Special-shaped battery aluminum-plastic film automatic adhesive-coating production line and adhesive-coating process thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] The present invention will be further described below in conjunction with accompanying drawing:

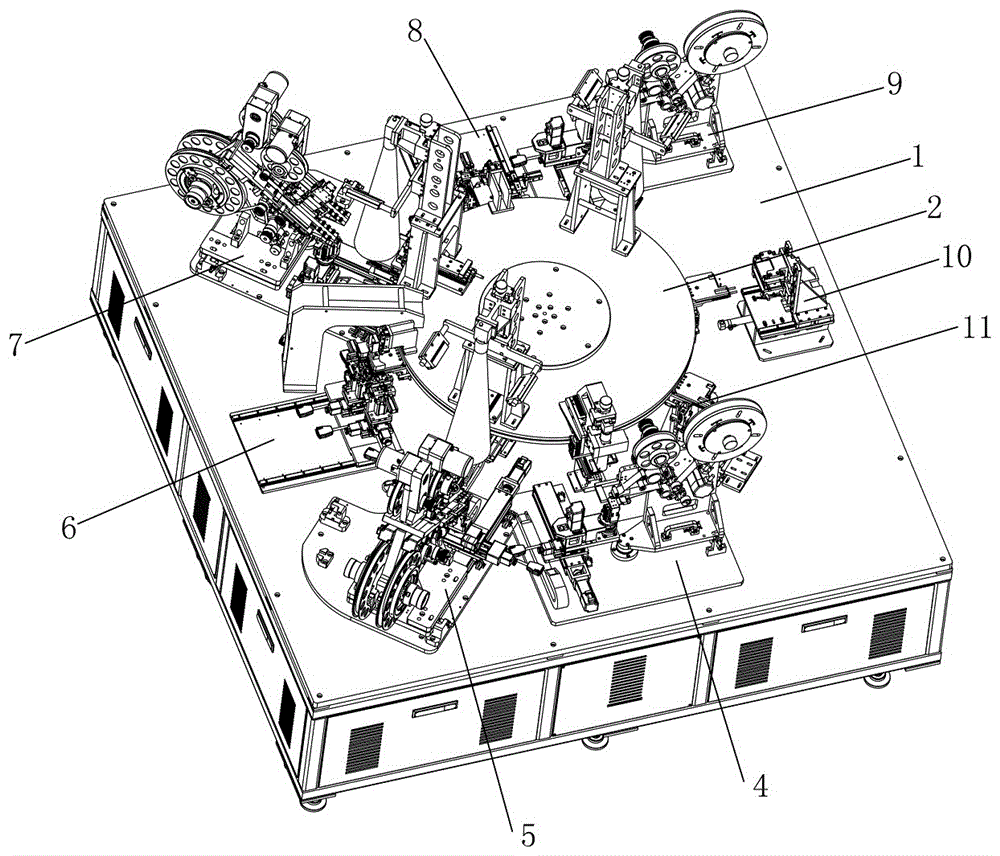

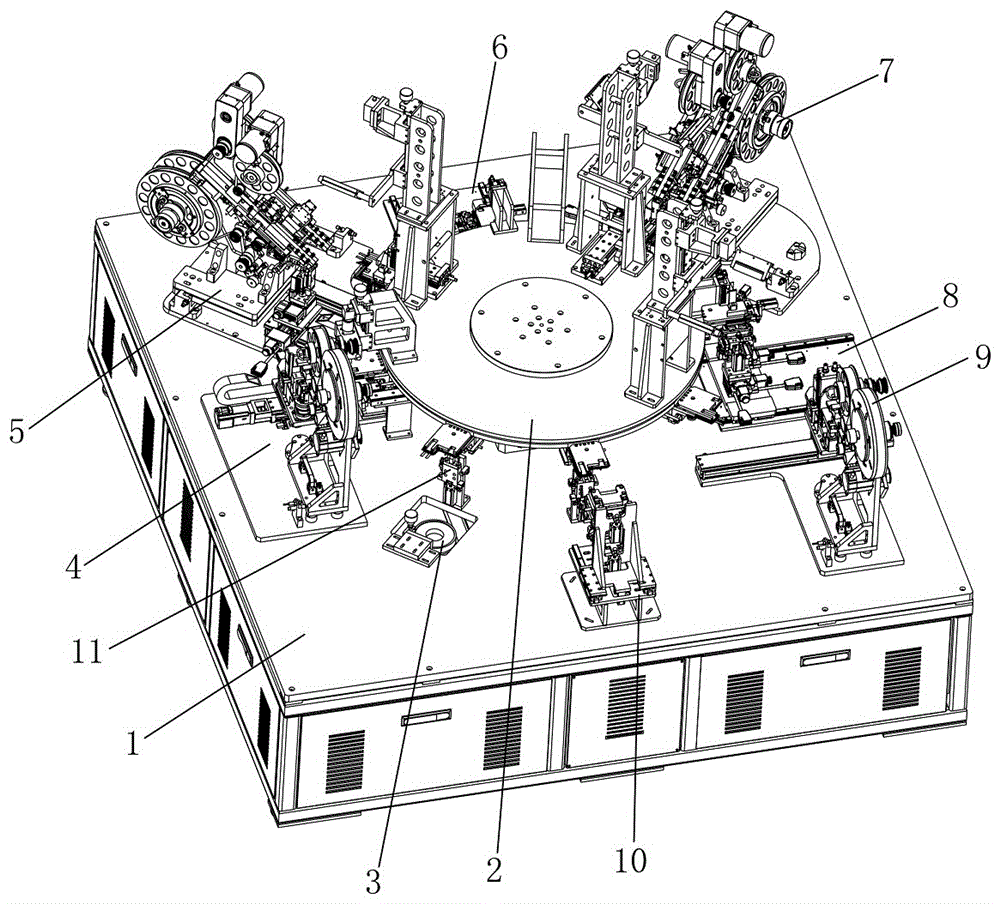

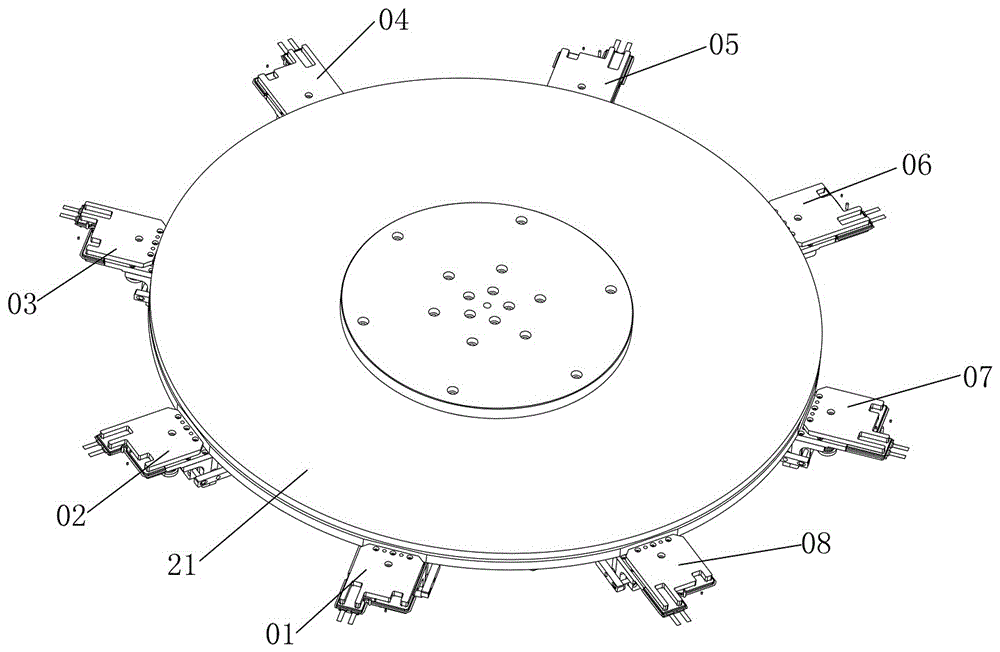

[0112] Such as Figure 1 to Figure 39 As shown, the technical scheme adopted by the present invention is as follows: an automatic gluing production line for aluminum-plastic film of special-shaped batteries, including a frame 1, a gluing platform 2, a front disc gluing mechanism 4, a first gluing mechanism 5, a first Encapsulating mechanism 6, second gluing mechanism 7, second encapsulating mechanism 8, reverse-side disc adhesive mechanism 9 and hot pressing mechanism 10, wherein the above-mentioned encapsulating platform 2 is rotatably arranged on the frame 2, and includes The outer edge of the glue platform 2 is sequentially provided with a loading and unloading station 01, a front wafer glue station 02, a first glue station 03, a first glue wrapping station 04, a second glue station 05, The second gluing station 06, the reverse side disc gluing station 07 and the hot pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com