Production method of coconut oil fatty acid and coconut oil fatty acid produced by production method

A production method, coconut oil technology, applied in the field of deep processing of oils and fats, can solve problems such as inability to flexibly change the proportion of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

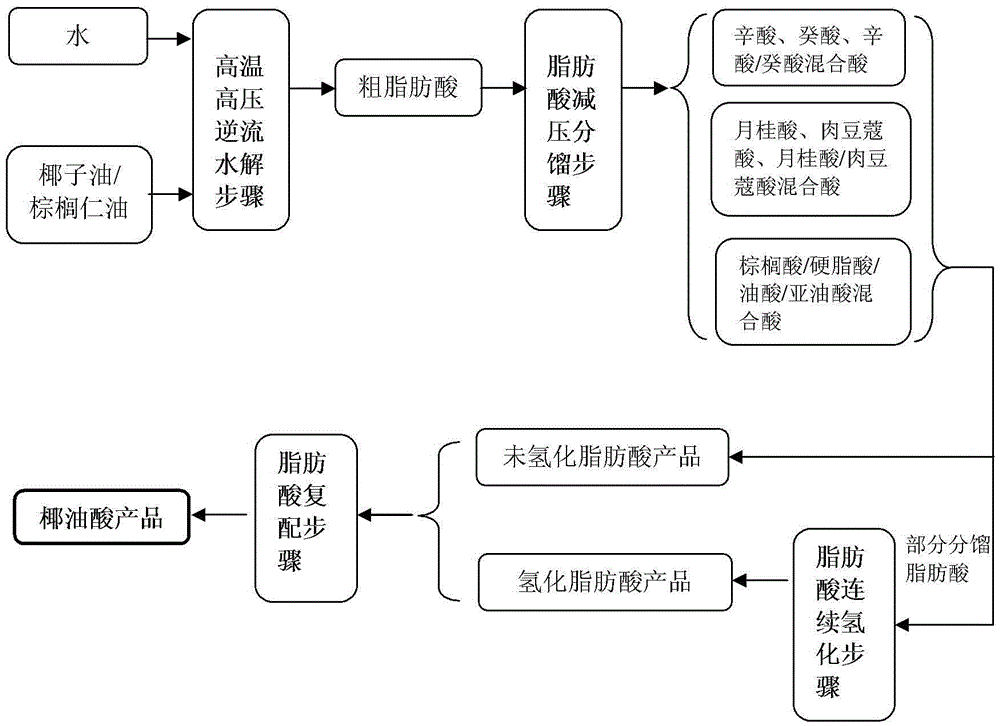

[0145] Such as figure 1 Shown technological process prepares coconut oil, specifically comprises the following steps:

[0146] 1) High temperature and high pressure countercurrent hydrolysis step

[0147] Select crude palm kernel oil (CPKO) as the raw material oil, and the index of this batch of CPKO is as follows: iodine value 19gI 2 / 100g, Lovibond color 60Y6R, free fatty acid (calculated as palmitic acid) 3.1%, moisture 0.25%, saponification value 247mgKOH / g, fatty acid component ratio: C6 0.21%, C8 2.99%, C10 3.05%, C1247.56% , C14 16.35%, C16 8.72%, C18:0 2.24%, C18:1 15.87%, C18:22.85%, other fatty acids 0.16%.

[0148] Send CPKO and water (including steam) into the hydrolysis equipment according to the mass ratio of 100:75, and maintain the reaction temperature at 250°C and the pressure at 5.2MPa to obtain crude fatty acid. Moisture and unhydrolyzed oils.

