A lithium-sulfur battery electrolyte with improved battery capacity and preparation method thereof

A lithium-sulfur battery and battery capacity technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of lithium-sulfur battery capacity not playing a substantial role, poor long-term cycle of lithium-sulfur batteries, etc., to improve long-term cycle Performance, good commercialization prospects, simple preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

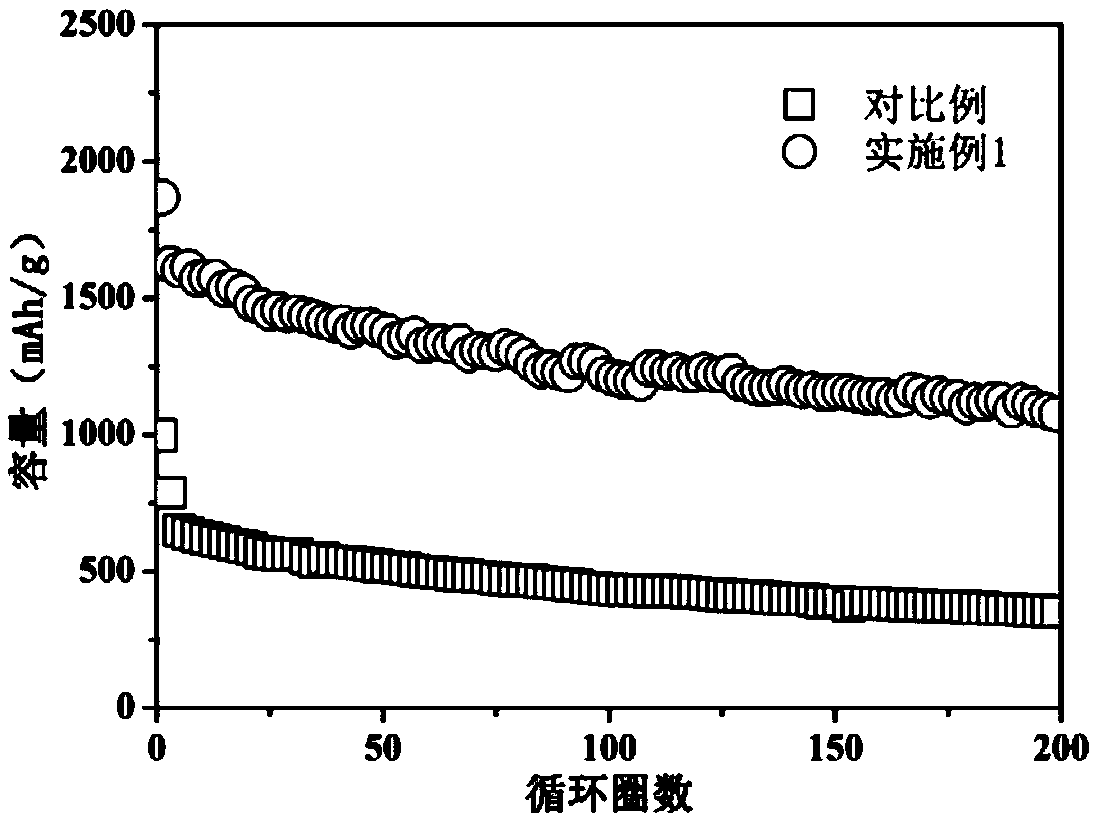

Embodiment 1

[0027] This embodiment provides a lithium-sulfur battery electrolyte and its configuration method for improving battery capacity, specifically:

[0028] (a) Under argon protection, measure 0.9 mL of 1,3-dioxolane (DOL, the first solvent) and 0.9 mL of ethylene glycol dimethyl ether (DME, the second solvent) in the glove box ) and mix, then add 0.2 mL of dimethyl trisulfide (DMTS, the third solvent), and mix well;

[0029] (b) Add 22.3 mg of anhydrous lithium nitrate additive (LiNO 3 ) and 558mg of lithium bistrifluoromethanesulfonylimide (LiTFSI); after fully mixing uniformly, the lithium-sulfur electrolyte is obtained; in the electrolyte, the concentration of LiTFSI is 1.0M, and LiNO 3 The mass percentage of DMTS is 1wt%, and the volume ratio of DMTS in the mixed solvent (also about the volume ratio of the total electrolyte) is 10vol%.

