Copper-doped perovskite thin film, in-situ preparation method and hole-transport-layer-free solar cell device

An in-situ preparation and perovskite technology, which is applied in the direction of electrical solid devices, electrical components, semiconductor devices, etc., can solve the problems of high cost, high cost of hole transport layer, low photoelectric conversion efficiency of perovskite solar cells, etc. , to achieve the effect of reducing energy consumption, reducing cost, and the preparation method is simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Substrate cleaning: Clean the ITO glass ultrasonically with detergent for 30 minutes, then rinse it with deionized water, then ultrasonically clean it with acetone for 30 minutes, then ultrasonically clean it with absolute ethanol for 30 minutes, and finally dry it with a nitrogen gun and use ultraviolet light to clean it. Irradiate for 2 minutes;

[0053] (2) Cuprous iodide: Use vacuum evaporation technology to vapor-deposit a 10nm-thick elemental copper film on the cleaned ITO conductive glass, then add elemental iodine particles in a closed container, and then deposit the ITO conductive glass with a copper film Put it in and keep it at 25°C for 1-5min until the copper reacts completely;

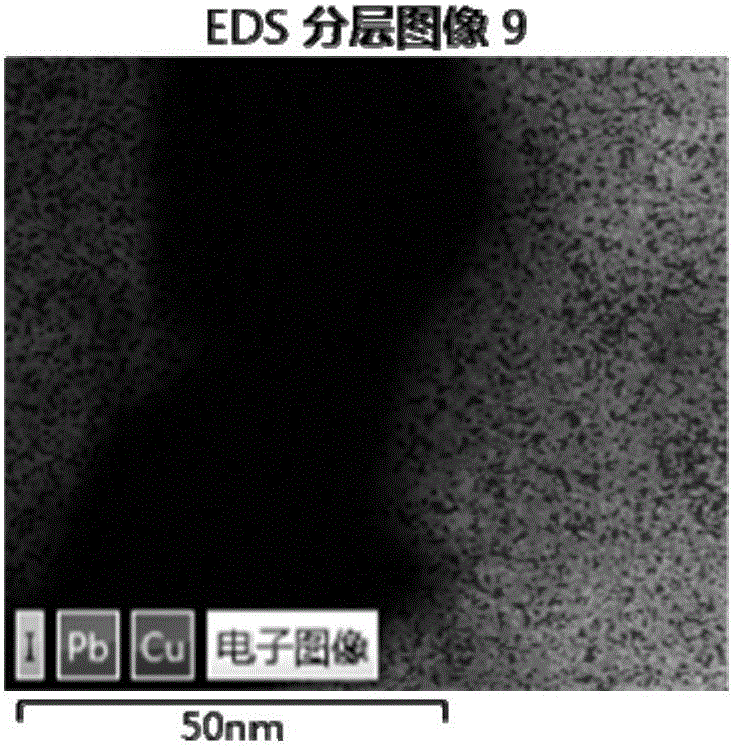

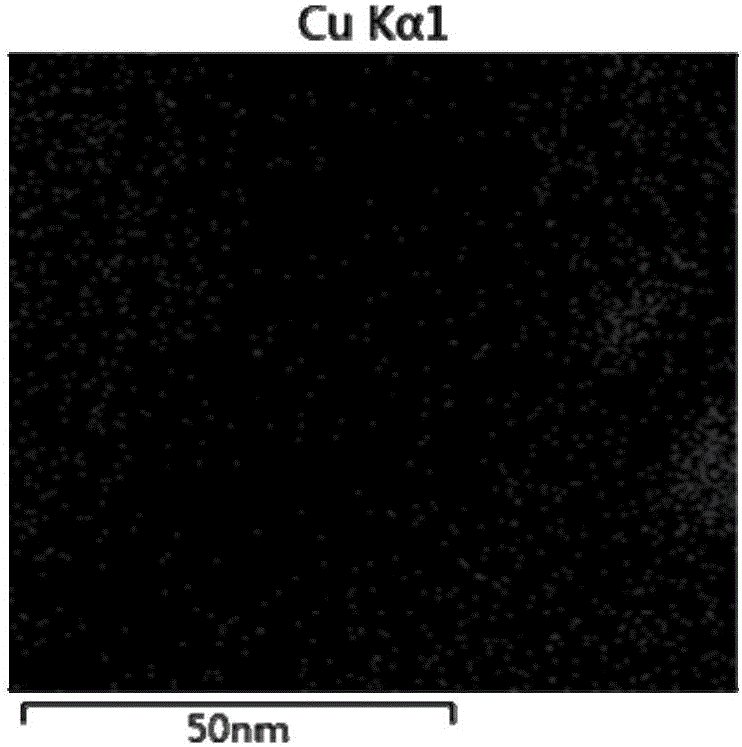

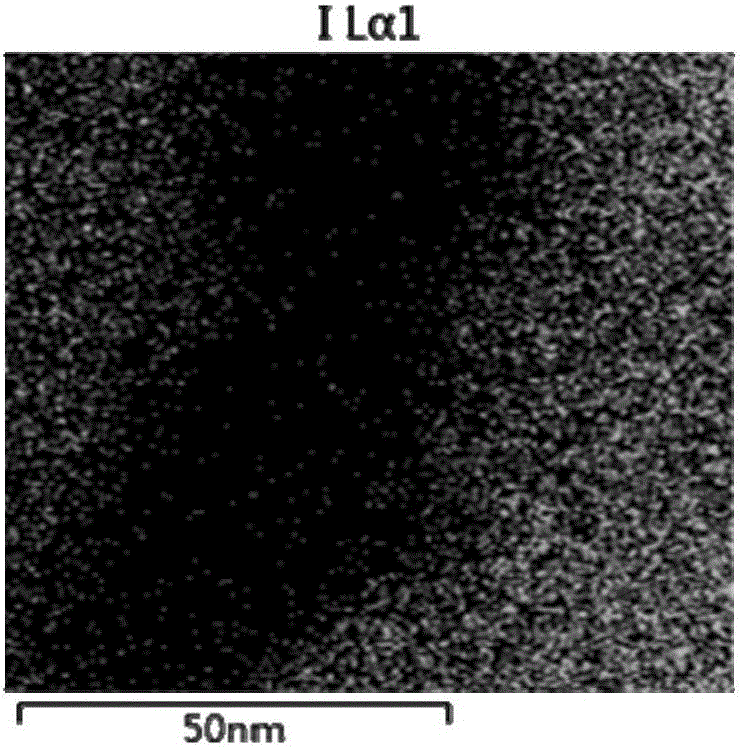

[0054] (3) Copper-doped perovskite layer: Under oxygen-barrier and anhydrous conditions such as a glove box, take lead acetate and CH with a molar ratio of 1:3 3 NH 3 I was dissolved in N,N-dimethylformamide to prepare 1mol / L CH 3 NH 3 PB 3 solution, the CH 3 NH 3 PB 3 T...

Embodiment 2

