Ship exhaust and ballast water integrated treatment system

A ship exhaust and treatment system technology, applied in the environmental field, can solve the problems of limited space, load and generator power waste of ships, and achieve the effects of increasing gas-liquid mass transfer efficiency, reducing liquid-gas ratio, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

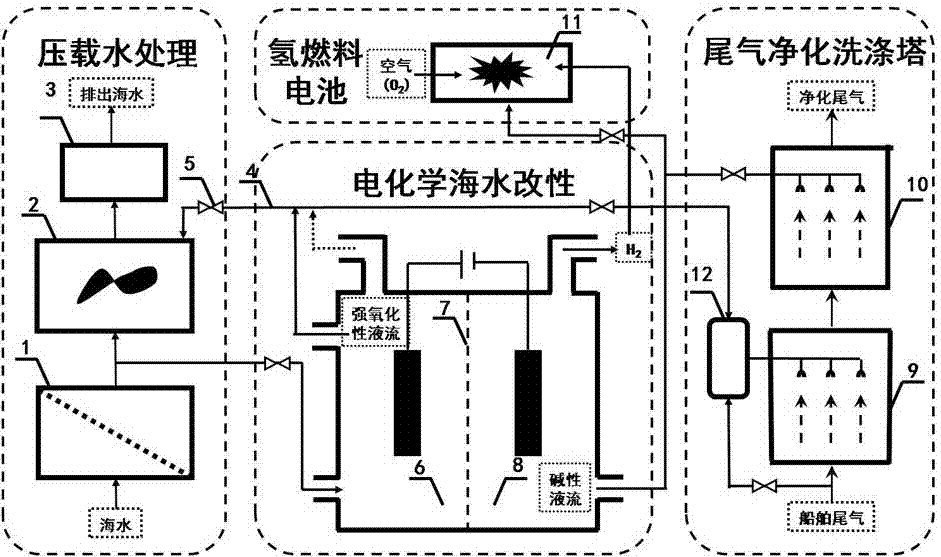

[0054] As a specific example, such as figure 1 As shown, an integrated treatment system for ship tail gas and ballast water according to the present invention includes an electrochemical seawater modification reactor, a ballast water treatment reactor and a tail gas purification scrubber. Specifically include: filter 1; oxidation deactivation component 2; subsequent discharge reduction component 3; pipeline 4; valve 5; anode cavity 6; diaphragm 7; cathode cavity 8; oxidation scrubber 9, alkaline absorption scrubber 10, hydrogen fuel A battery reactor 11 and a micro-nano bubble generating device 12 . The above-mentioned components are connected through the pipeline 4 as a gas path and a liquid path.

[0055] The strong oxidizing liquid flow is generated in the anode cavity 6, and is transported to the oxidation inactivation component 2 to oxidize an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com