Manufacturing method for AlAs/Ge/AlAs structure-based plasma pin diode used in multilayered holographic antenna

An alas-ge-alas, manufacturing method technology, applied in the direction of antenna, loop antenna, radiating element structure, etc., can solve the problems of large injection dose and energy, low integration, incompatibility, etc., to improve the breakdown voltage, The effect of improving device performance and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

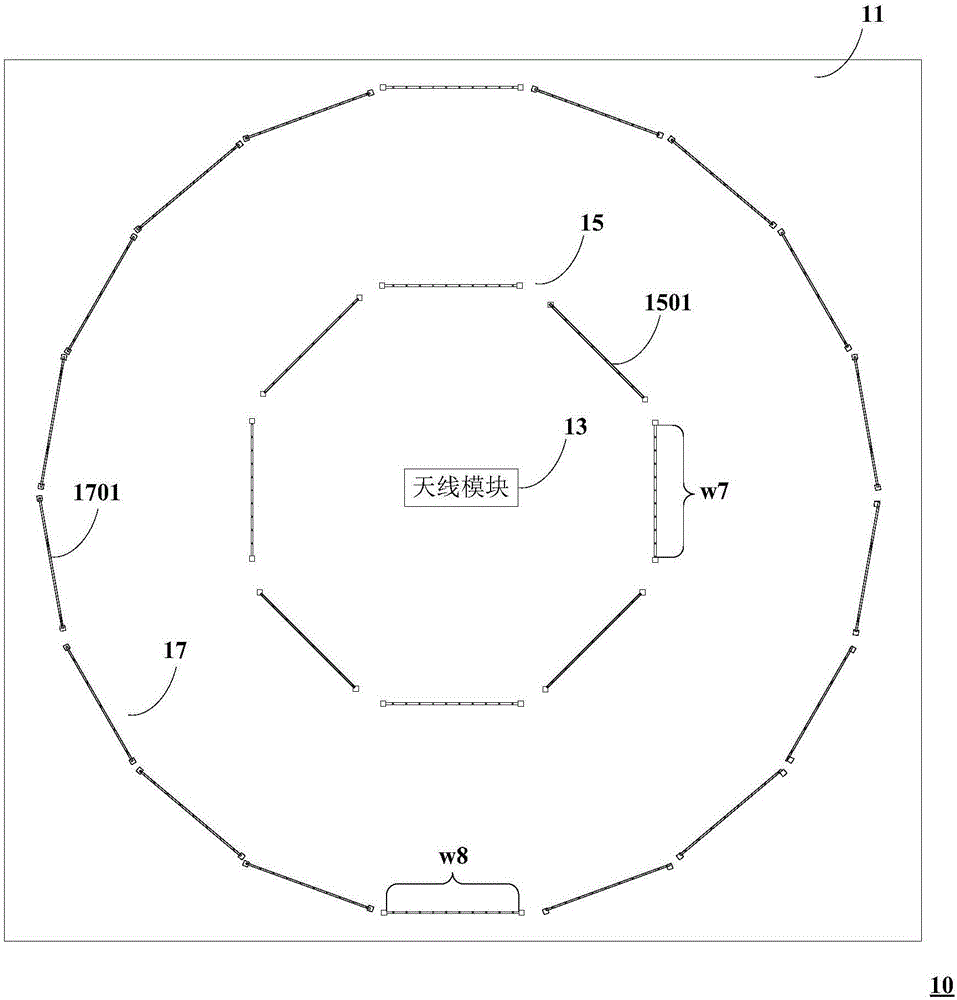

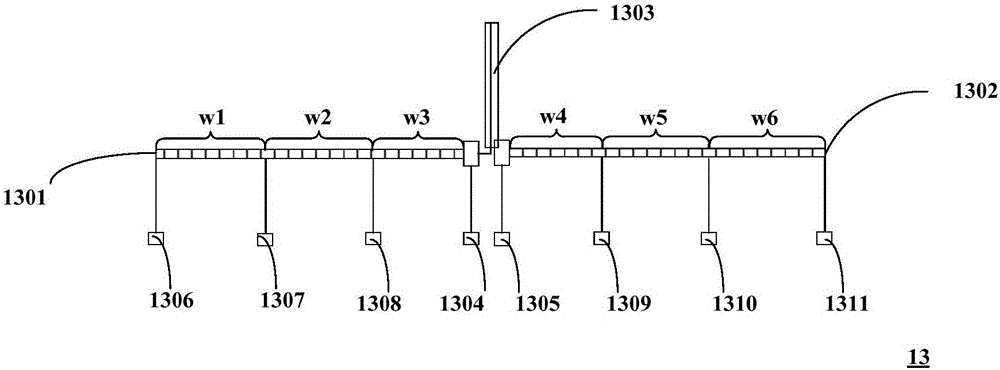

[0064] An embodiment of the present invention provides a method for manufacturing an AlAs-Ge-AlAs structure-based plasmonic pin diode in a multilayer holographic antenna. The pin diode is used to prepare the holographic antenna. Please refer to figure 1 , figure 1 A structural diagram of a reconfigurable multi-layer holographic antenna provided by an embodiment of the present invention; the holographic antenna includes: a semiconductor substrate (11), an antenna module (13), a first holographic ring (15) and a second A holographic ring (17); the antenna module (13), the first holographic ring (15) and the second holographic ring (17) are all manufactured on the semiconductor substrate (11) using a semiconductor process above; wherein, the antenna module (13), the first holographic ring (15) and the second holographic ring (17) all include pin diode strings connected in series;

