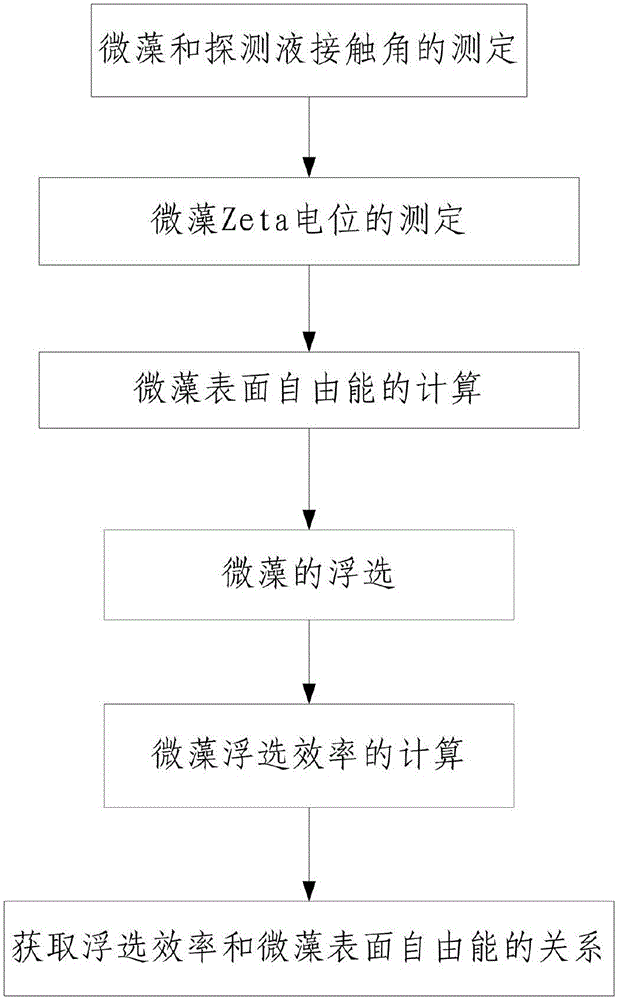

[0068] This embodiment includes the following steps:

[0069] Step 1, the measurement of microalgae and detection fluid contact angle, the process is as follows:

[0070]Step 101. Washing and pH adjustment of the microalgae liquid: wash the microalgae liquid twice with deionized water, then add HCL solution or NaOH solution to the washed microalgae liquid, and use a pH detector for 14 pairs of washed microalgae liquids. The pH value of the algae liquid is detected in real time and the detected pH value of the washed microalgae liquid is sent to the controller 1, so that the pH value of the washed microalgae liquid is 5-10, and the microalgae liquid to be treated is obtained;

[0071] In this embodiment, the rotational speed of the centrifugal treatment in step 101 is 2500 rpm, and in actual use, the rotational speed of the centrifugal treatment can be adjusted within the range of 2500 rpm to 3000 rpm according to specific requirements. The time of centrifugation is 5 minutes,...

Embodiment 3

[0110] In this embodiment, the difference from Example 2 is: in this embodiment, the microalgae liquid is Anabaena liquid, the rotating speed of centrifugation in step 101 is 3000rpm, the time of centrifugation is 10min, and the test tube in step 201 Leave standstill 15min, the time that stirring module 7 stirs in the step 5 is 4min, the addition of flotation agent cetyltrimethylammonium bromide is 55mg / L, and the rotating speed of described flotation cell is 1000rpm, and described flotation The air flow rate of the selection tank is 200L / h, and the flotation time is 15min. In this embodiment, the remaining steps and process parameters are the same as those in Embodiment 2.

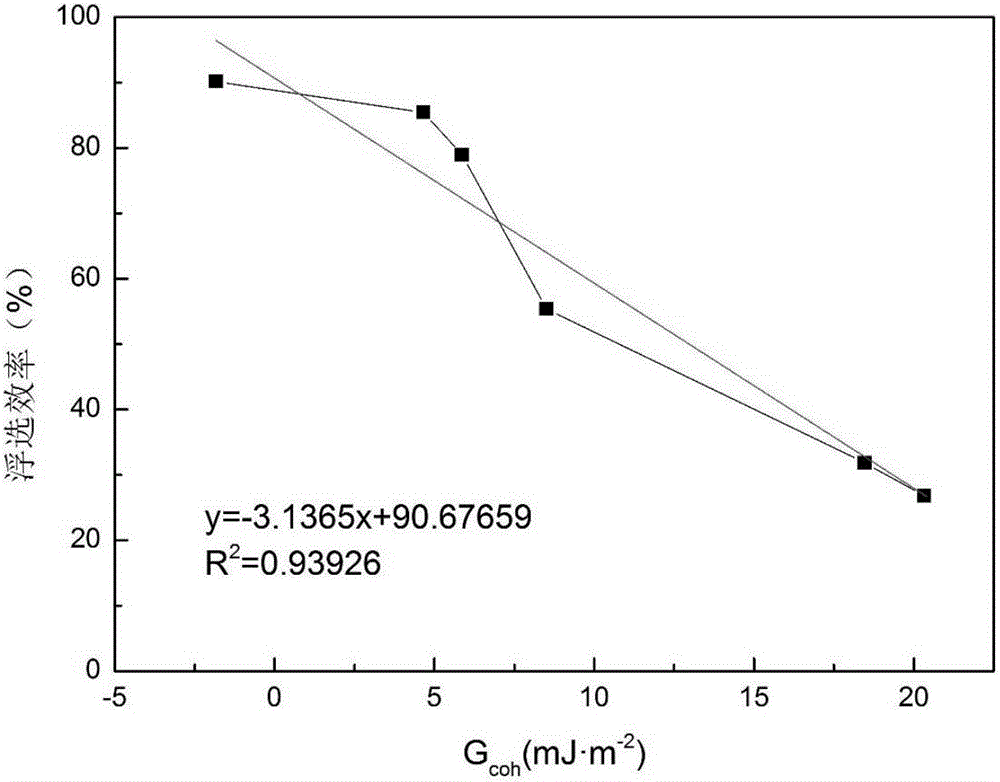

[0111] In this example, the surface free energy ΔG of Anabaena was obtained cohi and flotation efficiency W i The relationship between the curve and the expression, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com