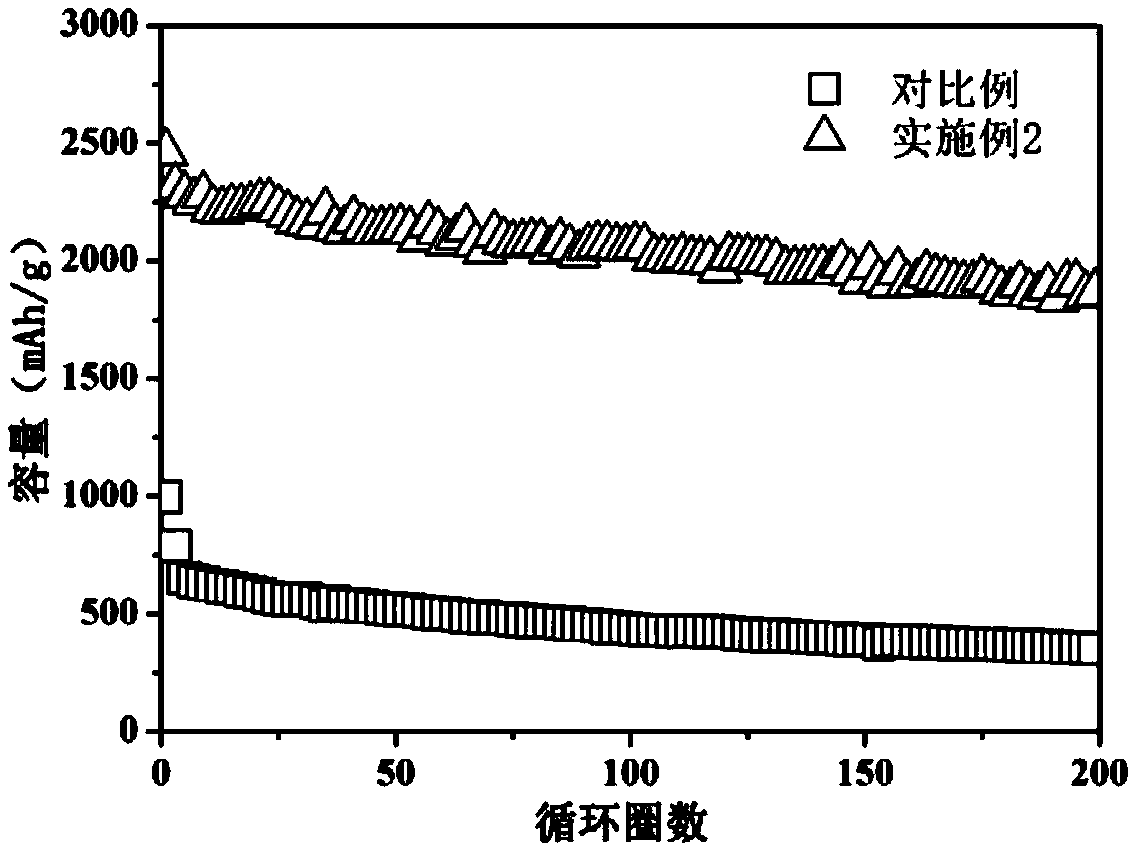

Embodiment 2

[0031] This embodiment provides a lithium-sulfur battery electrolyte and its configuration method for improving battery capacity, specifically:

[0032] (a) Under argon protection, measure and mix 0.8 mL of 1,3-dioxolane (DOL) and 0.8 mL of ethylene glycol dimethyl ether (DME) in a glove box, and then add 0.4 mL dimethyl trisulfide (DMTS), mix well;

[0033] (b) Add 22.3 mg of anhydrous lithium nitrate additive (LiNO 3 ) and 558 mg of lithium bistrifluoromethanesulfonylimide (LiTFSI); after mixing well, the lithium-sulfur electrolyte is obtained; in the electrolyte, the concentration of LiTFSI is 1.0 M, LiNO 3 The mass percentage of DMTS is 1 wt%, and the volume ratio of DMTS in the mixed solvent (also about the volume ratio of the total electrolyte) is 20 vol%.

