Method for preparing photocatalytic fluoride-free super-hydrophobic self-cleaning textile

A superhydrophobic and textile technology, applied in textiles and papermaking, liquid-repellent fibers, fiber treatment, etc., to improve self-cleaning performance, reduce optical fragility, and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: For pure cotton fabric, adopt preparation method of the present invention to prepare, specifically comprise the following steps:

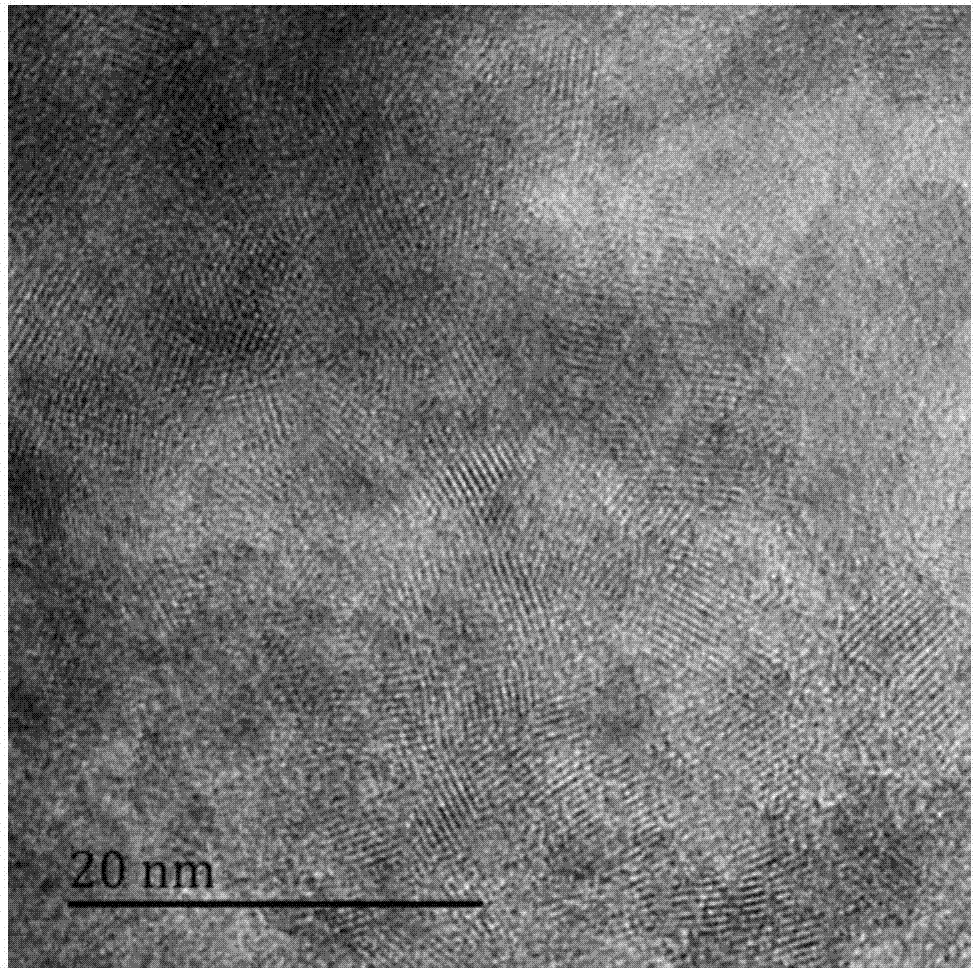

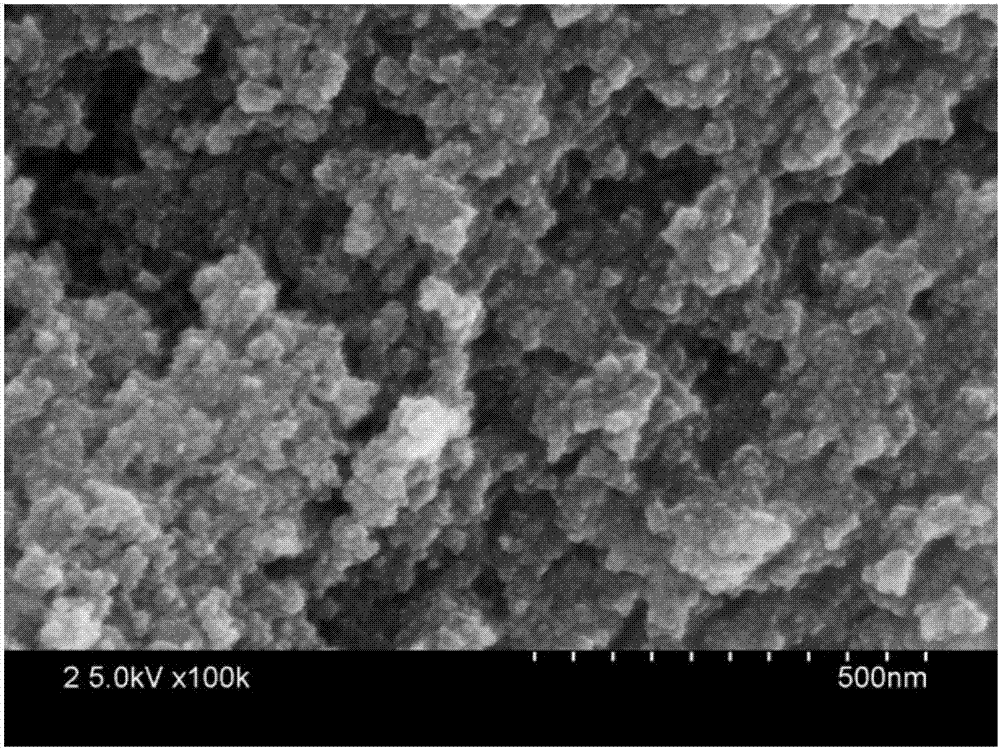

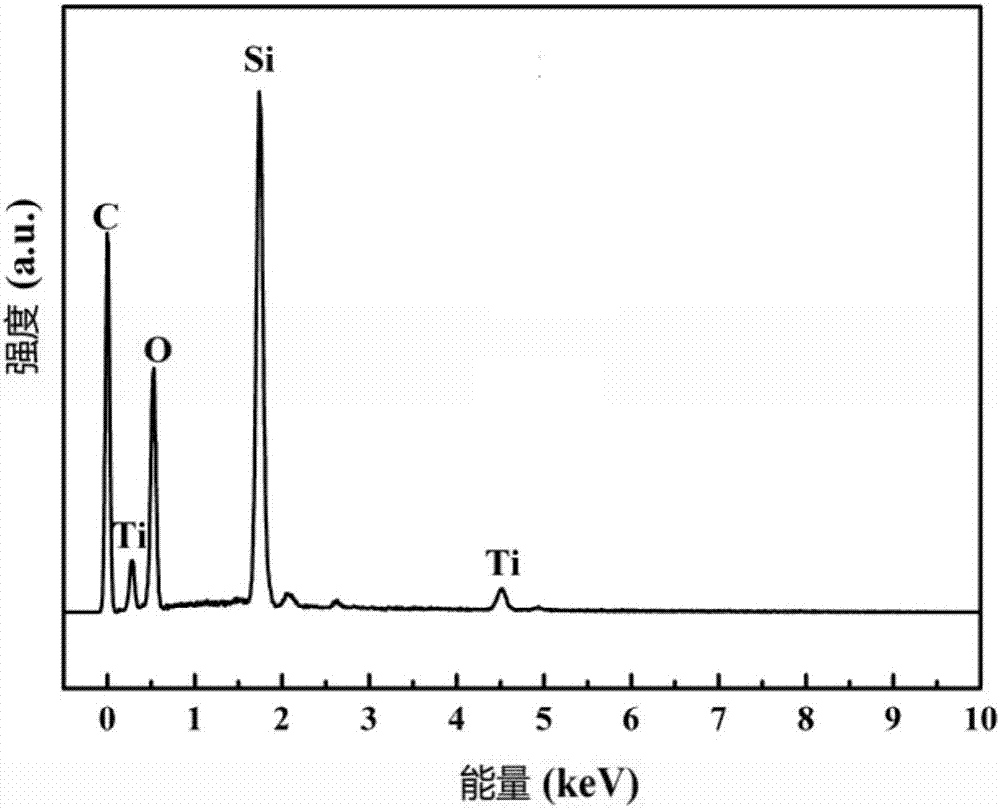

[0031] (1) At room temperature, weigh 2 g of hydrophobic silica nanoparticles, add them to 20 mL of benzyl alcohol with a mass concentration of 0.1 g / mL, and use an ultrasonic cell pulverizer for 3 minutes to obtain a silica dispersion; Slowly add 1 mL of titanium tetrachloride to the silica dispersion with a syringe, stir for 1 hour at room temperature, and then continue stirring for 6 hours at 60°C; then transfer the dispersion into a closed polytetrafluoroethylene container, And placed in an oven at 80°C for aging for 24 hours, a large amount of white precipitate was formed, which was centrifuged to obtain silica / titanium dioxide composite particles, which were washed with ethanol and tetrahydrofuran in sequence, and finally dried in an oven at 80°C for 12 hours, the photocatalytic superhydrophobic composite powder is obtain...

Embodiment 2

[0034] Embodiment 2: for polyester fabric, adopt preparation method of the present invention to prepare, specifically comprise the following steps:

