Ditching layered fertilization device for seeding machine

A layered fertilization and seeder technology is applied in the direction of excavation/covering of trenches, fertilizers and seeding equipment, planting methods, etc. efficiency, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

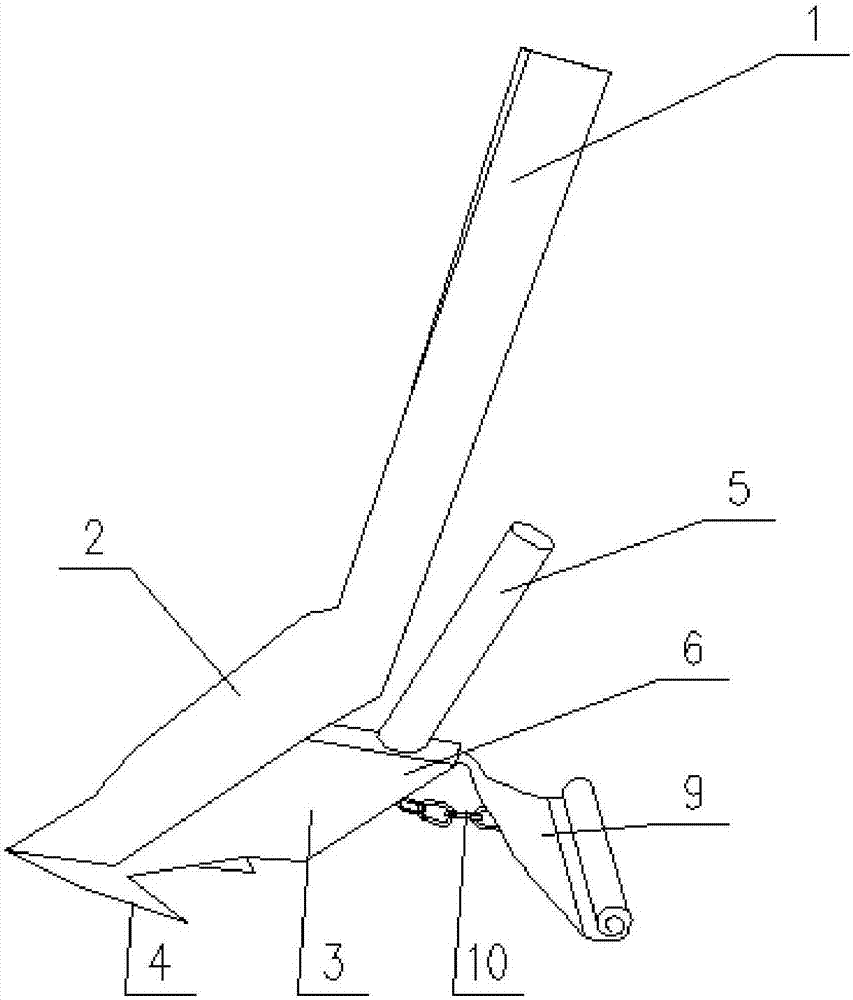

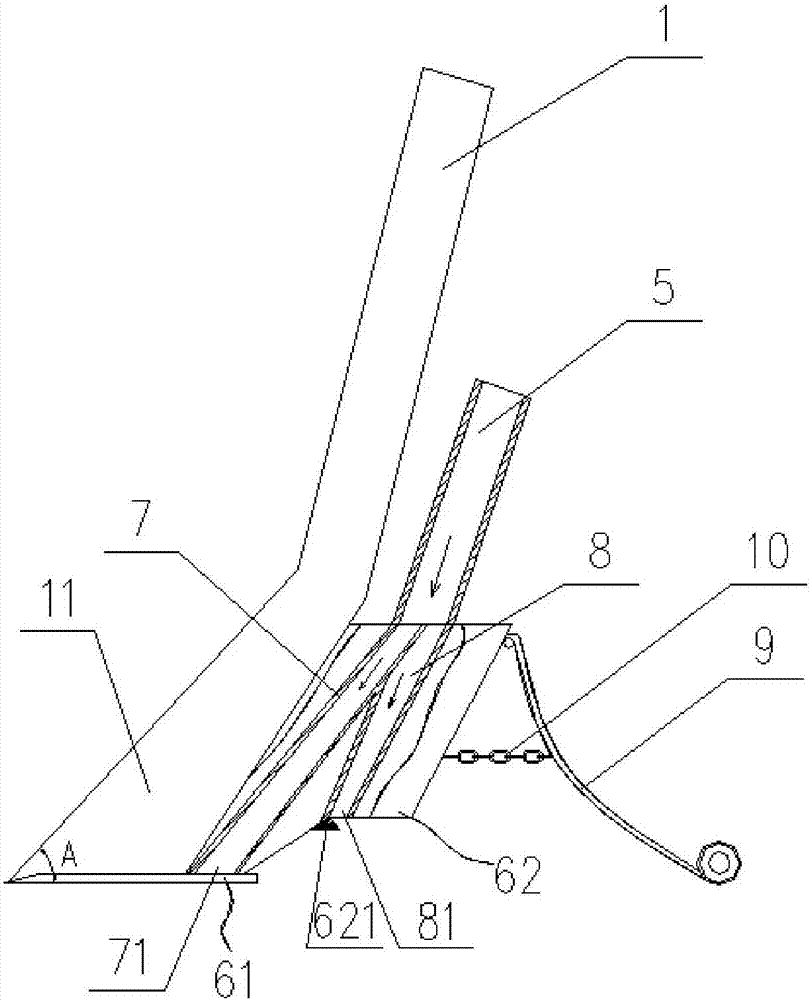

[0017] Specific implementation mode one: combine Figure 1-Figure 2 Describe this embodiment, the planter ditching layered fertilizer applicator of this embodiment comprises support 1, and the front side and the rear side of support are respectively fixedly connected with ditch opener 2 and fertilizer applicator 3, and described ditch opener 2 comprises plow The head 11 and the dovetail-shaped ditching cutter 4, the dovetail-shaped ditching cutter 4 is welded on the lower part of the plowshare 11, the fertilization device 3 includes a fertilization connecting pipe 5 and a fertilization guide box 6, and the fertilization pipe 5 and The fertilization guide box 6 is connected and installed. The inside of the fertilization guide box 6 is provided with a first fertilization pipe 7 and a second fertilization pipe 8. 5 fit. Set up in this way, the seeder ditching layered fertilizer applicator is installed on the agricultural operation machine through the bracket 1, and the front of ...