Air-drying water-soluble acrylic resin and preparation method thereof

An acrylic resin, water-soluble technology, applied in the direction of coating, etc., can solve the problems of inability to prepare light-colored paint, easy peeling off of the coating film, and easy yellowing of alkyd resin, so as to promote adhesion stability, improve drying performance, and excellent The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

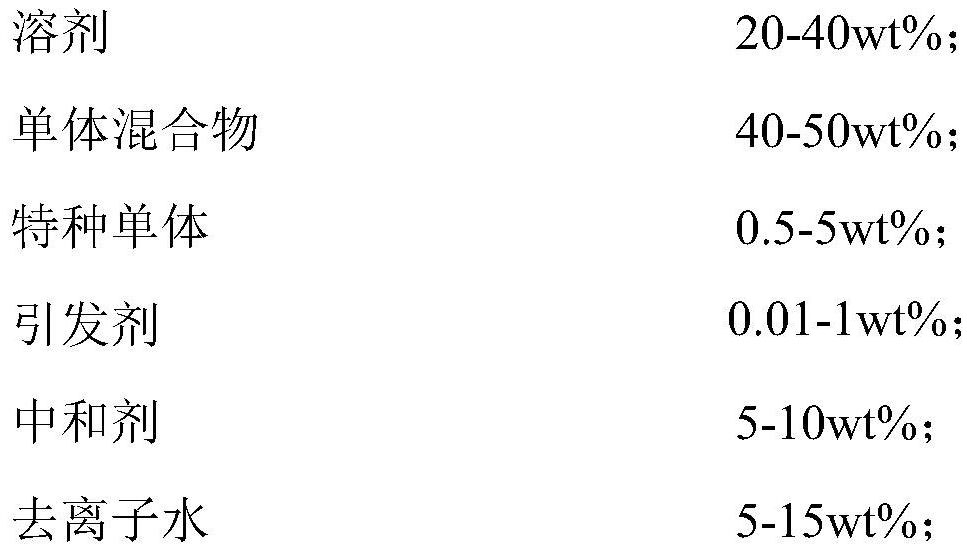

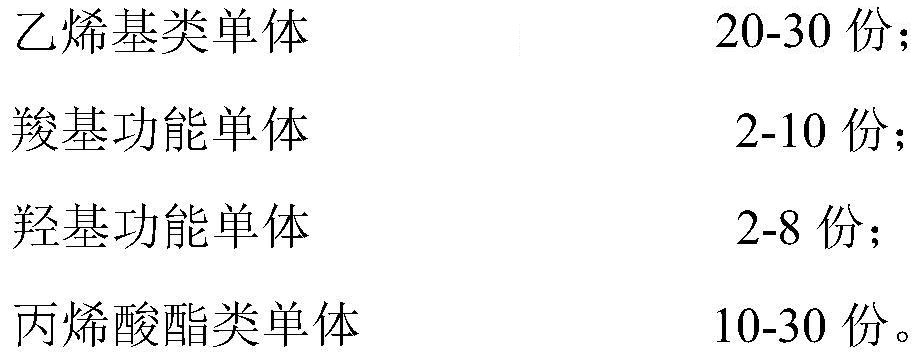

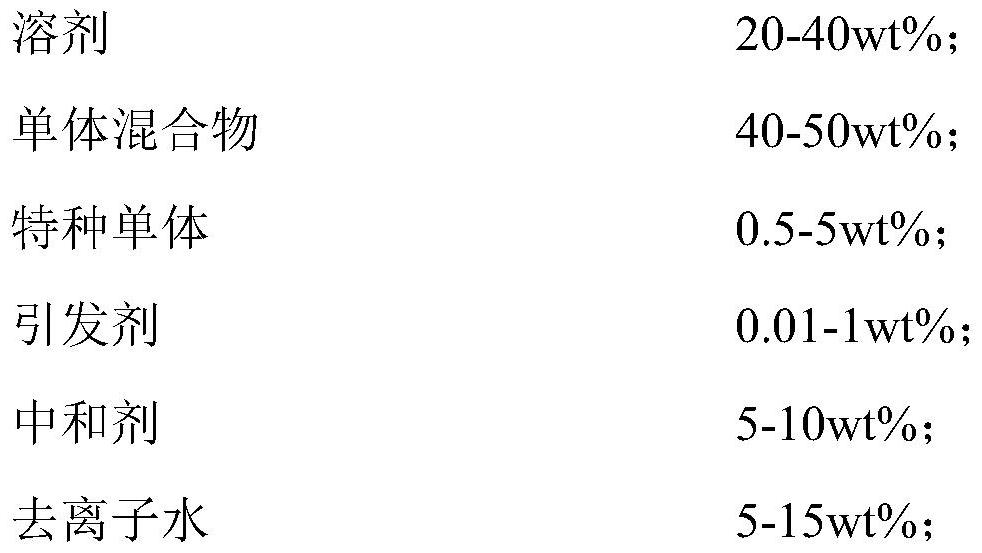

[0063] The second aspect of the present invention provides a method for preparing an air-dried water-soluble acrylic resin as described above, including: adding a monomer mixture, an initiator and a special monomer into a solvent, reacting, adding a neutralizer and deionized water , to obtain the acrylic resin.

[0064] In one embodiment, the preparation method of the air-dried water-soluble acrylic resin of the present invention includes: adding the monomer mixture, the initiator and the special monomer into the solvent for 3-4 hours under the protection of nitrogen, reacting, adding And agent, after mixing, add deionized water to obtain the acrylic resin.

[0065] In order to eliminate residual reactive monomers, additional initiators can be added during the reaction. In one embodiment, the reaction temperature of the present invention is 70-160°C, preferably 80-140°C, more preferably 85-125°C.

[0066]The method of adding monomer mixture, initiator and special monomer in ...

Embodiment 1

[0076] Example 1 also provides the preparation method of the above-mentioned acrylic resin, including: under a nitrogen atmosphere, the temperature of the solvent is raised to 125 ° C, after 3 hours, the monomer mixture is added dropwise, and after the special monomer is diluted with a solvent, 20- 30min, after 1h of heat preservation, add the mixture of initiator and solvent, and heat preservation for 3h again, add neutralizer, after stirring for 30min, add deionized water to obtain light yellow transparent viscous liquid.

Embodiment 2

[0077] Embodiment 2 also provides the preparation method of the above-mentioned acrylic resin, comprising: under a nitrogen atmosphere, the temperature of the solvent is raised to 90° C., 4 / 5 of the monomer mixture is added dropwise in 3 hours, and the remaining 1 / 5 of the monomer mixture and 20g of N-(butoxymethyl)-acrylamide was mixed and added dropwise for 1 hour. After 1 hour of heat preservation, the mixture of initiator and solvent was added, and again heat preservation of 3 hours was added. Neutralizing agent was added and stirred for 30 minutes. Deionized water was added to obtain Light yellow transparent viscous liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com