A method for synthesizing microporous conductive polymer material with nanoreactor

A nanoreactor, conductive polymer technology, applied in nanotechnology, electrolysis components, electrolysis process, etc., can solve the problems of few electrochemical applications, low conductivity, etc., achieve reversible redox cyclic voltammetry properties, good semiconductor Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

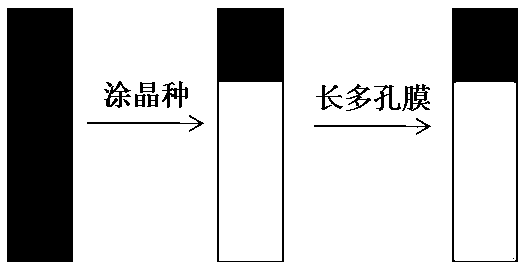

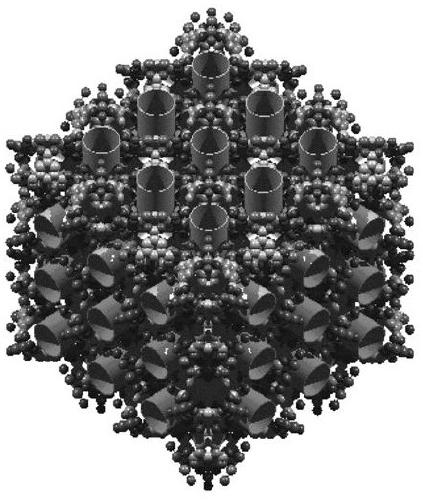

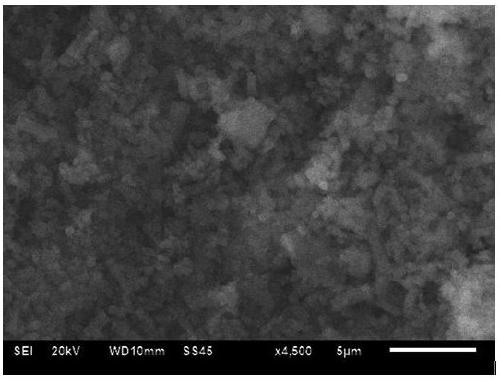

[0035] The method for synthesizing a microporous conductive polymer material with a nanoreactor comprises the following steps:

[0036](1) Platinum sheet (1 cm × 5 cm × 0.5 mm) was polished with 500-mesh sandpaper and corroded with 20% hydrochloric acid solution for 20-30 seconds. After taking it out from the hydrochloric acid, it was ultrasonically cleaned with ethanol 3 times, each time 30 minutes, and finally ultrasonic cleaning with deionized water 3 times, 30 minutes each time. Allow to dry at room temperature. Brush the emulsion of MIL-68 seed crystals on both sides of the pretreated platinum sheet (the 1cm uncoated area is convenient for later electrode use). The platinum sheet modified with the seed crystal is placed in a 60 degree oven and dried overnight, and the solution for dissolving the MIL-68 seed crystal can be chloroform.

[0037] (2) Place the non-seeded end of the seed-modified platinum sheet obtained in the previous step upwards and place it in the lining...

Embodiment 2

[0043] The difference from Example 1 of the method for synthesizing microporous conductive polymer materials using a nanoreactor is that when polythiophene is prepared by cyclic voltammetry, the concentration of thiophene in the electrolyte is 0.2 M.

Embodiment 3

[0045] The difference from Example 1 of the method for synthesizing microporous conductive polymer materials using nanoreactors is that the scan rate (sweep rate) is 20 mV / s when polythiophene is prepared by cyclic voltammetry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com