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 1-Figure 2 Describe this embodiment, the lower end of the fertilization guide box 6 described in the seeder ditching and layered fertilizer applicator of this embodiment is provided with a first fertilization part 61 and a second fertilization part 62, and the first fertilization part 61 and the second fertilization part The fertilization part 62 forms a stepped fertilization structure, the first fertilization outlet end 71 of the first fertilization pipe 7 is installed and arranged at the first fertilization part 61, and the second fertilization outlet end 81 of the second fertilization pipe 8 is installed Arranged at the second fertilization part 62 . Set in this way, the fertilizer discharged from the fertilization guide box 6 enters the first fertilization pipe 7 and the second fertilization pipe 8 respectively, and the first fertilization part 61 and the second fertilization part 62 form a stepped fertilization ...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 1-Figure 2 Describe this embodiment, the level difference between the first fertilization part 61 and the second fertilization part 62 provided at the lower end of the fertilization guide box 6 described in the ditching layered fertilizer applicator for the planter of the present embodiment is 8cm-12cm. Set in this way, the level difference between the first fertilizing part 61 and the second fertilizing part 62 is 8-12 cm, and the layering in this interval can make the crops grow in the best work and rest time, effectively supply fertilizer, so that the crops can grow vigorously, and The fruit produced is full.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com