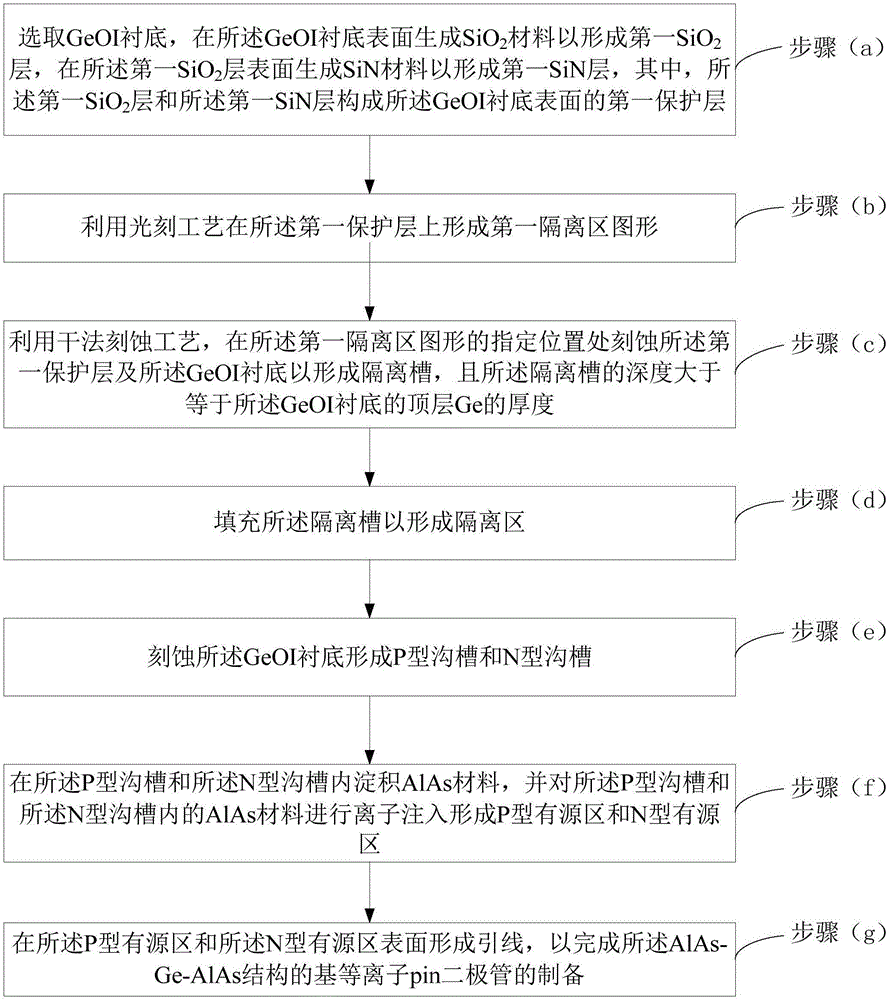

[0065] Please refer to figure 2 , figure 2 It is a schematic diagram of the manufacturing meth...

Embodiment 2

[0115] See Figure 8a-Figure 8r , Figure 8a-Figure 8r A schematic diagram of a method for manufacturing an AlAs-Ge-AlAs structure-based plasmonic pin diode in another multilayer holographic antenna provided by the embodiment of the present invention. The AlAs-Ge-AlAs structure-based plasmonic pin diode with a length of 100 microns) is described in detail as an example, and the specific steps are as follows:

[0116] Step 1, substrate material preparation steps:

[0117] (1a) if Figure 8a As shown, the (100) crystal orientation is selected, the doping type is p-type, and the doping concentration is 10 14 cm -3 A GeOI substrate sheet 101, the thickness of the top layer Ge is 50 μm;

[0118] (1b) if Figure 8b As shown, the method of chemical vapor deposition (Chemical vapor deposition, referred to as CVD) is used to deposit a layer of the first SiO with a thickness of 40nm on the GeOI substrate. 2 layer 201;

[0119] (1c) Deposit a layer of first Si with a thickness of...

Embodiment 3

[0146] Please refer to Figure 9 , Figure 9 A schematic structural diagram of an AlAs-Ge-AlAs structure-based plasmonic pin diode in another multilayer holographic antenna provided by an embodiment of the present invention. The AlAs-Ge-AlAs structure-based plasmonic pin diode adopts the above-mentioned as figure 2 The manufacturing method shown is made, specifically, the base plasma pin diode of the AlAs-Ge-AlAs structure is prepared and formed on the GeOI substrate 301, and the P region 304, the N region 305 of the pin diode and the lateral position of the P region 304 The I region between the N region 305 is located in the top Ge layer 302 of the GeOI substrate. Wherein, the pin diode can be isolated by STI deep trenches, that is, an isolation trench 303 is provided outside the P region 304 and the N region 305 , and the depth of the isolation trench 303 is greater than or equal to the thickness of the top Ge layer 302 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com