Solution processing-based uniform discrete type fluff sphere-like rubrene crystal growth method

A technology of solution processing and rubrene, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., to achieve the effect of simple operation, effective experimental means, and low film forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the examples, but the present invention is not limited.

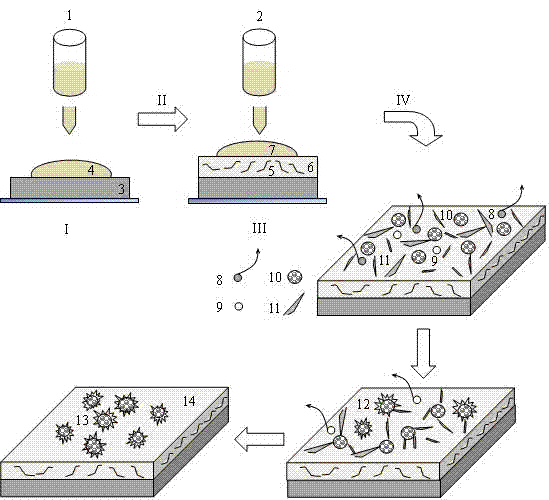

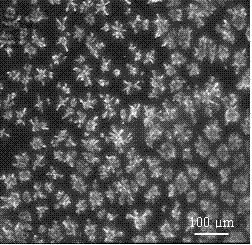

[0012] First prepare a 4.8 mg / ml rubrene solution (2) with tetrahydrofuran as a solvent and a 5 mg / ml polystyrene (PS) solution (1) with chloroform as a solvent, and ultrasonicate the prepared solution for 15 min to promote The solute is completely dissolved. Add 0.3 ml of high boiling point solvent N,N-dimethylformamide (DMF) dropwise to the sonicated rubrene solution. Then configure the piranha solution, the composition of the piranha solution is concentrated sulfuric acid with a volume ratio of 70:30: 30% hydrogen peroxide, and Si / SiO 2 The substrate (3) was soaked in piranha solution heated at 90 °C in a water bath for 25 minutes to carry out hydrophilic treatment of the substrate. After taking out the substrate, it was washed with acetone, ethanol, and deionized water respectively, and dried with nitrogen before being placed on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com