Whitened red phosphorus, low-odor and low-emission whitened red phosphorus flame retardation master batch for nylon, and preparation method of master batch

A flame-retardant masterbatch and low-emission technology, applied in the field of polymer materials, can solve the problems of easy moisture absorption, easy oxidation and deterioration, oxidation of phosphoric acid, etc., and achieve the effect of reducing TVOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

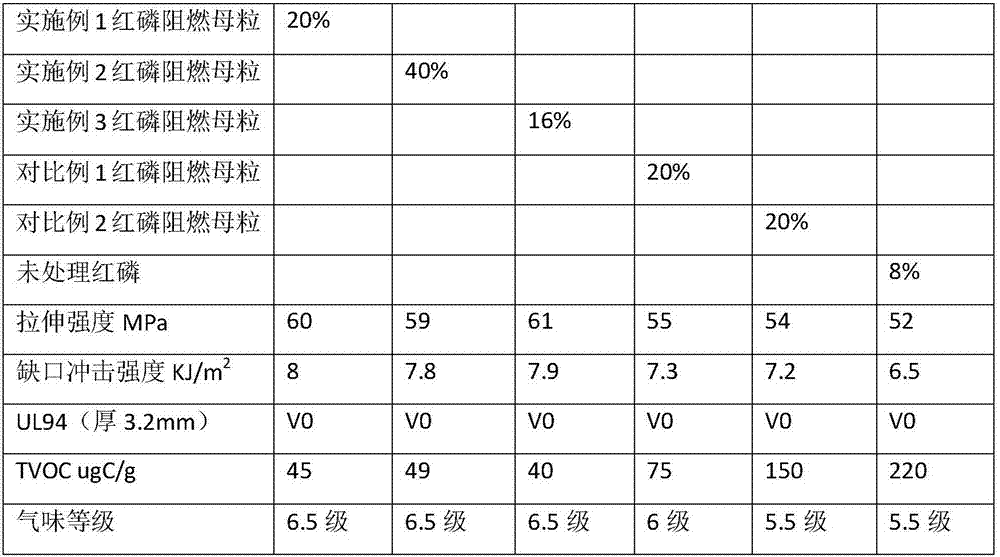

Examples

specific Embodiment approach

[0025] Below by the description of specific embodiment, the present invention is further described, and whiteness red phosphorus used in each embodiment below and odor adsorption masterbatch are all prepared by following method:

[0026] Preparation of whitened red phosphorus: 30% red phosphorus, 10% aluminum sulfate, 5% urea, 50% water, 5% oil-soluble phenolic resin. Aluminum hydroxide coating process: first add aluminum sulfate to water, stir to dissolve it completely, then add red phosphorus, stir for 20 minutes, then transfer to a ball mill to grind until the diameter of red phosphorus particles is 5-10um, and then transfer to reaction In the kettle, slowly add caustic soda (10wt% solution) while stirring until the PH of the system = 5-6, then add coagulant polyacrylamide, stir evenly, keep warm at 75-85°C for 1.5h, and finally pass Filter, wash, and dry to obtain aluminum hydroxide-coated red phosphorus. Phenolic resin coating process: first dilute the oil-soluble phenol...

Embodiment 1

[0029] Pour 40 parts of whiteness red phosphorus, 55 parts of nylon 6, 3 parts of hydrophobic odor absorption masterbatch, 0.6 part of silane coupling agent, 0.2 part of antioxidant 1098, 0.2 part of antioxidant 168 and 1 part of silicone powder Put it into a high-speed mixer, stir at a high speed, mix until uniform, add it to a twin-screw extruder, melt and extrude, and then granulate to prepare a low-odor, low-emission, whiteness red phosphorus flame-retardant masterbatch for nylon.

[0030] Among them, the temperature of the first zone of the twin-screw extruder is 200°C, the temperature of the second zone is 210°C, the temperature of the third zone is 220°C, the temperature of the fourth zone is 230°C, the temperature of the fifth zone is 240°C, and the temperature of the sixth zone is 250°C; The host speed is 350rpm.

Embodiment 2

[0032] Pour 20 parts of whiteness red phosphorus, 77 parts of nylon 6, 1 part of hydrophobic odor absorption masterbatch, 0.8 part of silane coupling agent, 0.5 part of antioxidant 1098, 0.5 part of antioxidant 168 and 0.2 part of silicone powder Put it into a high-speed mixer, stir at a high speed, mix until uniform, add it to a twin-screw extruder, melt and extrude, and then granulate to prepare a low-odor, low-emission, whiteness red phosphorus flame-retardant masterbatch for nylon.

[0033] Among them, the temperature of the first zone of the twin-screw extruder is 230°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 240°C, the temperature of the fifth zone is 250°C, and the temperature of the sixth zone is 250°C; The host speed is 500rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com