A High Performance Tunnel Fireproof Decoration System

A high-performance, tunnel technology, used in tunnels, tunnel lining, fire prevention, etc., can solve the problems affecting durability and fire resistance, difficult service life, halogen return, etc., to enhance fire protection and thermal insulation performance, improve compressive strength. , the effect of increasing fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

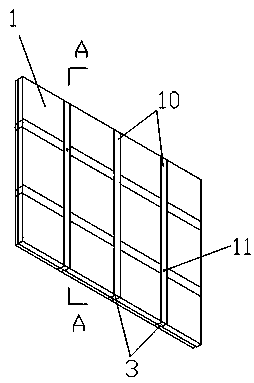

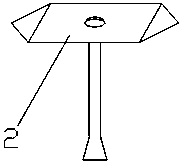

[0037] The purpose of this embodiment is to provide a high-performance tunnel fireproof decoration system, such as figure 1 As shown, the system is set on the tunnel wall in the tunnel, including a fireproof decorative panel 1, anchors 2, vent holes 11, fireproof expansion sealing strip 3 and flame retardant silicone sealant 10;

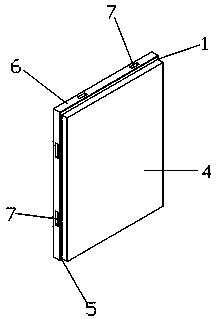

[0038] Such as figure 2As shown, the fireproof decorative panel 1 includes a substrate 4 with a rectangular thin plate structure, a metal panel box 5 covering the upper surface of the substrate 4, and a fluorocarbon paint layer 6 coated on the outer surface of the metal panel box; wherein, the metal The panel box 5 is formed by pressing a metal panel. After pressing, the metal panel box 5 is folded around 90° and wraps the upper parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com