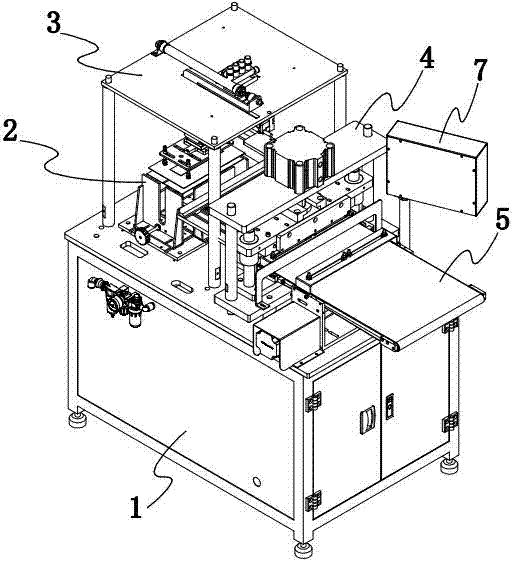

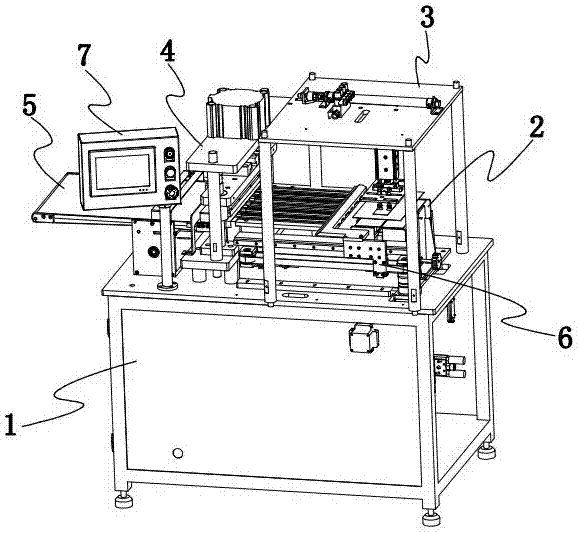

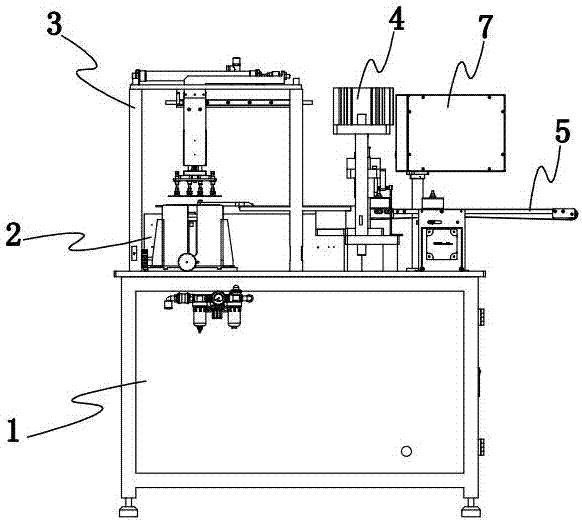

Battery pole piece guillotine

A battery pole piece and cutting machine technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of inability to realize continuous cutting and processing, the large space occupied by the machine body, and insufficient production efficiency, so as to achieve continuous automation and high efficiency The effect of cutting, reducing labor costs, and reasonable structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First, stack the battery pole piece 35 on the discharge plate 28 in the feeder 27 of the feeding mechanism 2 of the body, then the body control panel 7 controls the operation of the feeding drive motor 21 of the feeding mechanism 2, and the feeding mechanism 2 The push rod 25 at the top of the push block 24 is driven by the material drive motor 21, and the height position of the discharge plate 28 on the top of the push rod 25 and the battery pole piece 35 on the discharge plate 28 is adjusted up and down. When the battery pole piece 35 is adjusted to a suitable position , the body control panel 7 controls the feed drive cylinder 31 piston rod of the feed mechanism 3 to expand and contract, the feed drive cylinder 31 drives the adsorption cylinder 36 on the installation slat 32 to move to the top of the battery pole piece 35, and then the body control panel 7 controls the body control panel 7. The suction cup 34 on the telescopic rod moves down to absorb the battery pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com