[0035] (1) At room temperature, weigh 5g of hydrophobic silica nanoparticles, add them to 30mL of methanol with a mass concentration of 0.17g / mL, and use an ultrasonic cell pulverizer for 5 minutes to obtain a silica dispersion; use a syringe Slowly add 1 mL of titanium tetrachloride to the silica dispersion, stir at room temperature for 2 hours, then continue to stir at 60°C for 6 hours; then transfer the dispersion into a closed polytetrafluoroethylene container, and Aged in an oven at 80°C for 24 hours, resulting in a large amount of white precipitate, which was centrifuged to obtain silica / titanium dioxide composite particles, then washed with ethanol and tetrahydrofuran in sequence, and finally dried in an oven at 80°C for 12 hours , to obtain photocatalytic superhydrophobic composite powder;

[0036] (2) At room temperatur...

Embodiment 3

[0037] Embodiment 3: for polyester / cotton blended fabric, adopt preparation method of the present invention to prepare, specifically comprise the following steps:

[0038] (1) At room temperature, weigh 3 g of hydrophobic silica nanoparticles, add them to 30 mL of benzyl alcohol with a mass concentration of 0.1 g / mL, and use an ultrasonic cell pulverizer for 4 minutes to obtain a silica dispersion; Slowly add 1 mL of titanium tetrachloride to the silica dispersion with a syringe, stir at room temperature for 2 hours, then continue to stir at 60°C for 6 hours; then transfer the dispersion into a closed polytetrafluoroethylene container, And placed in an oven at 80°C for aging for 24 hours, a large amount of white precipitate was formed, which was centrifuged to obtain silica / titanium dioxide composite particles, which were washed with ethanol and tetrahydrofuran in sequence, and finally dried in an oven at 80°C for 12 hours, the photocatalytic superhydrophobic composite powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com