Cell plating device taking magnetic liquid as medium

A magnetic liquid and medium technology, applied in the field of biomedical engineering, can solve problems such as failure, and achieve the effect of maintaining cell activity and uniform plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

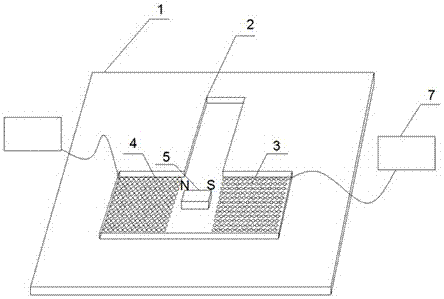

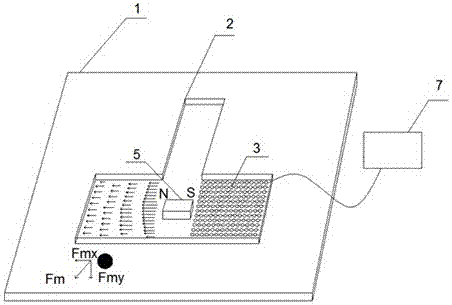

[0031] A cell plating device using magnetic liquid as the medium, including a silicon chip substrate 1 (rectangular 100×100mm), T-shaped channel 2, microcoil I3, microcoil II4, permanent magnet I5, permanent magnet II6, programmable AC power supply 7. Microcoil I3 and microcoil II4 are provided on the silicon wafer substrate 1 (in this embodiment, microcoil I3 and microcoil II4 are fabricated on the silicon wafer substrate 1 by photolithography and electroplating), microcoil I3 and microcoil II4 On a straight line with a gap between the two; the T-shaped channel 2 is sealed and fixed on the silicon substrate 1, the microcoil I3 and the microcoil II4 are located below the horizontal channel of the T-shaped channel 2, the microcoil I3 and the microcoil The gap between II4 is directly opposite to the vertical channel of T-shaped channel 2; there is a transparent cover plate above T-shaped channel 2, and the cover plate is provided with permanent magnet I5 or permanent magnet II6, ...

Embodiment 2

[0035] Referring to the structure of embodiment 1, the difference between this embodiment and embodiment 1 is that the number of permanent magnets I5 and permanent magnets II6 are two or more respectively. This magnet structure can generate a higher gradient magnetic field and increase the magnetic fluid The magnetic buoyancy force on the cell.

Embodiment 3

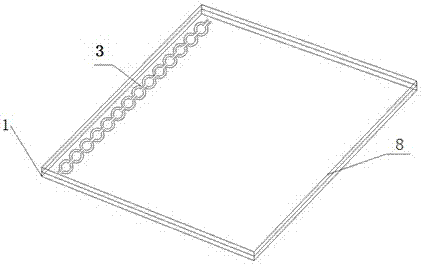

[0037]With reference to the structure of Embodiment 1, the difference between this embodiment and Embodiment 1 is that the microcoil I3 of the present invention is in the form of a rectangular cell, including a plurality of parallel top wires 10 and a plurality of bottom wires 9 parallel to each other, and the top An isolation layer is provided between the wire 10 and the bottom wire 9, the bottom wire 9 is located on the silicon substrate 1, the top wire 10 is located on the isolation layer, the top wire 10 and the bottom wire 9 are perpendicular to each other, and have a 90° phase difference of sine and cosine The current is applied to the two crossed wires at the same frequency f to generate a magnetic field gradient. The microcoil II4 has the same structure as the microcoil I3; the line spacing between the microcoil I3 and the microcoil II4 is 10 mu m and 20 mu m, wire diameter is 4 mu m, sine and cosine currents with a 90° phase difference are applied to the crossed two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com