Factorized high-efficiency mushroom production culture material and preparation method thereof

A compost and industrialized technology, which is applied in the field of high-efficiency production of compost and its preparation in the industrialization of shiitake mushrooms, can solve the problems that are not the development direction and mainstream, difficult to ensure food safety, food safety hidden dangers, etc., to speed up the growth of bacteria, good application Prospects, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

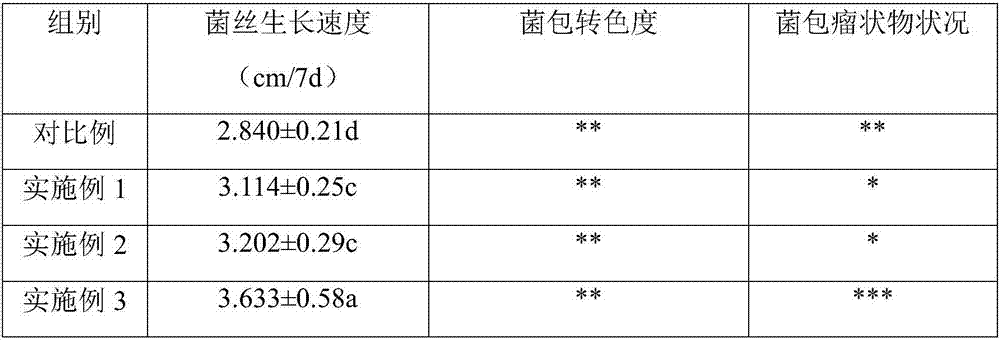

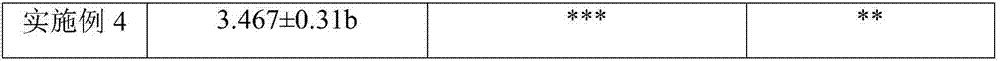

Embodiment 1

[0022] Weigh 78kg of sawdust (with a particle size of 50%K1+50%K2), 20kg of bran, and 2kg of gypsum, respectively, and add 150kg of water after mixing evenly. Stir the dry material evenly first, then add water and stir until completely mixed, so that the water content reaches 57%-62%, bottle it by machine, about 300g of dry material per bottle, autoclave at 121°C for 2 hours, mechanical inoculation factory Huxiang F2 (inoculum size 3% V / V), a special variety for shiitake mushroom production, was cultivated (cultivation conditions were temperature 23°C, humidity 65%-75%, CO 2 Concentration 1500ppm), after 30 days of fermentation, use a bottle digger to dig out the bottle, and use a briquetting machine to briquetting after digging the bottle. The briquetting size is 25.8cm*17.4cm*6.6cm, and the weight is about 2Kg. Secondary cultivation, color change, and then fruiting. After harvesting, culture bacteria, inject water and stimulate fruiting, and harvest two damp mushrooms. Dete...

Embodiment 2

[0024] Weigh 78kg of sawdust (with particle size of 50%K1+50%K3), 20kg of bran, and 2kg of gypsum, respectively, and add 150kg of water after mixing evenly. Stir the dry material evenly first, then add water and stir until completely mixed, so that the water content reaches 57%-62%, bottle it by machine, about 300g of dry material per bottle, autoclave at 121°C for 2 hours, mechanical inoculation factory Huxiang F2 (inoculum size 3% V / V), a special variety for shiitake mushroom production, was cultivated (cultivation conditions were temperature 23°C, humidity 65%-75%, CO 2 Concentration 1500ppm), after 30 days of fermentation, use a bottle digger to dig out the bottle, and use a briquetting machine to briquetting after digging the bottle. The briquetting size is 25.8cm*17.4cm*6.6cm, and the weight is about 2Kg. Secondary cultivation, color change, and then fruiting. After harvesting, culture bacteria, inject water and stimulate fruiting, and harvest two damp mushrooms. Determ...

Embodiment 3

[0026] Weigh 78kg of sawdust (33.33%K1+33.33%K2+33.33%K3), 20kg of bran, and 2kg of gypsum, mix them uniformly, and add 150kg of water. Stir the dry material evenly first, then add water and stir until completely mixed, so that the water content reaches 57%-62%, bottle it by machine, about 300g of dry material per bottle, autoclave at 121°C for 2 hours, mechanical inoculation factory Huxiang F2 (inoculum size 3% V / V), a special variety for shiitake mushroom production, was cultivated (cultivation conditions were temperature 23°C, humidity 65%-75%, CO 2 Concentration 1500ppm), after 30 days of fermentation, use a bottle digger to dig out the bottle, and use a briquetting machine to briquetting after digging the bottle. The briquetting size is 25.8cm*17.4cm*6.6cm, and the weight is about 2Kg. Secondary cultivation, color change, and then fruiting. After harvesting, culture bacteria, inject water and stimulate fruiting, and harvest two damp mushrooms. Determination of mycelium g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com