Method for improving photoelectric conversion efficiency and light-heat stability of organic solar device

A technology of photoelectric conversion efficiency and organic solar energy, which is applied in photovoltaic power generation, electric solid-state devices, semiconductor devices, etc., can solve the problems of small insulating molecules affecting device performance, improve photoelectric conversion efficiency and photothermal stability, and improve phase separation , Increase the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

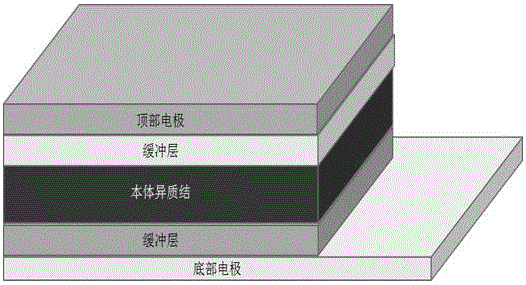

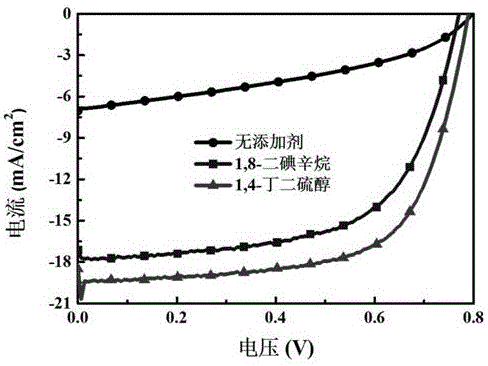

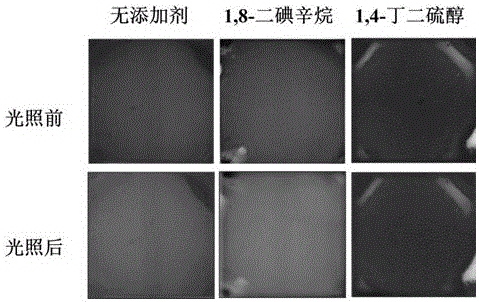

[0021] This embodiment is based on the light absorbing layer being PTB7-Th:PC 71 Adding 1,4-butanedithiol with a boiling point of 196 °C as a solvent additive to the BM reverse solar cell, compared with the traditional additive DIO, can improve its device performance and photostability. The specific steps are as follows.

[0022] (1) Cleaning of the cathode ITO glass: The ITO glass is ultrasonically cleaned twice with acetone, once with detergent, and three times with deionized water, each cleaning time is more than 15 minutes, and then dried by plasma for 3 minutes.

[0023] (2) Preparation of cathode buffer layer: spin-coat ZnO precursor solution on the ITO cathode surface cleaned in step (1), and sinter on a hot stage at about 200 °C to obtain a ZnO film with a thickness of about 40 nm.

[0024] (3) Preparation of the active layer: Spin-coat the light-absorbing layer solution on the ZnO film that has undergone the above operations at a rotation speed of 800 rpm for 1 minute...

Embodiment 2

[0029] This embodiment is based on the light absorbing layer being PTB7-Th:PC 71 Adding 1,3-propanedithiol with a boiling point of 169 °C as a solvent additive to the BM reverse solar cell, compared with the traditional additive DIO, can improve its device performance and thermal stability. The specific steps are as follows.

[0030] (1) Cleaning of cathode ITO glass: ITO glass is ultrasonically cleaned twice with acetone, once with detergent, and three times with deionized water, each cleaning time is more than 15 minutes, and then dried and treated with ultraviolet light for 10 minutes.

[0031] (2) Preparation of cathode buffer layer: spin-coat ZnO precursor solution on the ITO cathode surface cleaned in step (1), and sinter on a hot stage at about 220 °C to obtain a ZnO film with a thickness of about 40 nm.

[0032] (3) Preparation of the active layer: Spin-coat the light-absorbing layer solution on the ZnO film that has undergone the above operations at a rotation speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com