High-property non-combustible external wall thermal-insulation decorative sheet and preparation method thereof

A technology for external wall insulation and decorative panels, applied in chemical instruments and methods, household walls, lamination devices, etc., can solve the problems of poor thermal insulation performance, poor combustion performance, poor fireproof performance, etc., achieve convenient cleaning and maintenance, and overcome strength The effect of low and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

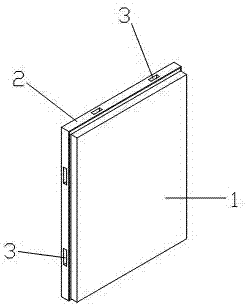

[0046] Such as figure 1 As shown, this embodiment provides a high-performance non-combustible exterior wall thermal insulation decorative panel, which includes a substrate 1 in a rectangular thin plate structure, and covers the upper surface of the substrate, and is folded 90° around the upper surface of the four sides of the substrate. The metal panel box 2; the metal panel box 2 on the four sides of the substrate 1 are each provided with at least two elongated frame notches 3. The thermal insulation decorative board has good fire-proof and thermal insulation effect, is convenient to install, and has a beautiful appearance.

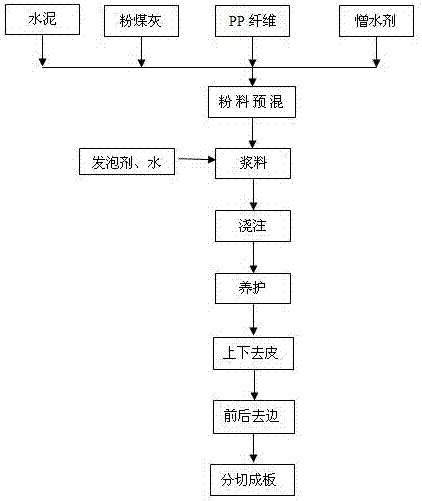

[0047] Such as Figure 2~4 As shown, the preparation method of the high-performance non-combustible external wall thermal insulation decorative board includes the following three steps:

[0048] 1) Preparation method of substrate;

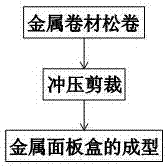

[0049] 2) Forming of metal panel box;

[0050] 3) Composite molding of decorative panels.

[0051] Such as figure 2 As shown, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com