Polyimide foamed plastic and preparation method thereof

A technology of polyimide and foam plastics, which is applied in the field of polyimide foam plastics and its preparation, can solve the problems of difficult crushing into uniform powder, complicated process preparation, and no reports, and achieve consistent temperature resistance and preparation The effect of simple process and increased compression modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Mix 20.02g (0.1mol) of 4'4-diaminodiphenyl ether with 40.38g of methanol and 161.53g of tetrahydrofuran and add 27.92g (0.09mol) of 3,3',4,4' - diphenyl ether tetra-acid dianhydride, react at 50° C. for 4 hours, then add 2.54 g (0.01 mol) of pyromellitic acid and continue the reaction for 4 hours to obtain a polyimide precursor solution.

[0034] (2) The solution in step (1) was dried at room temperature, and then placed in a vacuum oven at 60° C. for 10 hours to form a brittle solid. Take it out and crush it into powder with uniform particle size.

[0035] (3) paving the powder in step (2) on a volume of 1670cm 3 In the mold, put it into a high-temperature furnace at 250° C. to close the mold and foam for 1 hour to obtain the final polyimide foam.

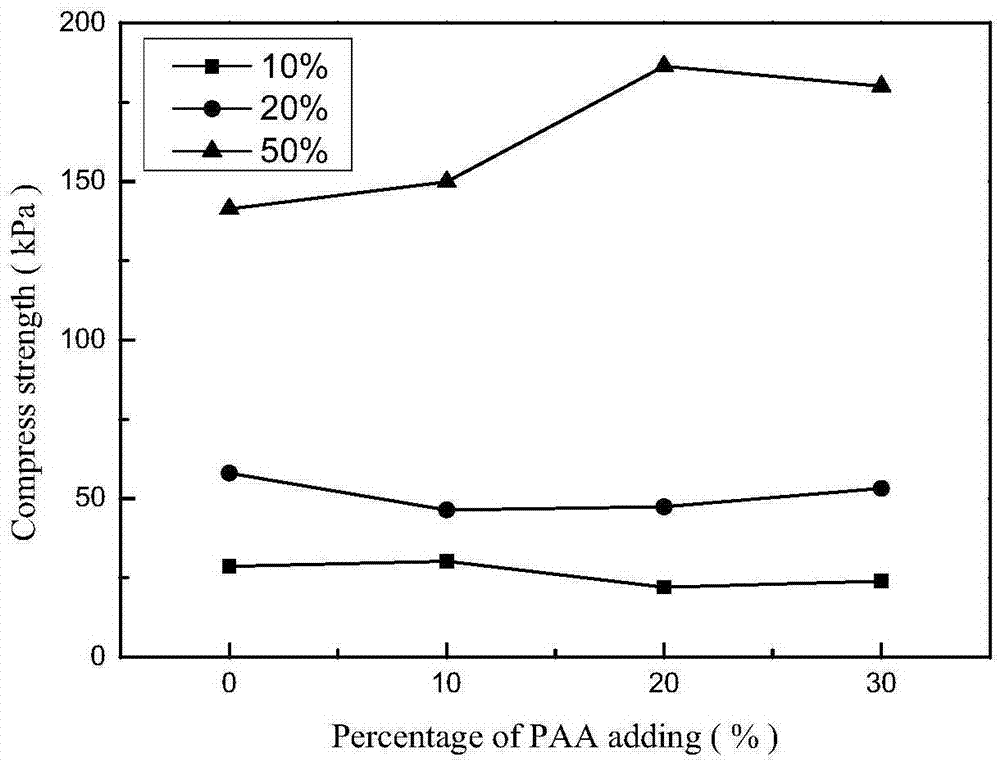

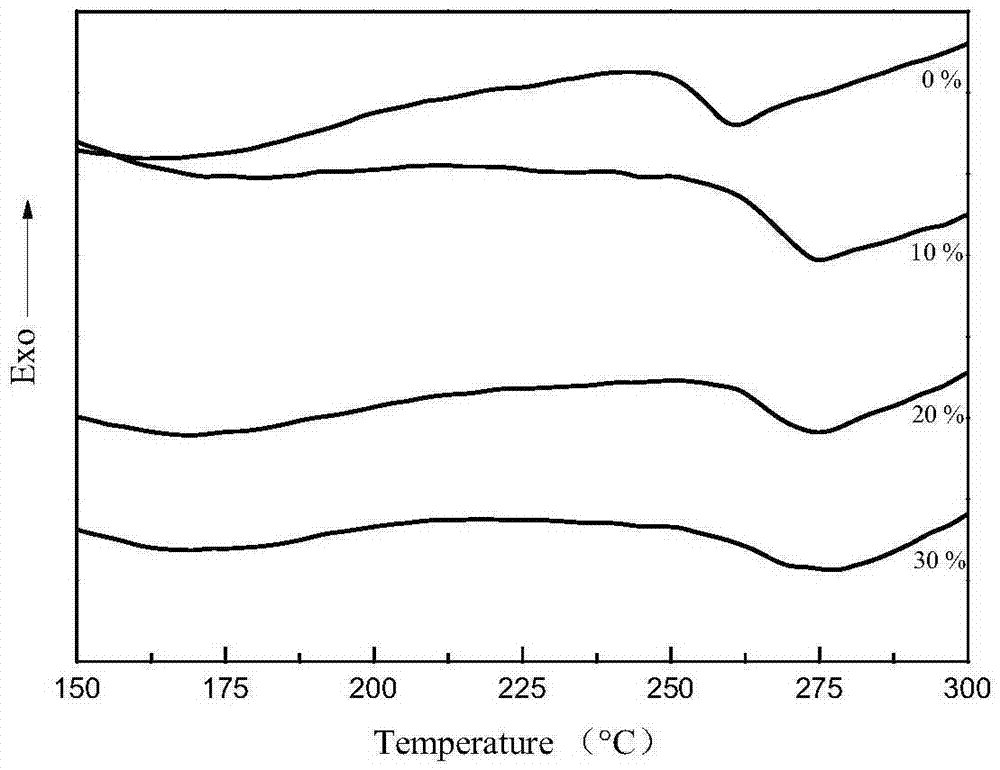

[0036] The polyimide foamed plastics in the present embodiment is measured, and the density of this foam is 33.3Kg / m 3 , the glass transition temperature is 275°C, the 5% thermal weight loss is 570°C, the compressive...

Embodiment 2

[0038] (1) Mix 20.02g (0.1mol) of 4'4-diaminodiphenyl ether with 40.38g of methanol and 161.53g of tetrahydrofuran, then add 21.71g (0.07mol) of 3,3',4,4' -Diphenyl ether tetraacid dianhydride, react at 30°C for 2 hours, then add 7.62g (0.03mol) of pyromellitic acid to continue the reaction for 1 hour, then add 1.03g of polydimethylsiloxane to obtain polyimide precursor solution.

