One-component silane-modified polyether sealant for automobiles and preparation method thereof

A silane-modified polyether, one-component technology, which is applied in the field of sealants, can solve problems such as unfavorable health of passengers and achieve the effect of reducing TVOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

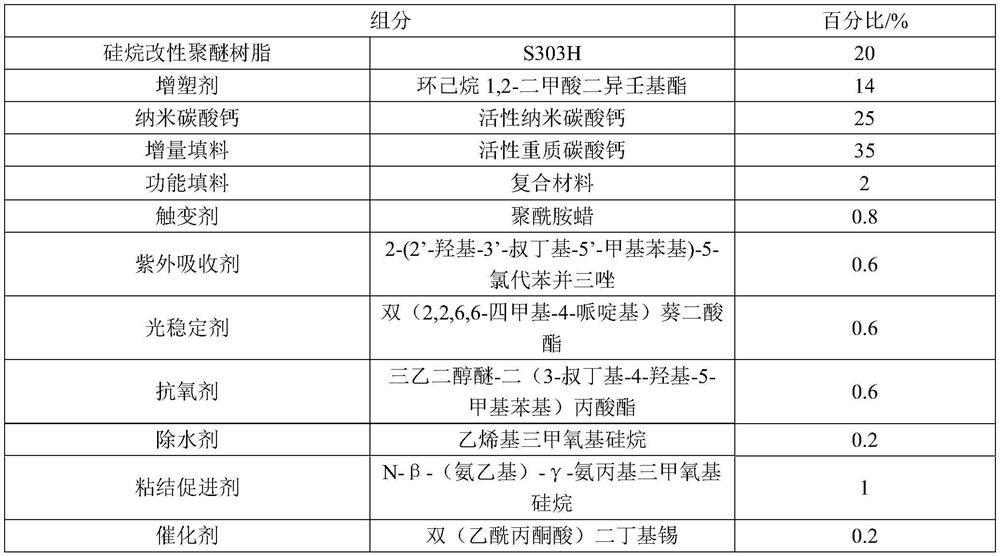

[0041] This example provides a one-component environment-friendly silane-modified polyether sealant for automobiles, and its components and weight percentages are as follows:

[0042]

[0043] Note: The composite materials in the tables of Examples 1-3 and Comparative Examples 1-3 refer to composite materials formed by compounding nano-activated carbon, carbonate, silicate, photocatalyst and heat-activated catalyst, wherein nano-activated carbon, carbonate and The ratio of the total mass of silicate to the total mass of photocatalyst and heat-activated catalyst is 3.3:1.

[0044] The preparation method of the single-component environment-friendly silane-modified polyether sealant for automobiles of the present embodiment comprises the following steps:

[0045] (1) Pre-dry the nano-calcium carbonate and the filler at 110-130°C for 12 hours, and set aside.

[0046] (2) Add silane-modified polyether resin, plasticizer, thixotropic agent, nano-calcium carbonate, extender fille...

Embodiment 2

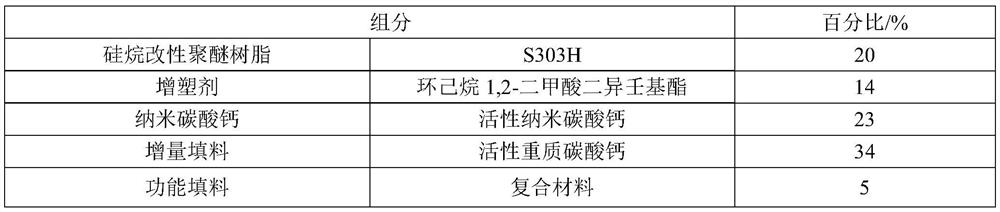

[0049] This example provides a one-component environment-friendly silane-modified polyether sealant for automobiles, and its components and weight percentages are as follows:

[0050]

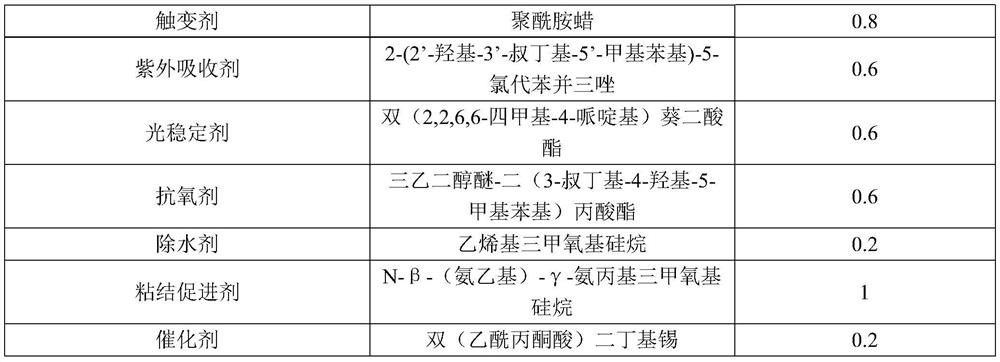

[0051]

[0052] The preparation method of the one-component environment-friendly silane-modified polyether sealant for automobiles in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0054] This example provides a one-component environment-friendly silane-modified polyether sealant for automobiles, and its components and weight percentages are as follows:

[0055]

[0056] The preparation method of the one-component environment-friendly silane-modified polyether sealant for automobiles in this embodiment is the same as that in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com