Method for packaging LED lamp beads with high Bin drop rate

A technology of LED lamp beads and packaging method, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of LED product brightness, poor color consistency, uneven particle size distribution of phosphor powder, and insufficient mixing of packaging glue. , to achieve the effect of high screening efficiency, narrowing particle size range and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

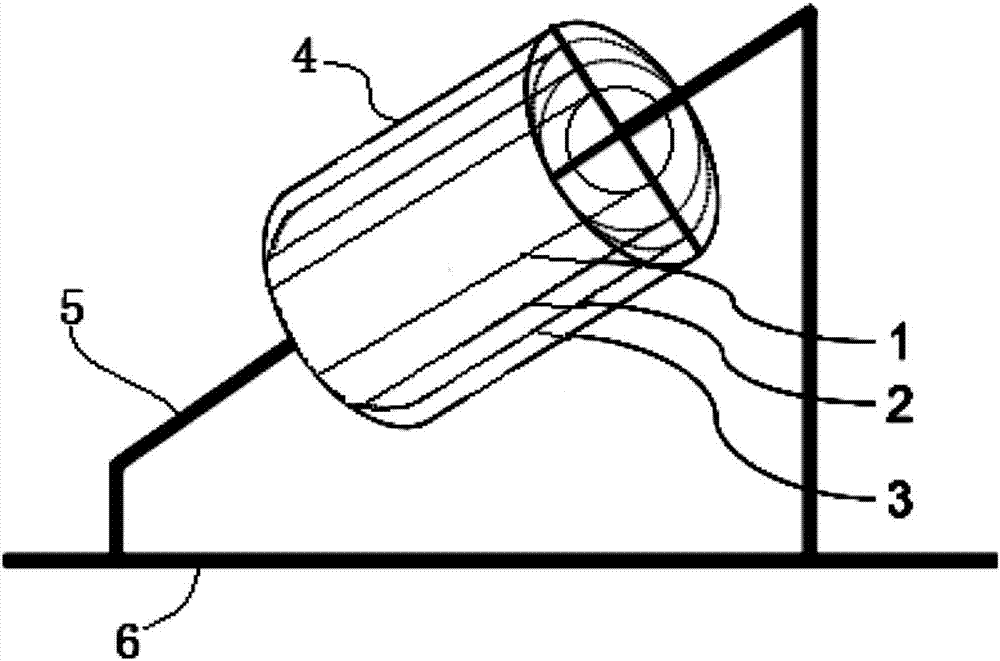

[0034] This embodiment provides a method for packaging LED lamp beads with a high bin drop rate. First, a drum-type phosphor powder screening device is used to screen phosphor powder. The drum-type phosphor powder screening device is as follows: figure 1 As shown, the device includes at least two layers of sieving barrels that are sequentially sleeved from the center to the outside, and the barrel wall of each layer of the sieving barrels is provided with sieve holes, and the sieve holes of each layer of sieving barrels from the inside to the outside Apertures decrease sequentially, and the screening bucket is also connected with a rotary drive mechanism for driving it to rotate and a vibrating mechanism for vibrating it. The rotary drive mechanism is a conventional drive motor, and the vibrating mechanism is a vibrating motor.

[0035]In this embodiment, the screening barrels are 4 layers, which are set sequentially from the inside to the outside, and the mouths of the barrels...

Embodiment 2

[0046] This embodiment provides a drum-type fluorescent powder screening device, the device includes at least two layers of screening barrels set in sequence from the center to the outside, the barrel wall of each layer of the screening barrels is provided with sieve holes, and the The sieve hole diameter of each layer of screening buckets from inside to outside decreases sequentially. The screening bucket is also connected with a rotary drive mechanism for driving its rotation and a vibrating mechanism to vibrate it. The rotary drive mechanism is a conventional drive motor. The vibration mechanism is a vibration motor.

[0047] In this embodiment, the screening barrels are 6 layers, which are set sequentially from the inside to the outside, and the mouths of the barrels are in the same direction. From the inside to the outside, they are the first screening barrel to the sixth screening barrel. The sieve apertures of the sixth sieving buckets decrease successively. In this emb...

Embodiment 3

[0056] This embodiment provides a drum-type fluorescent powder screening device, the device includes at least two layers of screening barrels set in sequence from the center to the outside, the barrel wall of each layer of the screening barrels is provided with sieve holes, and the The sieve hole diameter of each layer of screening buckets from inside to outside decreases sequentially. The screening bucket is also connected with a rotary drive mechanism for driving its rotation and a vibrating mechanism to vibrate it. The rotary drive mechanism is a conventional drive motor. The vibration mechanism is a vibration motor.

[0057] In this embodiment, the screening barrels are 8 layers, which are set sequentially from the inside to the outside, and the mouths of the barrels are in the same direction. From the inside to the outside, they are the first screening barrel to the eighth screening barrel. The sieve apertures of the eighth sieving bucket decrease successively. In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com