Fixed-wing unmanned aerial vehicle body and manufacturing method thereof

A UAV, fixed-wing technology, applied in the field of UAVs, can solve the problems of long time, heavy body weight, reduce the structural strength of UAVs, etc., achieve excellent tensile strength and tear resistance, and reduce maintenance costs And the effect of strong applicability of cycle and appearance design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the fixed-wing unmanned aerial vehicle body of the embodiment of the present invention, described preparation method comprises the following steps:

[0036] In the preheated forming upper mold, paste the layered connection material in the fuselage or wing group, and eliminate the edge;

[0037] In the preheated molding lower mold, stick the layered connection material in the fuselage or wing group, put the insert, install the air duct, and close the upper mold and the lower mold;

[0038] Thermoforming.

[0039] In order to make the above and other purposes, features, and advantages of the present invention more comprehensible, the following examples are given to illustrate the body of the fixed-wing UAV described in the present invention and its preparation method.

Embodiment 1

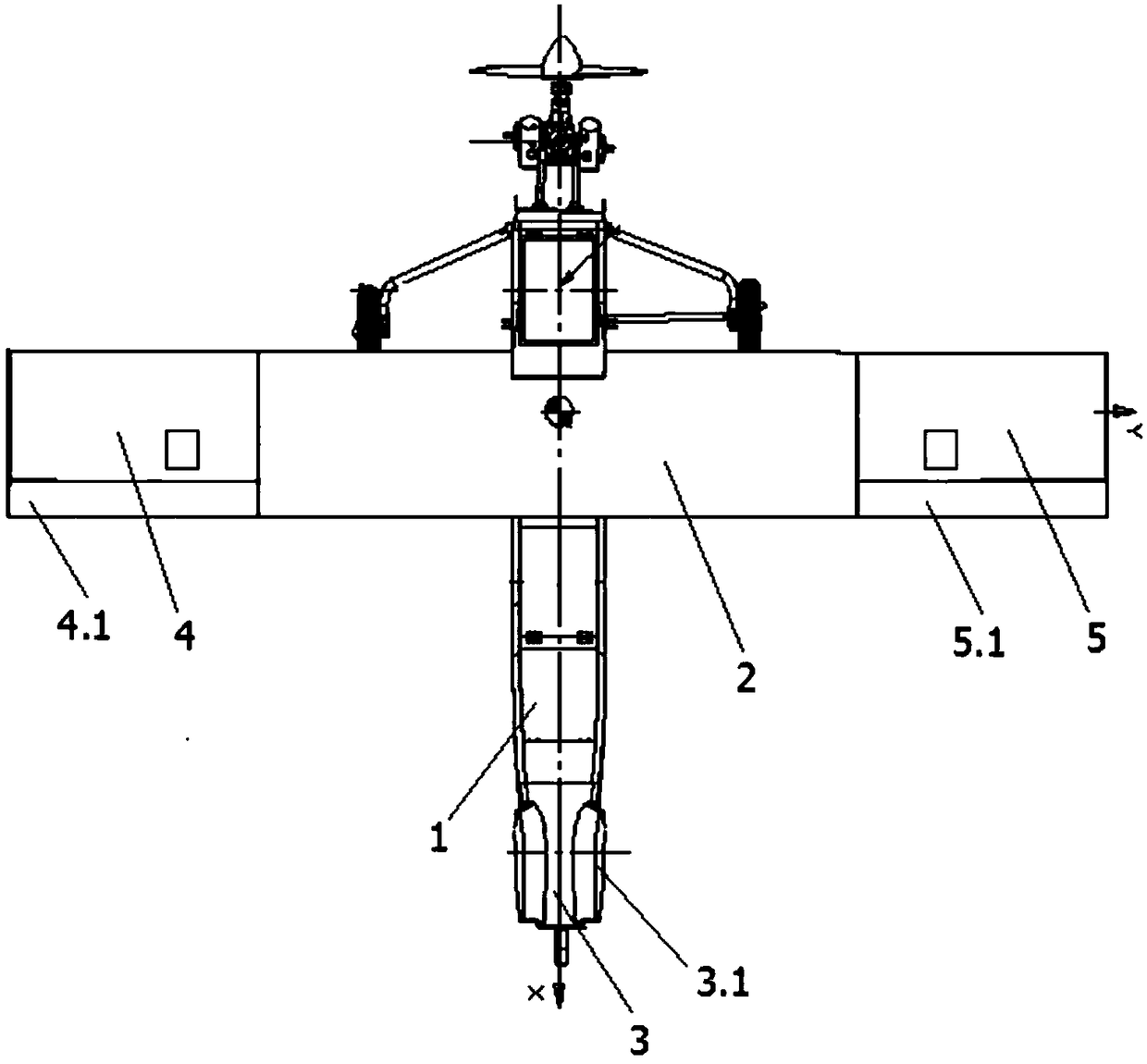

[0041] Such as figure 1 As shown, the fixed-wing unmanned aerial vehicle body prepared by the composite material in Embodiment 1 of the present invention includes a fuselage 1 and a wing group, and the wing group includes a main wing 2 and an empennage 3 respectively arranged on both sides of the fuselage. A wingtip 4 or 5 is respectively arranged on both sides of the main wing 2; the materials of the fuselage 1 and the wing group are layered; the material of the fuselage 1 includes the first glass fiber cloth, the first Carbon fiber cloth, the first polyvinyl chloride cloth and the second carbon fiber cloth; The materials of the main wing 2 and the wing tip 4 or 5 respectively include the first glass fiber cloth, the second glass fiber cloth, the first poly Vinyl chloride cloth and the third glass fiber cloth; the material of the empennage 3 includes the first glass fiber cloth, the second glass fiber cloth, the first polyvinyl chloride cloth and the third glass fiber cloth w...

Embodiment 2

[0053] Such as figure 1 As shown, the fixed-wing unmanned aerial vehicle body prepared by the composite material in Embodiment 1 of the present invention includes a fuselage 1 and a wing group, and the wing group includes a main wing 2 and an empennage 3 respectively arranged on both sides of the fuselage. A wingtip 4 or 5 is respectively arranged on both sides of the main wing 2; the materials of the fuselage 1 and the wing group are layered; the material of the fuselage 1 includes the first glass fiber cloth, the first Carbon fiber cloth, the first polyvinyl chloride cloth and the second carbon fiber cloth; The materials of the main wing 2 and the wingtips 4, 5 respectively include the first glass fiber cloth, the second glass fiber cloth, the first poly Vinyl chloride cloth and the third glass fiber cloth; the material of the empennage 3 includes the first glass fiber cloth, the second glass fiber cloth, the first polyvinyl chloride cloth and the third glass fiber cloth whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com