Animal skin dog chew

A technology of livestock fur and dog chews, applied in animal husbandry, animal feed, additional food elements, etc., can solve the problems of dog chews, such as easy to change color and taste, and achieve the goal of increasing color and taste, increasing nutritional and health care value, and good taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

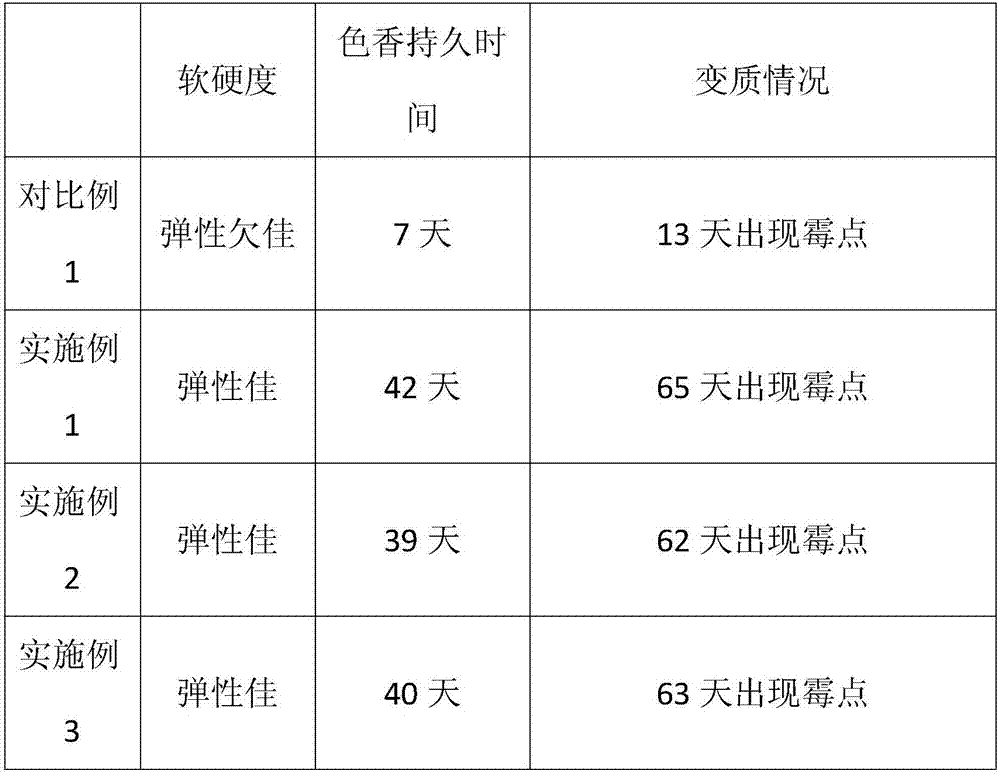

Examples

Embodiment 1

[0027] (1) Prepare materials according to the components of the following parts by mass:

[0028] 60 parts of animal skins,

[0029] 15 parts of toughened particles,

[0030] 0.3 parts of konjac manna gum,

[0031] 5 servings of food powder;

[0032] The toughened particles are prepared according to the following steps:

[0033] a. Dry the corncobs and crush them into powders of 100-150 mesh;

[0034] b. Disperse the powder of step a in a mixed solution of deionized water and ethanol at 6 g / mL to form a suspension, and stir the suspension under ultrasonic conditions to uniformly disperse the powder; the deionized water and ethanol The concentration of ethanol in the mixed solution is 70v / v%;

[0035] c. Add 5wt% citric acid to the suspension in step b, stir well and place it at 4°C for 36 hours at a constant temperature, then at 12°C for 36 hours, then add baking soda until the pH value = 7~8;

[0036] d. Filter with nylon mesh, wash with deionized water, and dry at 60°...

Embodiment 2

[0040] (1) Prepare materials according to the components of the following parts by mass:

[0041] 50 parts of animal skins,

[0042] 10 parts of toughened particles,

[0043] 0.2 parts of konjac manna gum,

[0044] The toughened particles are prepared according to the following steps:

[0045] a. Dry the bagasse and pulverize it into a powder of 100-150 mesh;

[0046] b. Disperse the powder in step a at 1 g / mL in a mixture of deionized water and ethanol to form a suspension, and stir the suspension under ultrasonic conditions to disperse the powder evenly; the deionized water and ethanol The concentration of ethanol in the mixed solution is 60v / v%;

[0047] c. Add 1wt% citric acid to the suspension in step b, stir well and place it at 0°C for 48 hours at a constant temperature, then at 10°C for 45 hours, then add baking soda until the pH value = 7~8;

[0048] d. Filter with nylon mesh, wash with deionized water, and dry at 60°C to obtain toughened particles.

[0049] (2...

Embodiment 3

[0051] (1) Prepare materials according to the components of the following parts by mass:

[0052] 70 parts of animal hides,

[0053] Toughened particles 20 parts,

[0054] 0.5 parts of konjac manna gum,

[0055] 10 parts of food powder;

[0056] The toughened particles are prepared according to the following steps:

[0057] a, bagasse is dried and crushed to 150 mesh powder;

[0058] b. Disperse the powder of step a in a mixed solution of deionized water and ethanol at 8 g / mL to form a suspension, and stir the suspension under ultrasonic conditions to uniformly disperse the powder; the deionized water and ethanol The concentration of ethanol in the mixed solution is 80v / v%;

[0059] c. Add 6wt% citric acid to the suspension in step b, stir well and place it at 8°C for 24 hours at a constant temperature, then at 18°C for 30 hours, then add baking soda until the pH value = 7~8;

[0060] d. Filter with nylon mesh, wash with deionized water, and dry at 60°C to obtain toug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com