Halogen-free flame-retardant polypropylene composite material and preparation method thereof

A flame retardant polypropylene and composite material technology, applied in the field of polymer material modification, can solve human and environmental hidden dangers, toxicity, suffocation and other problems, achieve excellent mesoporous properties, reduce smoke density, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

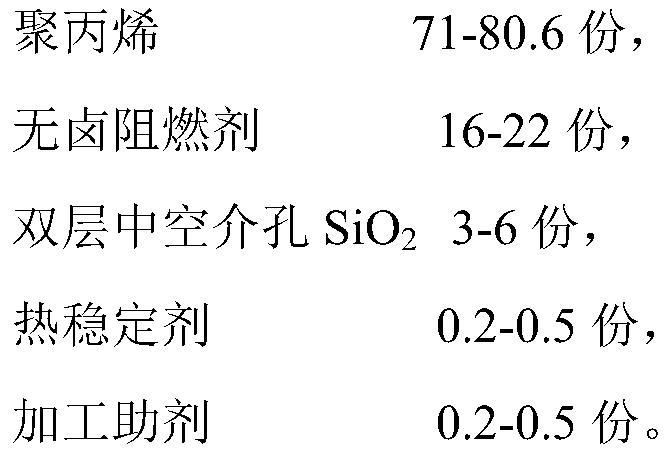

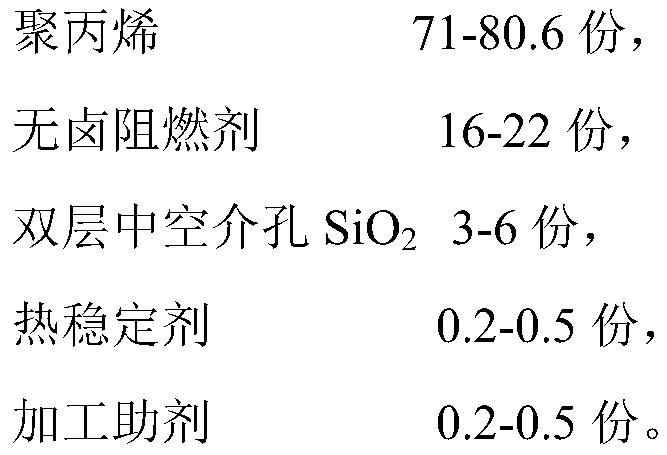

Method used

Image

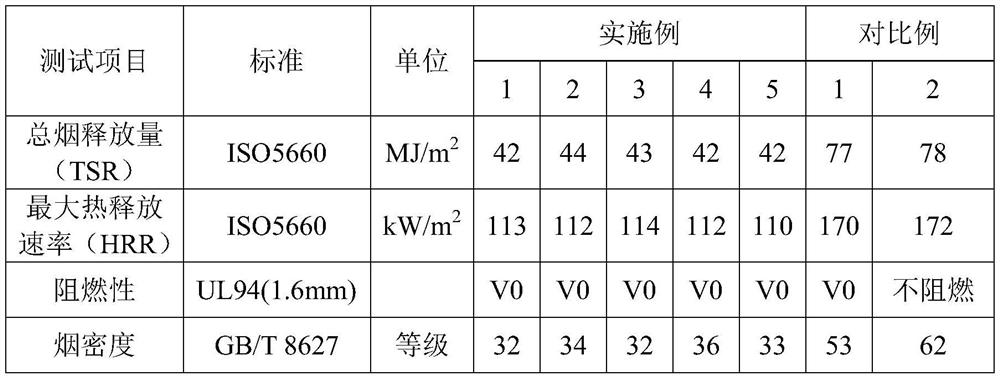

Examples

Embodiment 1

[0030] 75.4 parts of the copolymer polypropylene PP K7227H (Wuhan ethylene), 20 parts of halogen-free flame WR02B (Suzhou An Hongtai), 4 parts of parts made of hollow double shell mesoporous SiO 2 Material, 0.3 parts of a thermal stabilizer 1010 and 0.3 parts of calcium stearate processing aid is added in the aspect ratio of the mixed high-speed mixer is 36: 1 twin screw extruder melt mixing dispersion, extrusion granulation, to obtain a new free flame retardant polypropylene composite material. Wherein the twin screw extruder from the feeding zone to the head temperature were 170 ℃, 170 ℃, 180 ℃, 180 ℃, 180 ℃, 190 ℃, 190 ℃, 195 ℃, 195 ℃, 195 ℃.

[0031] Double hollow mesoporous SiO 2 Preparation method:

[0032] Preparation of emulsion dispersion of a styrene:

[0033] (1) take 15mL of styrene, respectively, after concentration of 10% NaOH solution and washed three times with distilled water reserve;

[0034] (2) are respectively connected to the three-necked flask with a mechani...

Embodiment 2

[0047] 76.4 parts of the homopolymer polypropylene PP T30S (Petrochemical), 18 parts of halogen-free flame WR02B (Suzhou An Hongtai), 5 parts of parts made of hollow double shell mesoporous SiO 2Material, 0.3 parts of a heat stabilizer 168 and 0.3 parts of erucamide processing aid are mixed in a high speed mixer uniformly added an aspect ratio of 40: 1 twin screw extruder melt mixing dispersion, extrusion granulation, to give halogen flame retardant polypropylene composite material. Wherein the twin screw extruder from the feeding zone to the head temperature were 170 ℃, 170 ℃, 180 ℃, 180 ℃, 180 ℃, 190 ℃, 190 ℃, 200 ℃, 200 ℃, 200 ℃.

[0048] Double hollow mesoporous SiO 2 Preparation method:

[0049] Preparation of emulsion dispersion of a styrene:

[0050] (1) take 15mL of styrene, respectively, after concentration of 9% NaOH solution and washed three times with distilled water reserve;

[0051] (2) are respectively connected to the three-necked flask with a mechanical stirrer, c...

Embodiment 3

[0064] 74.2 parts of the copolymer polypropylene PP EA5075 (Basel), 21 parts of halogen-free flame WR02B (Suzhou An Hongtai), 4 parts of parts made of hollow double shell mesoporous SiO 2 Material, 0.2 parts of a heat stabilizer and 1010 parts of a heat stabilizer 0.2 DSTDP, 0.4 parts of zinc stearate processing aid is added after the high speed mixer mixed aspect ratio of 38: 1 twin screw extruder melt mixing dispersion , extrusion granulation, halogen-free flame retardant polypropylene composite material. Wherein the twin screw extruder from the feeding zone to the head temperature were 180 ℃, 180 ℃, 185 ℃, 185 ℃, 190 ℃, 190 ℃, 190 ℃, 200 ℃, 200 ℃, 195 ℃.

[0065] Double hollow mesoporous SiO 2 Preparation method:

[0066] Preparation of emulsion dispersion of a styrene:

[0067] (1) take 15mL of styrene, respectively, after concentration of 9% NaOH solution and washed three times with distilled water reserve;

[0068] (2) are respectively connected to the three-necked flask wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com