Composite molding nano plate and preparation method thereof

A technology of composite mold and nano-board, applied in the direction of building components, heat preservation, etc., to achieve the effects of good flexibility, high combustion level, and ultra-low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

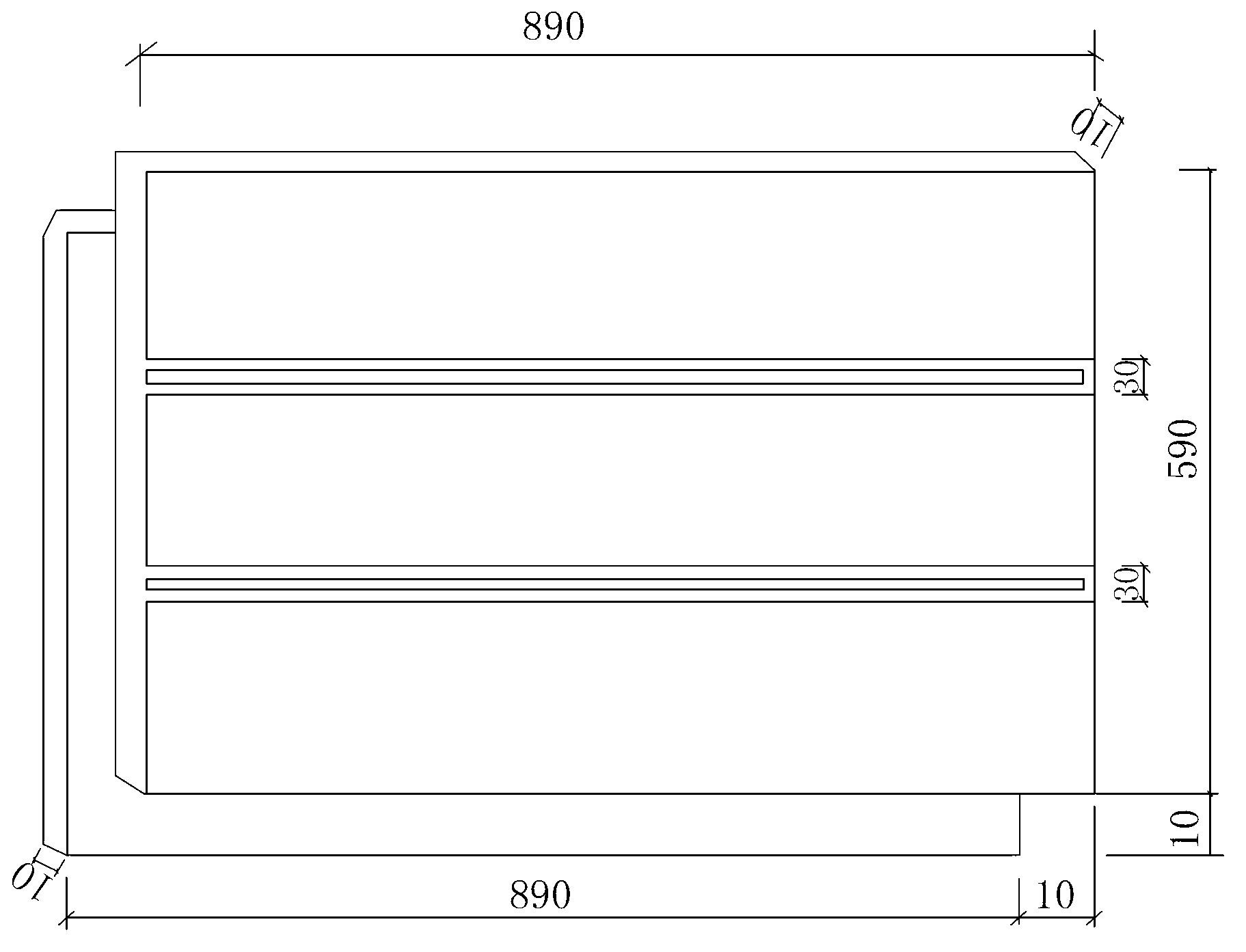

Image

Examples

Embodiment 1

[0041] Composite molded nanoplates, which consist of styrene, deionized water, dibenzoyl peroxide (BPO), tert-butyl perbenzoate (T-BPB), hydroxyethyl cellulose (HEC), calcium hydroxyphosphate ( TCP), sodium pyrophosphate, pentane, sodium butylnaphthalene sulfonate and expandable graphite raw materials are produced by batch suspension polymerization process to form an expandable polymer, and then pre-foamed and molded into a board that is convenient for engineering construction type (i.e. composite molded nanoplate); the mass parts of each raw material are: 100 parts of styrene, 120 parts of deionized water, 0.4 parts of dibenzoyl peroxide (BPO), tert-butyl perbenzoate (T -BPB) 0.07 parts, hydroxyethyl cellulose (HEC) 0.1 parts, calcium hydroxyphosphate (TCP) 0.4 parts, sodium pyrophosphate 0.02 parts, pentane 8 parts, sodium butylnaphthalene sulfonate 8 parts, expandable graphite 1.0 share.

[0042] The styrene mentioned is produced by BASF (China) Co., Ltd.

[0043] The said ...

Embodiment 2

[0070] Basically the same as Example 1, the difference is that the mass parts of each raw material are different, the present embodiment: the mass parts of each raw material are: 100 parts of styrene, 120 parts of deionized water, dibenzoyl peroxide (BPO) 0.3 parts, tert-butyl perbenzoate (T-BPB) 0.08 parts, hydroxyethyl cellulose (HEC) 0.1 parts, hydroxycalcium phosphate (TCP) 0.5 parts, sodium pyrophosphate 0.02 parts, pentane 8 parts , 8 parts of sodium butylnaphthalene sulfonate, and 1.5 parts of expandable graphite.

[0071] Its preparation method is the same as that of Example 1 (only the mass parts of each raw material are different).

[0072] The composite molded nanoplate prepared in this embodiment is tested as follows:

[0073] 1. Thermal conductivity test: According to GB / T 10294 test, the experimental result is 0.0279 W / ﹙m*k﹚, which shows that the thermal conductivity of the present invention is low.

[0074] 2. Breaking bending load test: according to GB / T 8812...

Embodiment 3

[0082] Basically the same as Example 1, the difference is that the mass parts of each raw material are different, the present embodiment: the mass parts of each raw material are: 100 parts of styrene, 120 parts of deionized water, dibenzoyl peroxide (BPO) 0.4 parts, tert-butyl perbenzoate (T-BPB) 0.06 parts, hydroxyethyl cellulose (HEC) 0.1 parts, hydroxycalcium phosphate (TCP) 0.4 parts, sodium pyrophosphate 0.02 parts, pentane 8 parts , 8 parts of sodium butylnaphthalene sulfonate, and 1.2 parts of expandable graphite.

[0083] Its preparation method is the same as that of Example 1 (only the mass parts of each raw material are different).

[0084] The composite molded nanoplate prepared in this embodiment is tested as follows:

[0085] 1. Thermal conductivity test: According to GB / T 10294 test, the experimental result is 0.0279 W / ﹙m*k﹚, which shows that the thermal conductivity of the present invention is low.

[0086] 2. Breaking bending load test: according to GB / T 8812...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com