Preparation method of CuMn2O4/CNT (carbon nano tube) composite electrocatalyst

An electrocatalyst and conductive agent technology, applied in circuits, electrical components, battery electrodes, etc., to achieve the effects of improved electrochemical stability, easy implementation, and mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

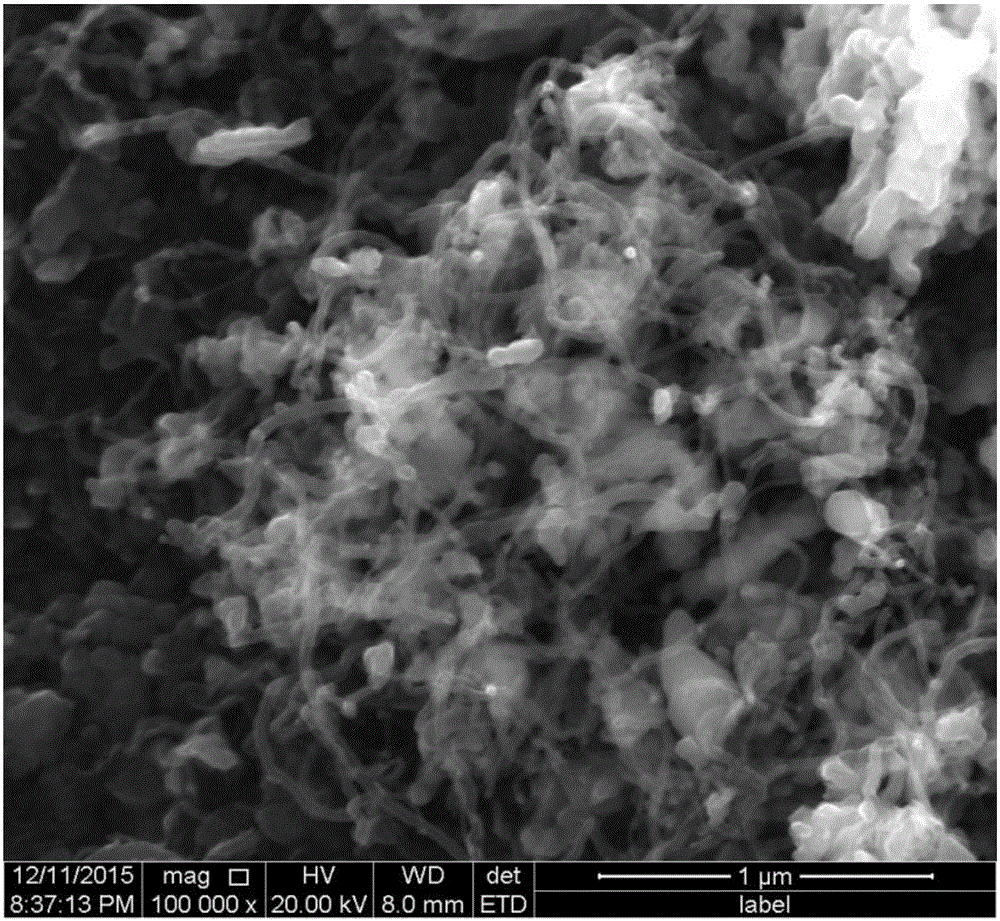

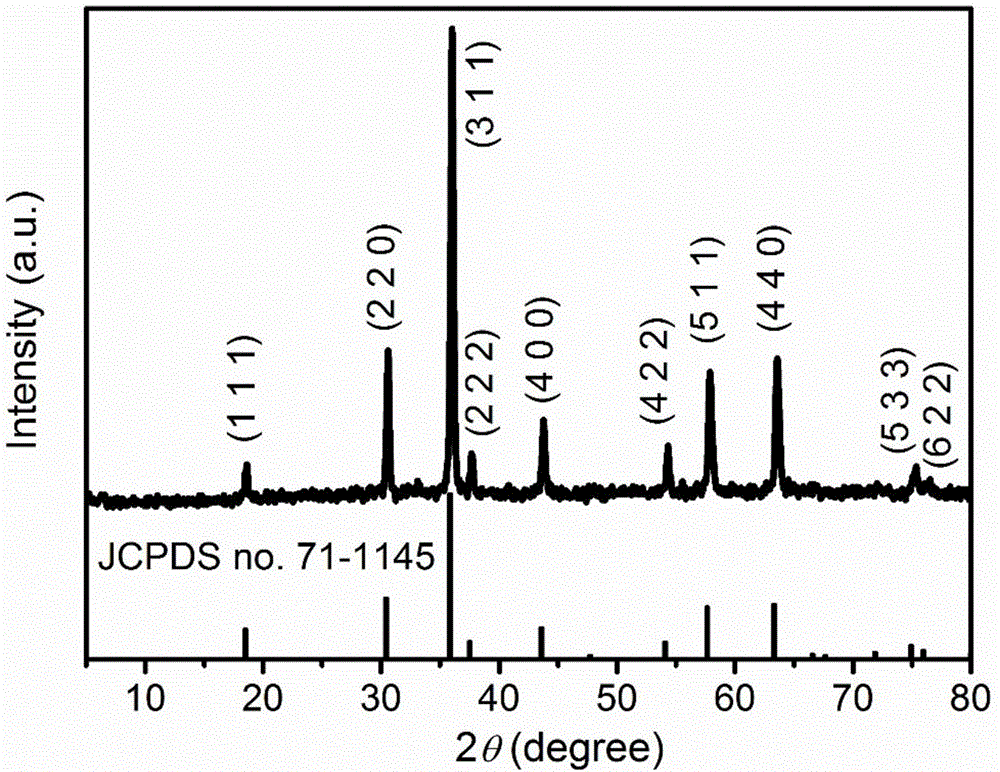

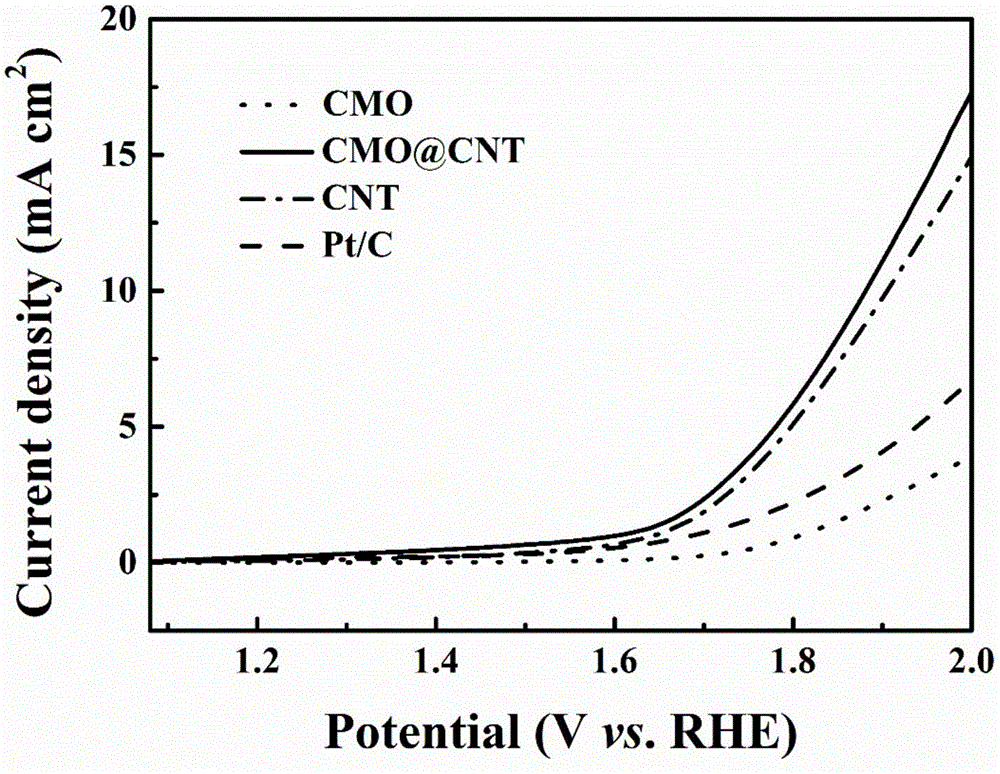

[0025] 1), weigh 3.14g Cu(NO 3 ) 2 ·3H 2 O, 4.27g Mn(NO 3 ) 2 4H 2 O and 10g glycine, add 500mL deionized water, stir until completely dissolved, and obtain solution A. Weigh 10g of citric acid and set aside. Put solution A in a water bath at 80°C, then add citric acid to the solution in batches while stirring, and finish adding within about 1 hour. Continue to stir until it forms a gel. Put the formed wet gel into an oven at 250° C., and dry it for 1 hour to obtain a dry gel. Grind the obtained xerogel and put it into a muffle furnace for calcination for 5 hours to obtain CuMn with spinel structure 2 o 4 .

