Production technology of ellipsoidal suckling pig milk replacer

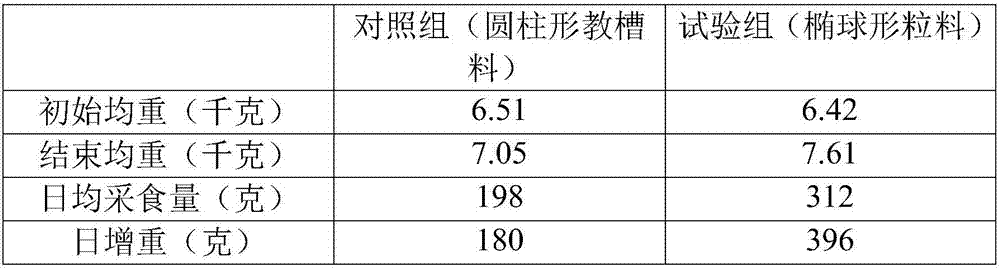

A production process and ellipsoidal technology, applied in the field of feed processing, can solve the problems of decreased nutrient utilization rate, heavy workload, deterioration of heat-sensitive raw materials, etc., and achieve the effects of less loss of nutritional value, reduced feed waste, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

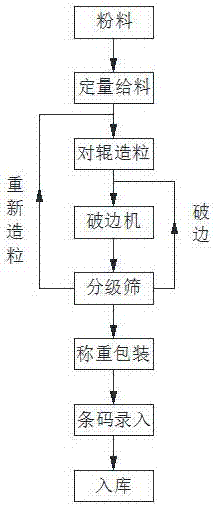

Method used

Image

Examples

Embodiment 1

[0026] 1) Put the powdered milk replacer with 20% lactose content, 10% white sugar content and 15% milk protein content into the silo through the elevator, and evenly transport the powder into the double-roll granulator through the quantitative feeder . The feeding rate of the quantitative feeder is 400kg / h;

[0027] 2) The roller granulator has two synchronous and reverse-rotating pressure rollers. The two pressure rollers are engraved with evenly arranged circular grooves. The diameter of the grooves is 5.0 mm and the maximum depth is 1.0 mm. Powdery The milk replacer passes through the gap between the two pressing rollers of the granulator, and will become a semi-finished product composed of ellipsoidal particles with a particle size of 5.5 mm and a height of 3.0 mm.

[0028] 3) The semi-finished product enters the edge breaking machine, the connection part between the particles is broken in the edge breaking machine, the ellipsoidal particles change from the connected sta...

Embodiment 2

[0032] 1) Put the powdered milk replacer with 35% lactose content, 12% white sugar content and 12% milk protein content into the silo through the elevator, and evenly transport the powder into the double-roll granulator through the quantitative feeder , the feeding rate of the quantitative feeder is 600kg / h;

[0033] 2) The roller granulator has two synchronous and reverse-rotating pressure rollers. The two pressure rollers are engraved with evenly arranged circular grooves. The diameter of the grooves is 8.0 mm and the maximum depth is 2.2 mm. After the milk passes through the gap between the two rollers of the granulator, it will become a semi-finished product composed of ellipsoidal particles with a particle size of 8.8 mm and a height of 5.4 mm.

[0034] 3) The semi-finished product enters the edge breaking machine, the connection part between the particles is broken in the edge breaking machine, the ellipsoidal particles change from the connected state to the scattered st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com