Electrodynamic induction loudspeaker

A loudspeaker, electrodynamic technology, applied in the field of loudspeakers, can solve the problems of low sensitivity and large misalignment of ordinary inductive loudspeakers, and achieve the effect of ensuring isotropy, reducing distortion, and reducing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

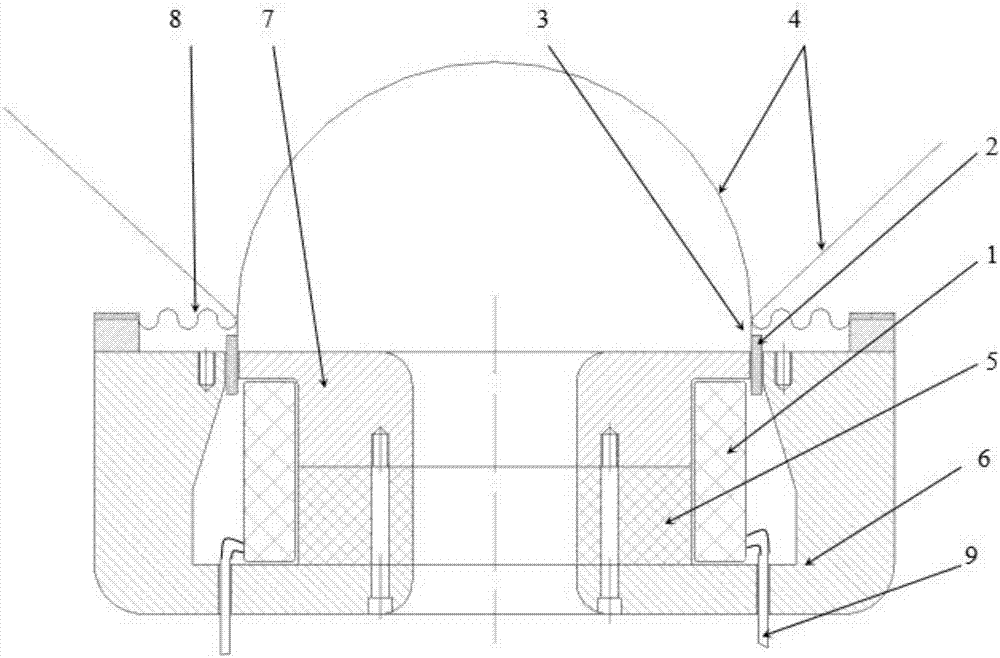

[0037] An internal magnetic induction electrodynamic loudspeaker, such as figure 1 As shown, it includes excitation coil 1, induction voice coil 2, voice coil bobbin 3, sound membrane 4, magnet steel 5, lower magnetic plate 6, upper magnetic splint 7, centering strut 8 and signal feeder 9. The magnetic steel 5 is installed between the central columns of the lower magnetically conductive plate 6 and the upper magnetically conductive splint 7 and is fixed or glued together by bolts. The excitation coil 1 is fastened on the central magnetic pole composed of the lower end of the upper magnetic splint 7 and the magnetic steel 5. The excitation coil 1 is connected to the signal feeder 9 and the signal feeder passes through the passage of the lower magnetic conductive plate. hole and connect the external audio current signal. The magnetic steel 5 is a permanent magnet with high resistivity, and the upper magnetically conductive splint 7 and the lower magnetically conductive plate 6 ...

Embodiment 2

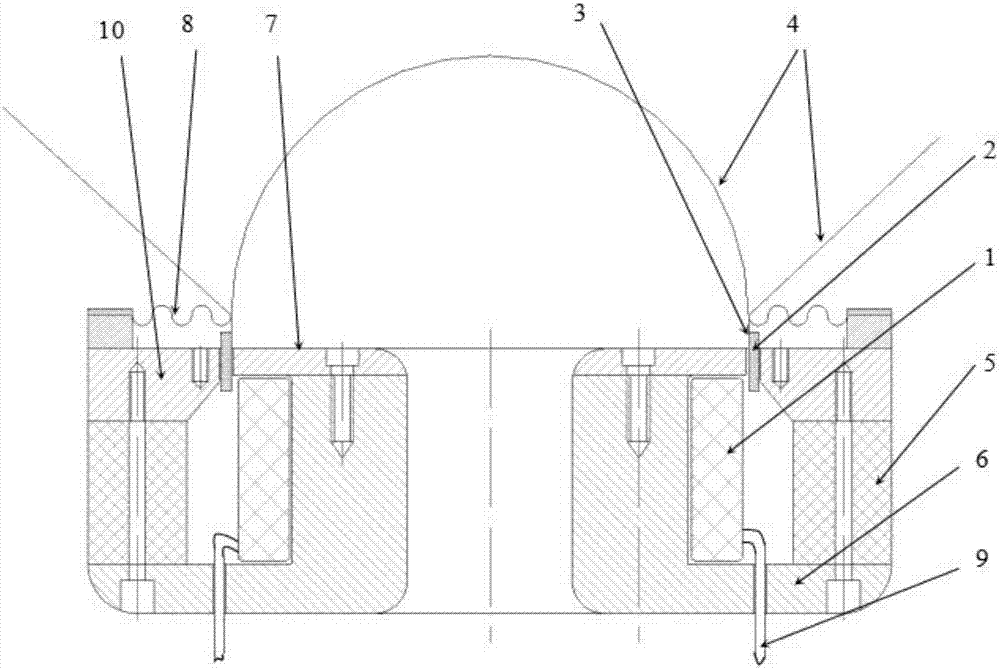

[0039] An external magnetic induction electrodynamic loudspeaker, such as figure 2 As shown, it includes excitation coil 1, induction voice coil 2, voice coil bobbin 3, sound film 4, magnetic steel 5, lower magnetic plate 6, upper magnetic splint 7, centering strut 8, signal feeder 9 and outer guide magnetic board10. The magnetic steel 5 is a high-resistivity permanent magnet, and the upper magnetically conductive splint 7, the lower magnetically conductive plate 6 and the outer magnetically conductive plate 10 are all soft magnetic materials with high magnetic permeability and high resistivity, which can reduce the eddy current loss of the magnetic circuit Small to increase the electro-acoustic conversion efficiency. The upper magnetically conductive splint 7 is installed on the upturned end surface of the lower magnetically conductive plate 6 and fixed together by bolts or glue, and the magnetic steel 5 is installed between the outer upper end surface of the lower magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com