[0057] (1) Substrate cleaning: Clean the ITO glass ultrasonically with detergent for 30 minutes, then rinse it with deionized water, then ultrasonically clean it with acetone for 30 minutes, then ultrasonically clean it with absolute ethanol for 30 minutes, and finally dry it with a nitrogen gun and use ultraviolet light to clean it. Irradiate for 2 minutes;

[0058] (2) Cuprous iodide: Use vacuum evaporation technology to vapor-deposit a 20nm-thick elemental copper film on the cleaned ITO conductive glass, add elemental iodine particles into the airtight container, and then conduct the ITO of the deposited copper film Put the glass in and keep it at 25°C for 1-5min until the copper reacts completely;

[0059] (3) Copper-doped perovskite layer: under the condition of oxygen barrier and anhydrous, take lead acetate and CH with a molar ratio of 1:3 3 NH 3 I was dissolved in N,N-dimethylformamide to prepare 1mol / L CH 3 NH 3 PB 3 solution, the CH 3 NH 3 PB 3 The solution w...

Embodiment 3

[0062] (1) Substrate cleaning: Clean the ITO glass ultrasonically with detergent for 30 minutes, then rinse it with deionized water, then ultrasonically clean it with acetone for 30 minutes, then ultrasonically clean it with absolute ethanol for 30 minutes, and finally dry it with a nitrogen gun and use ultraviolet light to clean it. Irradiate for 2 minutes;

[0063] (2) Cuprous iodide: Use vacuum evaporation technology to vapor-deposit a 30nm-thick elemental copper film on the cleaned ITO conductive glass, add elemental iodine particles into the airtight container, and then conduct the ITO of the deposited copper film Put the glass in and keep it at 25°C for 1-5min until the copper reacts completely;

[0064] (3) Copper-doped perovskite layer: under the condition of oxygen barrier and anhydrous, take lead acetate and CH with a molar ratio of 1:3 3 NH 3 I was dissolved in N,N-dimethylformamide to prepare 1mol / L CH 3 NH 3 PB 3 solution, the CH 3 NH 3 PB 3 The solution w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com