[0149] 2) Fatty acid vacuum fractionation step

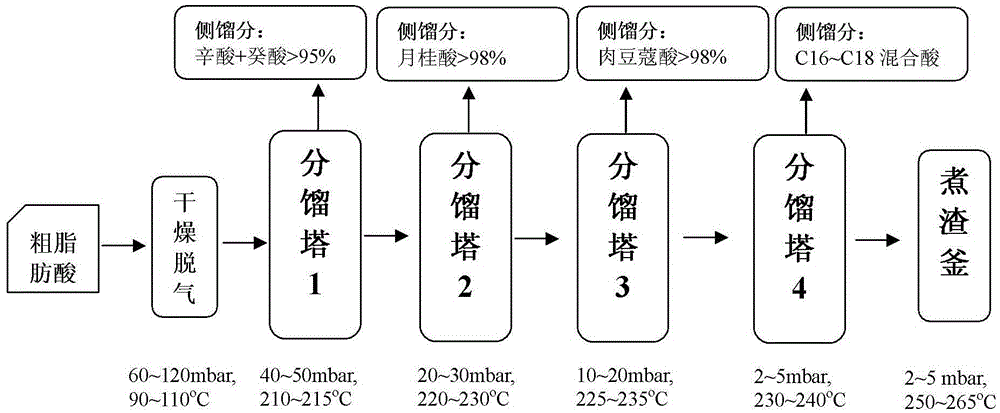

[0150] Then the crude fatty acid is sent into the dryer, mai...

Embodiment 2

[0159] It is basically the same as Example 1, except that the hydrogenated caprylic acid / capric acid mixed fatty acid product, lauric acid product, myristic acid product and unhydrogenated C16-C18 mixed fatty acid product are according to 1.5:5.0:1.7:1.8 The ratio is compounded to obtain a partially hydrogenated coconut oil product. Its index compares as shown in table 2 with the hydrogenated coconut oil product index that the conventional process shown in comparative example 2 produces.

[0160] From the data in Table 2, it can be found that the sample in the present embodiment, due to the special production process steps in the present embodiment, makes the color and luster of the product, thermal stability all significantly better than traditional coconut oil products, and the freezing point is lower than traditional coconut oil Acid products. The product of this embodiment is a mixture with a low freezing point, and at room temperature, it has better anti-separation perfo...

Embodiment 3

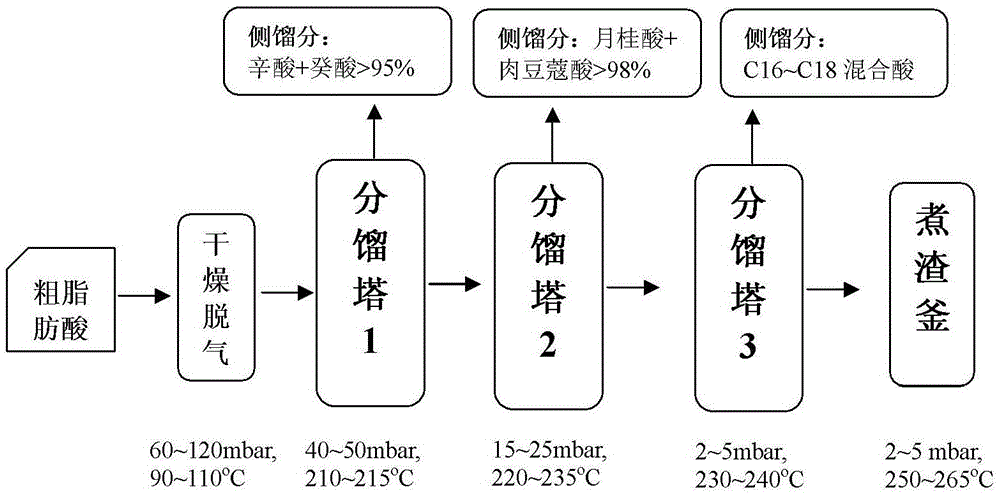

[0174] The flow process of this embodiment is different from that of Example 1 in that the fatty acid decompression fractionation step adopts 3 fractionation towers, according to image 3 Controlled by the process mode, a variety of fractionated fatty acid products can be obtained, including caprylic acid / capric acid mixed fatty acid (caprylic acid + capric acid mass content > 95%), lauric acid / myristic acid mixed fatty acid (lauric acid + myristic acid content > 98%) %), palmitic acid / stearic acid / oleic acid / linoleic acid mixed fatty acid (C16~C18 mixed fatty acid for short).

[0175] Correspondingly, in the fatty acid continuous hydrogenation step, the lauric acid / myristic acid mixed fatty acid is directly hydrogenated to obtain hydrogenated lauric acid / myristic acid mixed fatty acid.

[0176] In the fatty acid compounding step, the hydrogenated caprylic acid / capric acid mixed fatty acid product, lauric acid / myristic acid mixed fatty acid product and C16-C18 mixed fatty ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com