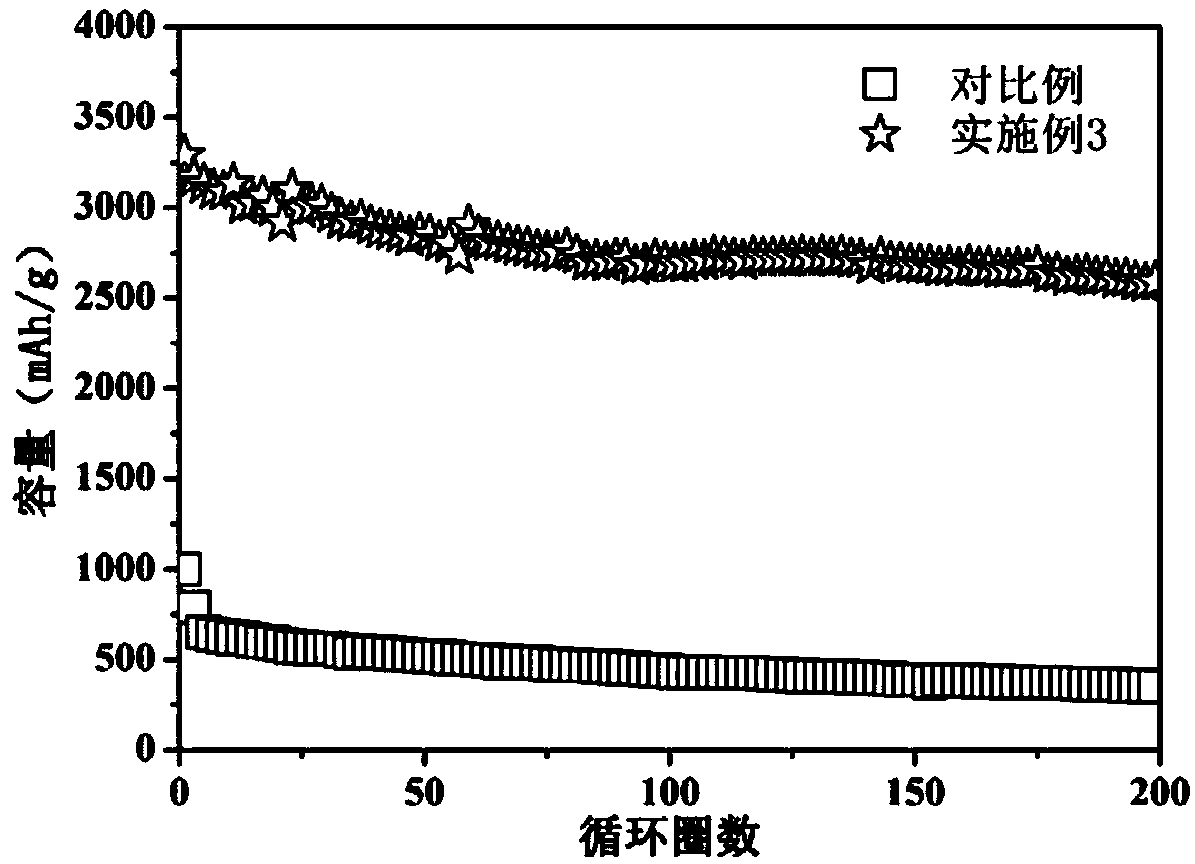

Embodiment 3

[0035] This embodiment provides a lithium-sulfur battery electrolyte and its configuration method for improving battery capacity, specifically:

[0036] (a) Under argon protection, measure and mix 0.7 mL of 1,3-dioxolane (DOL) and 0.7 mL of ethylene glycol dimethyl ether (DME) in a glove box, and then add 0.6 mL dimethyl trisulfide (DMTS), mix well;

[0037] (b) After mixing well, add 22.3 mg of anhydrous lithium nitrate additive (LiNO 3) and 558 mg of lithium bistrifluoromethanesulfonylimide (LiTFSI); after mixing well, the lithium-sulfur electrolyte solution is obtained. In the electrolyte, the concentration of LiTFSI is 1.0 M, LiNO 3 The mass percentage of DMTS is 1 wt%, and the volume ratio of DMTS in the total electrolyte (also about the volume ratio in the total electrolyte) is 30 vol%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com