[0026] 2), the prepared CuMn in step 1 2 o 4 Mix with conductive agent CNT, the two components 100mg according to a certain ratio (80% CuMn 2 o 4 : 20% CNT) was dissolved in 100ml ethanol, ultrasonically dispersed for 10min, then dispersed twice with cell crushing (power 1100W), centrifuged at low speed (4500rpm), washed with water for many times, vacuum dri...

Embodiment 2

[0032] 1), weigh 3.14g Cu(NO 3 ) 2 ·3H 2 O, 4.27g Mn(NO 3 ) 2 4H 2 O and 10g glycine, add 500mL deionized water, stir until completely dissolved, and obtain solution A. Weigh 10g of citric acid and set aside. Put solution A in a water bath at 80°C, then add citric acid to the solution in batches while stirring, and finish adding within about 1 hour. Continue to stir until it forms a gel. Put the formed wet gel into an oven at 250° C., and dry it for 1 hour to obtain a dry gel. Grind the obtained xerogel and put it into a muffle furnace for calcination for 5 hours to obtain CuMn with spinel structure 2 o 4 .

[0033] 2), the prepared CuMn in step 1 2 o 4 Mix with conductive agent CNT, the two components 100mg according to a certain ratio (80% CuMn 2 o 4 : 20% CNT) was dissolved in 100ml ethanol, ultrasonically dispersed for 10min, then dispersed twice with cell crushing (power 1100W), centrifuged at low speed (4500rpm), washed with water several times, and vacuum-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com