[0039](2) Pour out the solution in step (1) until it stops flowing, and then put it into a vacuum oven at 60° C. for 20 hours to vacuum dry to form a brittle solid. Take it out and crush it into powder with uniform particle size.

[0040] (3) pave the powder in step (2) to a volume of 960cm 3 In the mold, put it into a high-temperature furnace at 240° C. to close the mold and foam for 1 hour to obtain the final polyimide foam.

[0041] The polyimide foamed plastics in the present embodiment is measured, and the density of this foam is 47.5Kg / m 3 , the glass transition temperature is 277°C, the 5...

Embodiment 3

[0043] (1) Mix 19.83g (0.1mol) of 4'4-diaminodiphenylmethane with 40.23g of methanol and 160.93g of tetrahydrofuran and add 27.92g (0.09mol) of 3,3',4,4' -Diphenyl ether tetraacid dianhydride, react at 40°C for 6 hours, then add 2.54g (0.01mol) of pyromellitic acid to continue the reaction for 4 hours, then add 1.03g of polydimethylsiloxane to obtain polyimide precursor solution.

[0044] (2) Pour the solution of step (1) into a container, put it into a vacuum oven at 40° C. for 10 hours and vacuum dry it to form a brittle solid after it stops flowing. Take it out and crush it into powder with uniform particle size.

[0045] (3) paving the powder in step (2) on a volume of 1670cm 3 In the mold, put it into a high-temperature furnace at 250° C. to close the mold and foam for 1 hour to obtain the final polyimide foam.

[0046] The polyimide foam plastic in the present embodiment is carried out performance measurement, and the density of this foam is 37.8Kg / m 3 , the glass tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com